High strength 7xxx aluminum alloys and methods of making the same

A technology of aluminum alloy and aluminum alloy products, applied in aircraft control, transportation and packaging, seat arrangement, etc., can solve difficult problems and achieve high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Twelve alloys were prepared for strength and elongation testing (see Table 4). Alloys V1, V2, V3, V4, V5, V6, V7, V8, V9, V10, V11, and V12 were prepared according to the methods described herein. The elemental composition of the alloys tested is shown in Table 4, the balance being aluminum. The elemental compositions are given in weight percent. Alloy V3 is an existing AA7075 alloy and is used for comparison purposes. Alloys V1, V2, V4, V5, V6, V7, V8, V9, V10, V11, and V12 were prototype alloys prepared according to the methods described herein.

[0098] Table 4

[0099] alloy Zn Cu Mg Fe Si Zr mn Cr Ti V1 8.03 2.07 1.68 0.13 0.07 0.10 0.04 0.03 0.003 V2 8.20 2.31 1.79 0.30 0.20 0.12 0.03 0.03 0.028 V3 5.43 1.47 2.48 0.19 0.09 0.003 0.02 0.17 0.005 V4 5.94 1.68 2.57 0.19 0.09 0.12 0.03 0.04 0.02 V5 6.77 2.18 2.45 0.10 0.09 0.12 0.03 0.04 0.004 V6 8.98 0.30 2.31 0.20 ...

