Method for producing wind-electricity principal axis with gathering stock full fibre upset forging

A wind power main shaft, all-fiber technology, applied in wind power generation, wind turbine components, shafts, etc., can solve the problems of deterioration of main shaft working conditions, and achieve the effect of improving fatigue resistance, simple operation and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

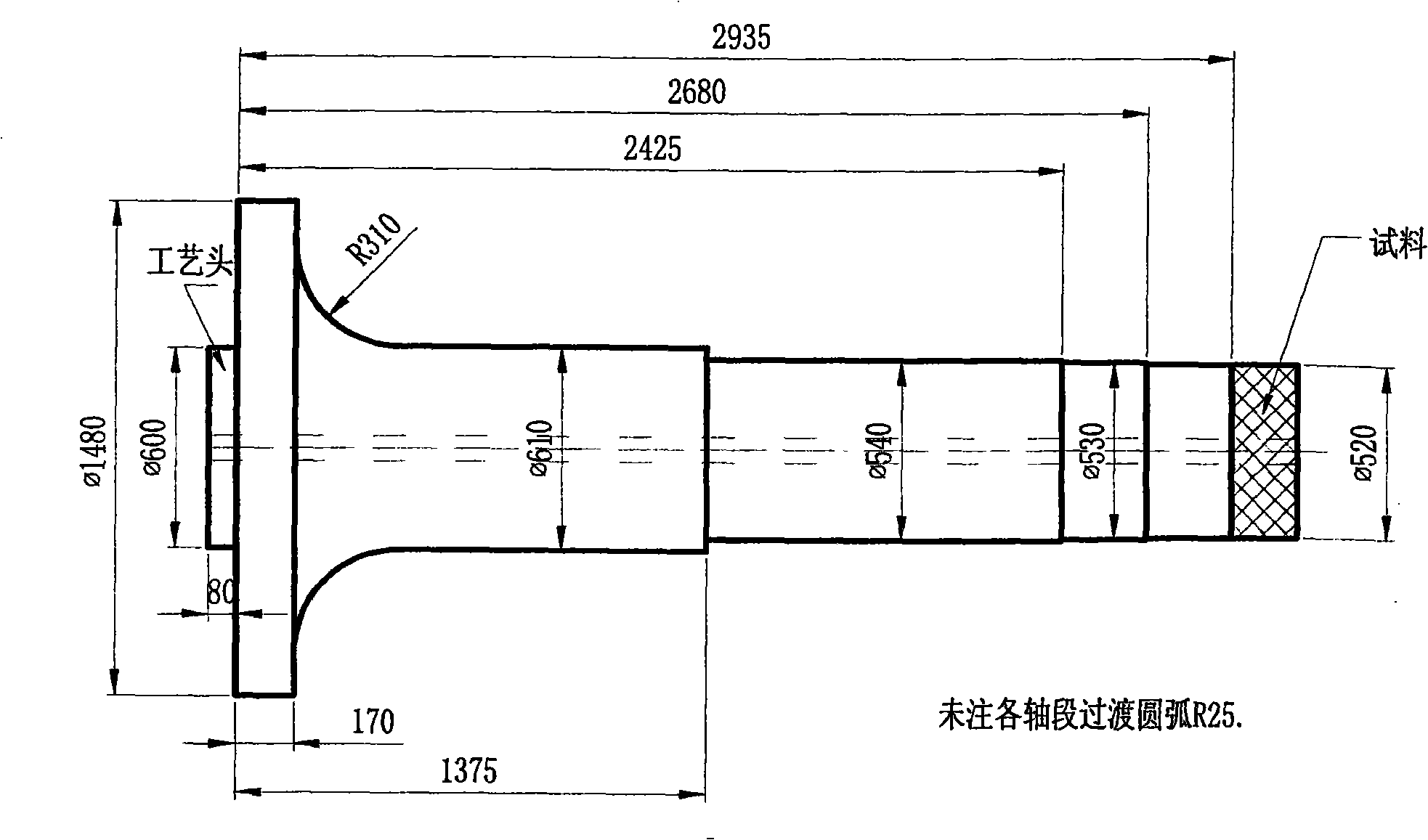

[0043] Let's take a product of a customer as an example to illustrate the whole process of wind power spindle production. Spindle is divided into normal temperature type and cold type according to the different ambient temperature. Because there are many cold types in actual production, it is more typical, so take the cold type wind power spindle as an example.

[0044] 1. The main technical requirements of the spindle

[0045] Spindle forgings are produced, inspected and accepted according to the technical conditions of DW812A3002B-2005:

[0046] 1. For the spindle delivery diagram provided by the customer, see image 3 .

[0047] Overall forging ratio requirement: Y≥3.5.

[0048] 2. Material and chemical composition

[0049] Material: 34CrNiMo6+QT

[0050] Chemical composition (%): Acceptance according to DIN1720 standard.

[0051] C 0.30~0.38, Si≤0.40, Mn0.50~0.80, P≤0.035, S≤0.035, Cr1.30~1.70, Mo 0.15~0.30, Ni1.30~1.70.

[0052] 3. Ultrasonic flaw detection:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Σ0.2 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com