High-strength aluminum alloy extruded material with excellent corrosion resistance and method of producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0051] An aluminum alloy having a composition shown in Table 1 was cast by semicontinuous casting to prepare a billet with a diameter of 100 mm. The billet was homogenized at 525° C. for eight hours to prepare an extrusion billet.

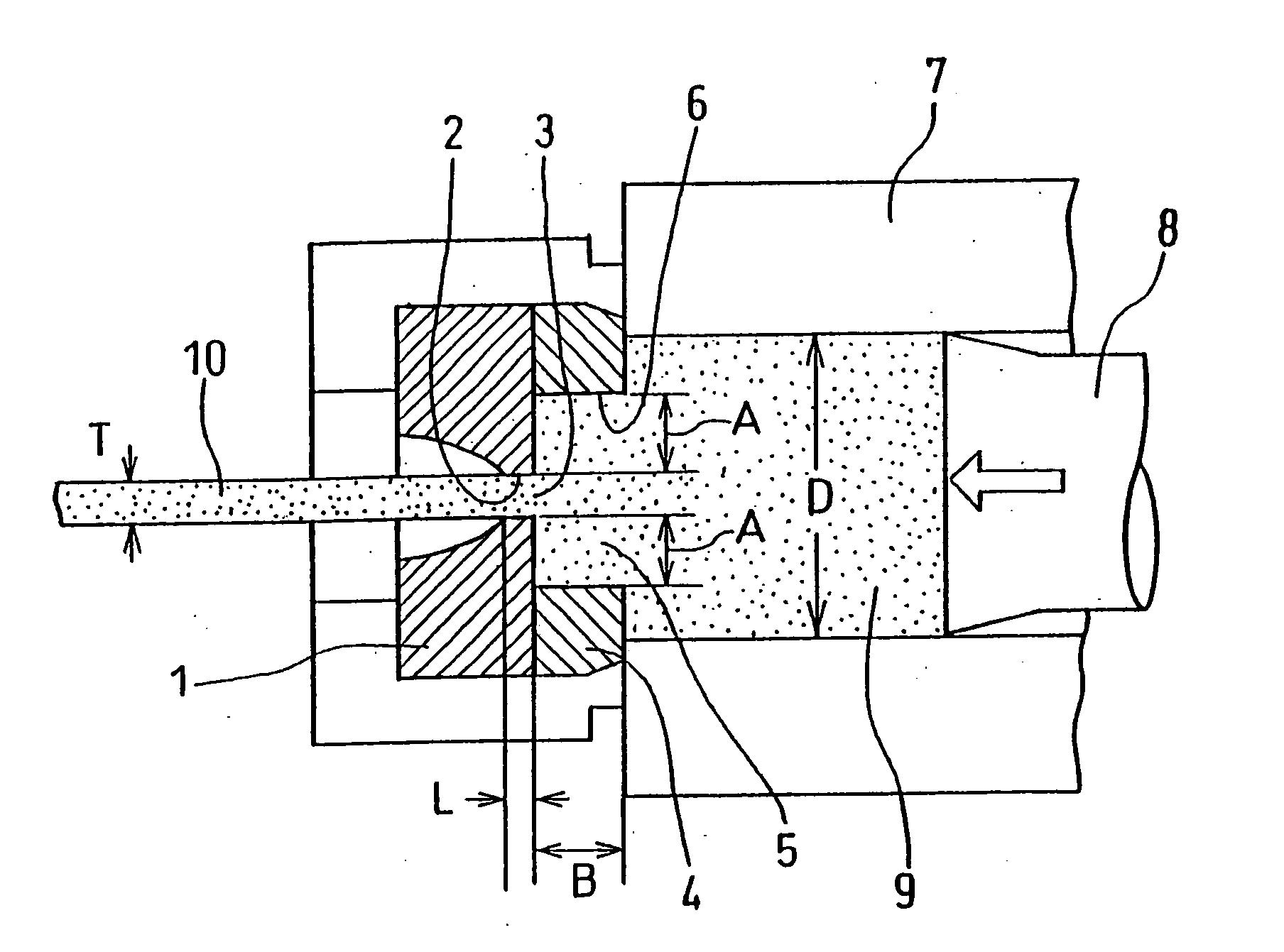

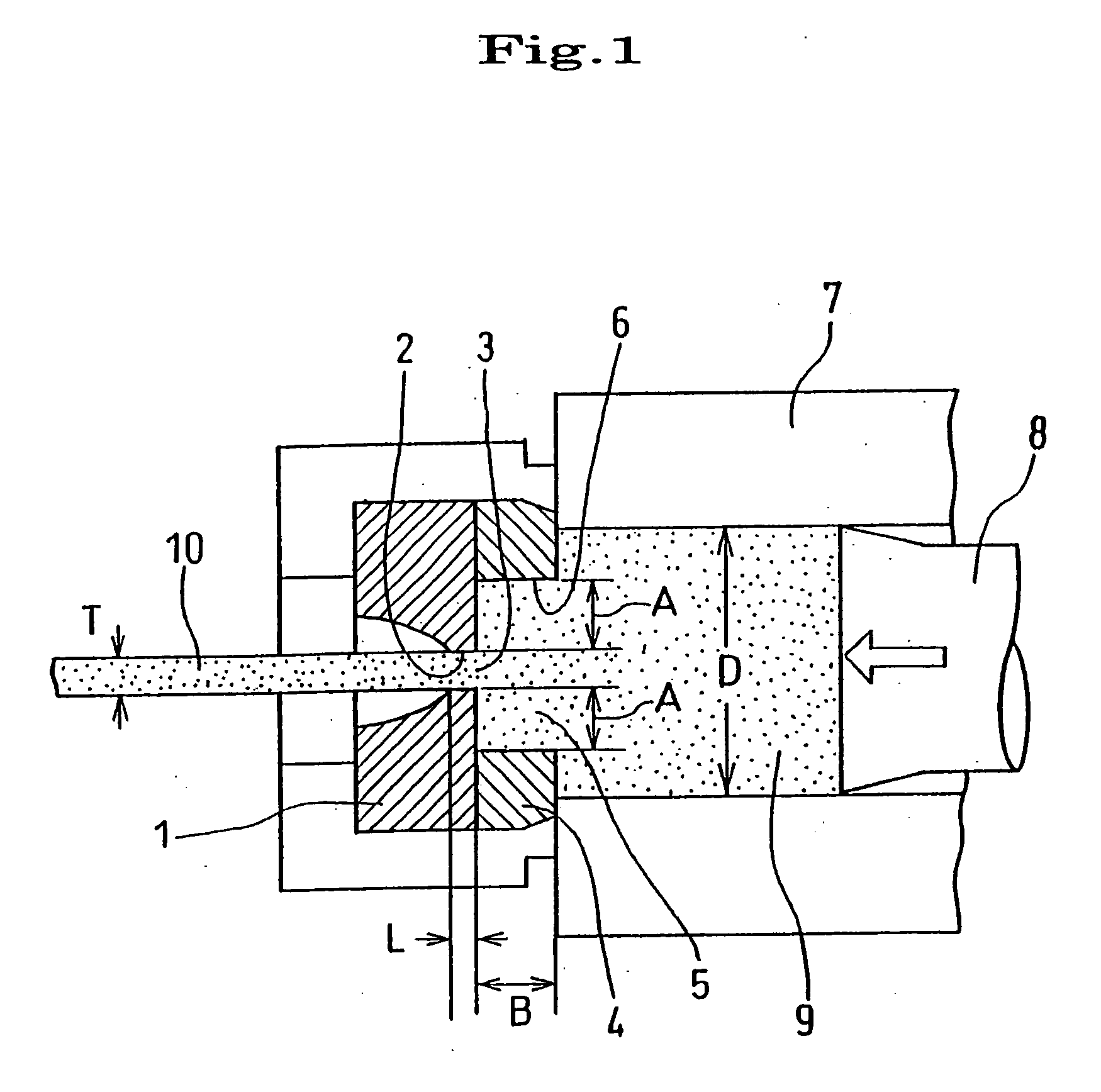

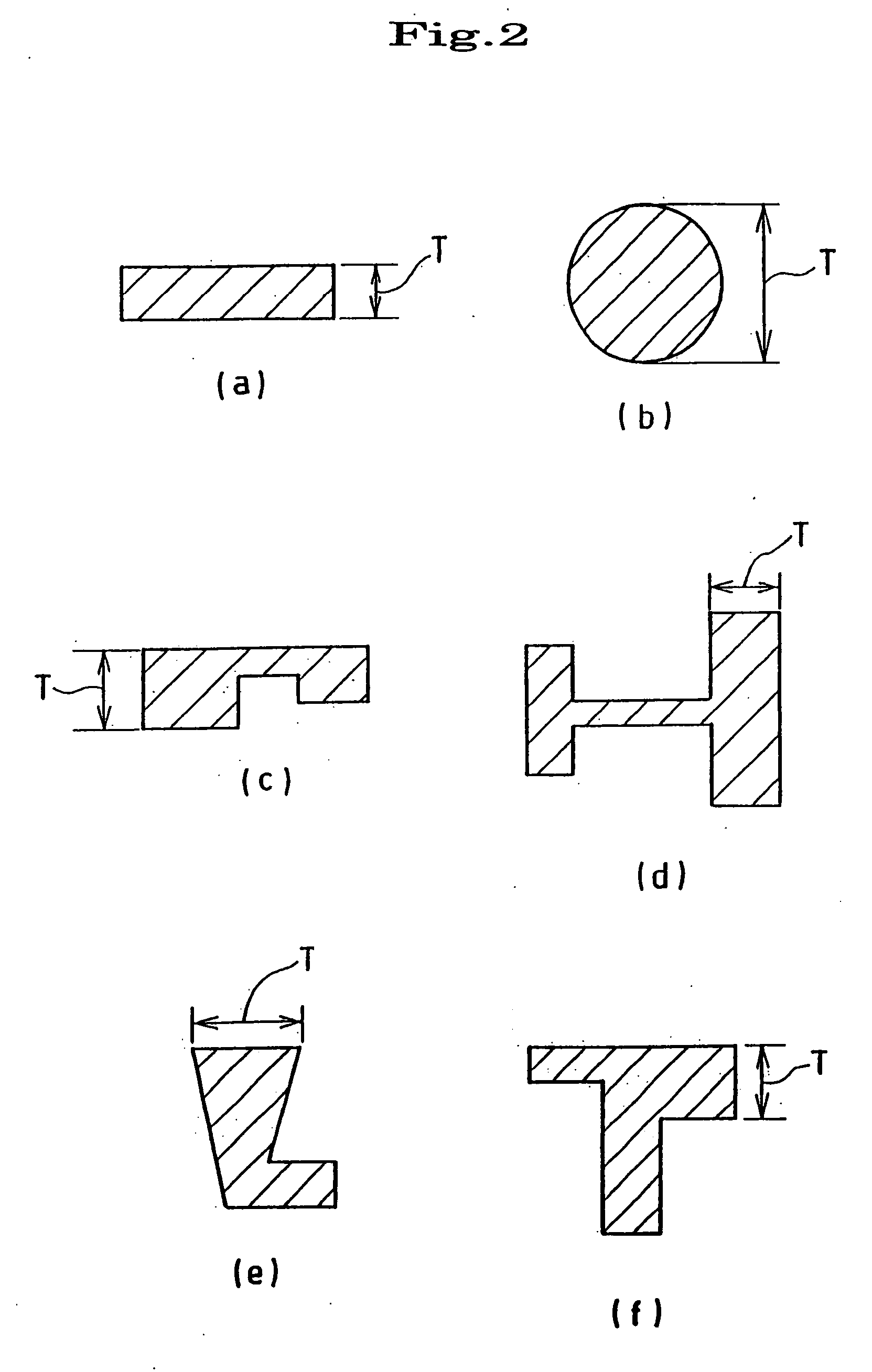

[0052] The extrusion billet was heated to 480° C. and extruded by using a solid die at an extrusion ratio of 27 and an extrusion rate of 3 m / min to obtain a quadrilateral solid extruded product having a thickness of 12 mm and a width of 24 mm. The solid die had a bearing length of 6 mm, and the corners of an orifice were rounded off with a radius of 0.5 mm. A flow guide attached to the die had a quadrilateral guide hole. The distance (A) from the inner circumferential surface of the guide hole to the outer circumferential surface of the orifice was set at 15 mm, and the thickness (B) of the flow guide was set at 15 mm with respect to the billet diameter of 100 mm (B=15% of billet diameter).

