High-performance aluminium alloy material for automatic transmission and preparation method thereof

An aluminum alloy material and high-performance technology, which is applied in the field of alloy materials, can solve problems such as slow reaction speed, oil pressure fluctuations, oil circuit collusion, etc., and achieve the goals of reducing porosity, improving mechanical properties, air tightness and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]A high-performance aluminum alloy material, the material is Al-Si-Cu aluminum alloy, the alloy contains the following elements in mass percentage: Si: 12%; Cu: 3.5%, rare earth element RE: 0.25%, The rest is Al. Prepare the aluminum alloy material according to the following specific steps:

[0038] A Fully preheat and bake the charge and smelting tools to remove impurities such as moisture and oil;

[0039] B mixes ingredients according to the formula and puts them into the melting furnace for smelting, in which rare earths only account for 1 / 2 of the total amount of rare earths;

[0040] C remove slag, purify, aluminum liquid is transferred to holding furnace;

[0041] D Preheat the remaining rare earth and add it to the molten aluminum in the holding furnace, stir it fully and let it stand for 20 minutes;

[0042] E-press mold vacuum treatment;

[0043] F blank die-casting.

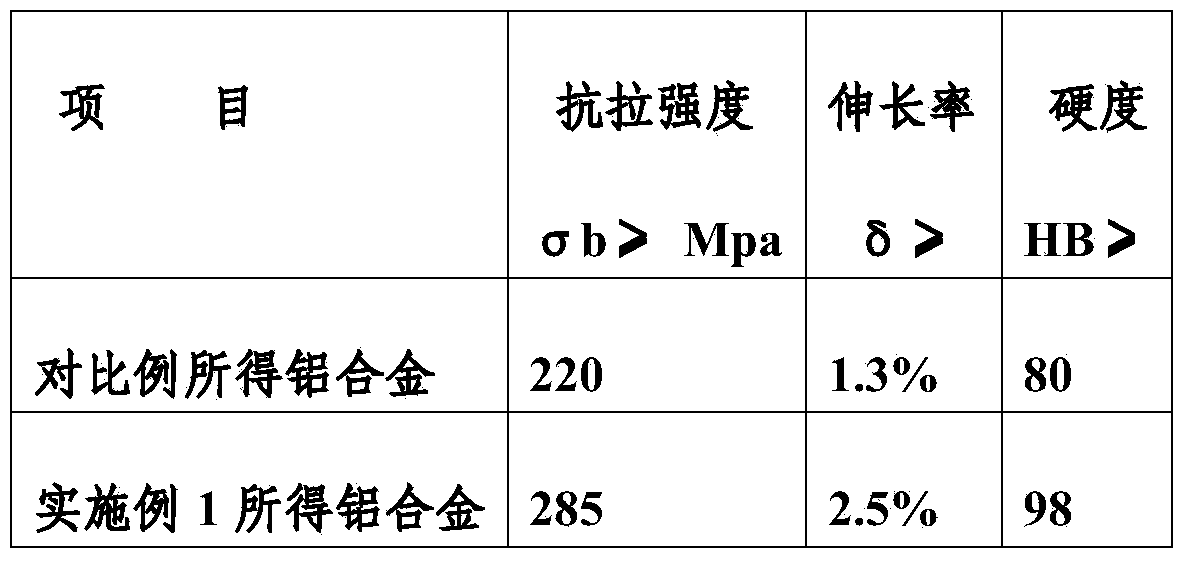

[0044] The above materials are used to manufacture the transmission oil pump, the valve p...

Embodiment 2

[0069] A high-performance aluminum alloy material, the mass percentage of each element in the alloy is as follows:

[0070] Si: 7.5%; Cu: 1.5%; Fe: 0.8%; Mn: 0.5%; Mg: 0.3%; Zn: 1.0%; Cr: 0.5%; Ni: 0.5%; Pb: 0.1%; RE: 0.3%; Sn: 0.1%, the rest is Al. Alloy materials and transmission oil pumps, valve plate assemblies, valve core assemblies, or engine water pumps were prepared according to the method described in Example 1. The tensile strength of the obtained material σ b ≥290Mpa, elongation δ≥2.8%, hardness HB≥100, porosity less than 0.1%, and thermal stability better than that of the material prepared in Example 1; the wear resistance, air tightness and service life of the corresponding product Also obviously improved with respect to embodiment 1.

Embodiment 3

[0072] In the formula described in Example 2, the content of each alloy element was individually adjusted, and the performance of the corresponding alloy material was investigated. The results show:

[0073] Silicon is the main element in most die cast aluminum alloys. It improves the castability of the alloy. Silicon and aluminum can form a solid solution. The formation of eutectics between silicon and aluminum can improve the high-temperature moldability of the alloy, reduce shrinkage, have no tendency to thermal cracking, and have high corrosion resistance. However, when the silicon content in the alloy exceeds the eutectic composition, and there are many impurities such as copper and iron, hard spots of free silicon will appear, making cutting and processing difficult, and the high-silicon aluminum alloy has a serious corrosion effect on the casting crucible.

[0074] Copper and aluminum form a solid solution, which has the functions of solid solution strengthening and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com