Embodiment 2

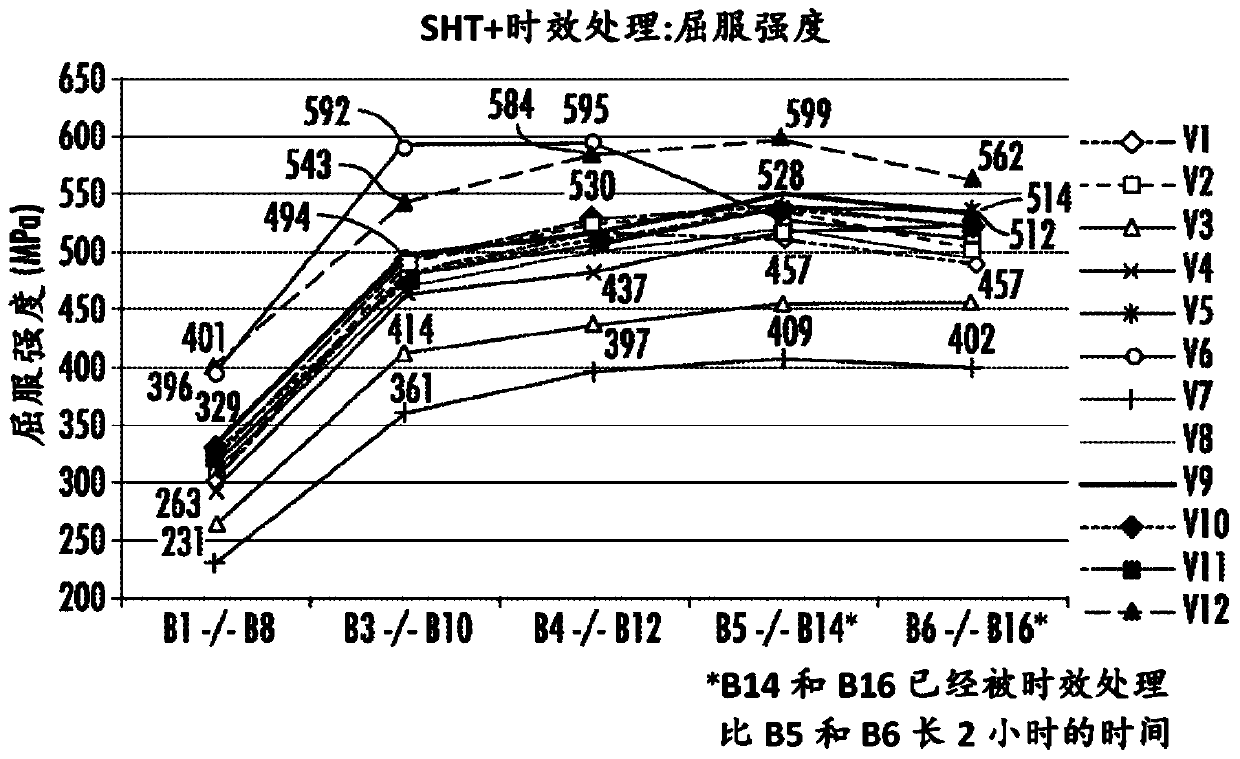

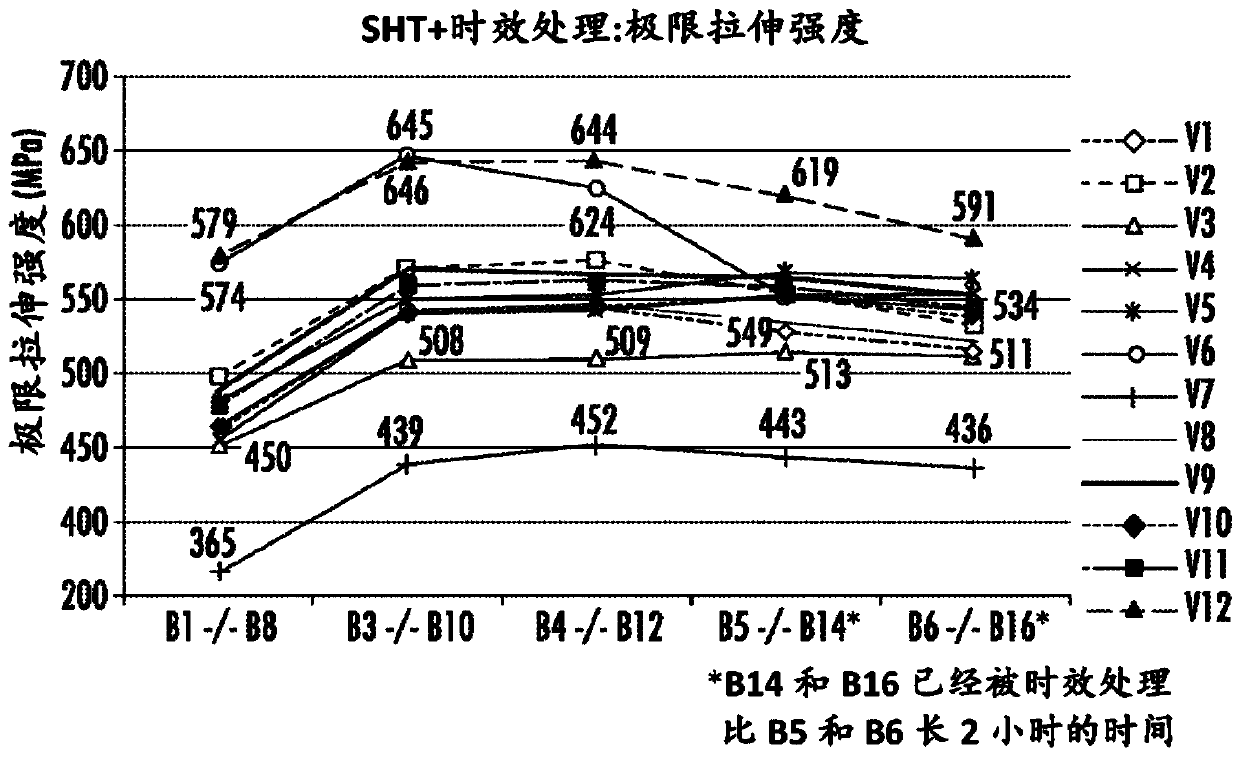

[0119] Sheets prepared using warm water quenching in Example 1 were aged according to the conditions described below in Table 10 (ie, B1, B3, B4, B5, B6, B8, B10, B12, B14, and B16). Specifically, sheets prepared from alloys V1, V2, V3, V5, V11, and V12 were aged according to each of the conditions described for aging operations B1, B3, B4, B5, and B6 . Sheets prepared from alloys V4, V6, V7, V8, V9, and V10 were aged according to each of the conditions described for aging operations B8, B10, B12, B14, and B16. As described in Table 10, the sheet was heated from room temperature (about 25°C) to about 120°C at a rate of 16°C / hour. The sheet was then maintained at about 120°C for 6 hours. Sheets aged according to aging operations B4, B5, B6, B12, B14, and B16 were further heated from 120°C to 155°C at a rate of 11.7°C / hour. The sheet was maintained at about 155°C for the period of time indicated in Table 10 as "Second Soak Time". The sheet was then cooled to room temperature...

Embodiment 3

[0130] Sheets prepared from alloys V1 to V12 were aged by heating to a temperature of 125° C. for 24 hours. The resulting yield strength was measured and the results are shown in Table 13 below. For comparison purposes, the peak aged yield strengths are also listed in Table 13.

[0131] Table 13

[0132] Peak aging yield strength (MPa) Yield strength after aging treatment at 125°C for 24 hours (MPa) V1 518 520 V2 534 537 V3 457 434 V4 517 503 V5 541 513 V6 592 624 V7 409 420 V8 517 523 V9 549 540 V10 530 541 V11 542 535 V12 599 579

[0133] Strength data obtained after aging at 125°C for 24 hours ("125°C data") showed considerable variability compared to peak aged strength data. For example, the 125°C data for the V6 sample showed a significant increase in yield strength compared to the peak aged strength data. However, the 125°C data for the V5 sample showed a significant decrease in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com