[0053] The resulting solid extruded product was subjected to a sol...

example 2

[0063] The aluminum alloy A having the composition shown in Table 1 was cast by semicontinuous casting to prepare a billet with a diameter of 100 mm. The billet was homogenized at 500° C. and extruded into a quadrilateral solid extruded product (thickness: 12 mm, width: 24 mm) by using a solid die having a bearing length shown in Table 5. The extrusion temperature was 480° C. except for a specimen No. 34 (430° C.), and the extrusion rate was 3 m / min.

[0064] The solid extruded product was subjected to press quenching or quenching under conditions shown in Table 5, and was heat treated under the same conditions as in Example 1 to obtain T6 temper material. In Table 5, the quenching cooling rate is the average cooling rate from the solution heat treatment temperature to 100° C. A controlled atmosphere furnace was used for the solution heat treatment.

[0065] The resulting T6 material was used as a specimen and subjected to (1) grain size measurement in the cross section perpendicular to...

example 3

[0073] An aluminum alloy having a composition shown in Table 1 was cast by semicontinuous casting to prepare a billet with a diameter of 200 mm. The billet was homogenized at 525° C. for eight hours to prepare an extrusion billet. The extrusion billet was extruded (extrusion ratio: 20) into a tubular product having an outer diameter of 30 mm and an inner diameter of 20 mm at an extrusion temperature of 480° C. and an extrusion rate of 3 m / min by using a porthole die in which the ratio of the chamber depth D to the bridge width W was 0.5 to 0.6. The ratio of the flow speed of the aluminum alloy in the joining section of the die to the flow speed of the aluminum alloy in the non-joining section was 1.3 to 1.4.

[0074] The resulting tubular extruded product was subjected to a solution heat treatment by heating the extruded product to 530° C. at a temperature rise rate of 10° C. / sec, and subjected to water quenching within 10 seconds after completion of the solution heat treatment. The q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com