High strength aluminum alloy casting and method of production of same

a technology of aluminum alloy and high strength, applied in the field of high strength aluminum alloy casting, can solve the problems of inability to meet the design requirements of aluminum alloy scrolls, inferior properties, etc., and achieve the effects of high strength, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

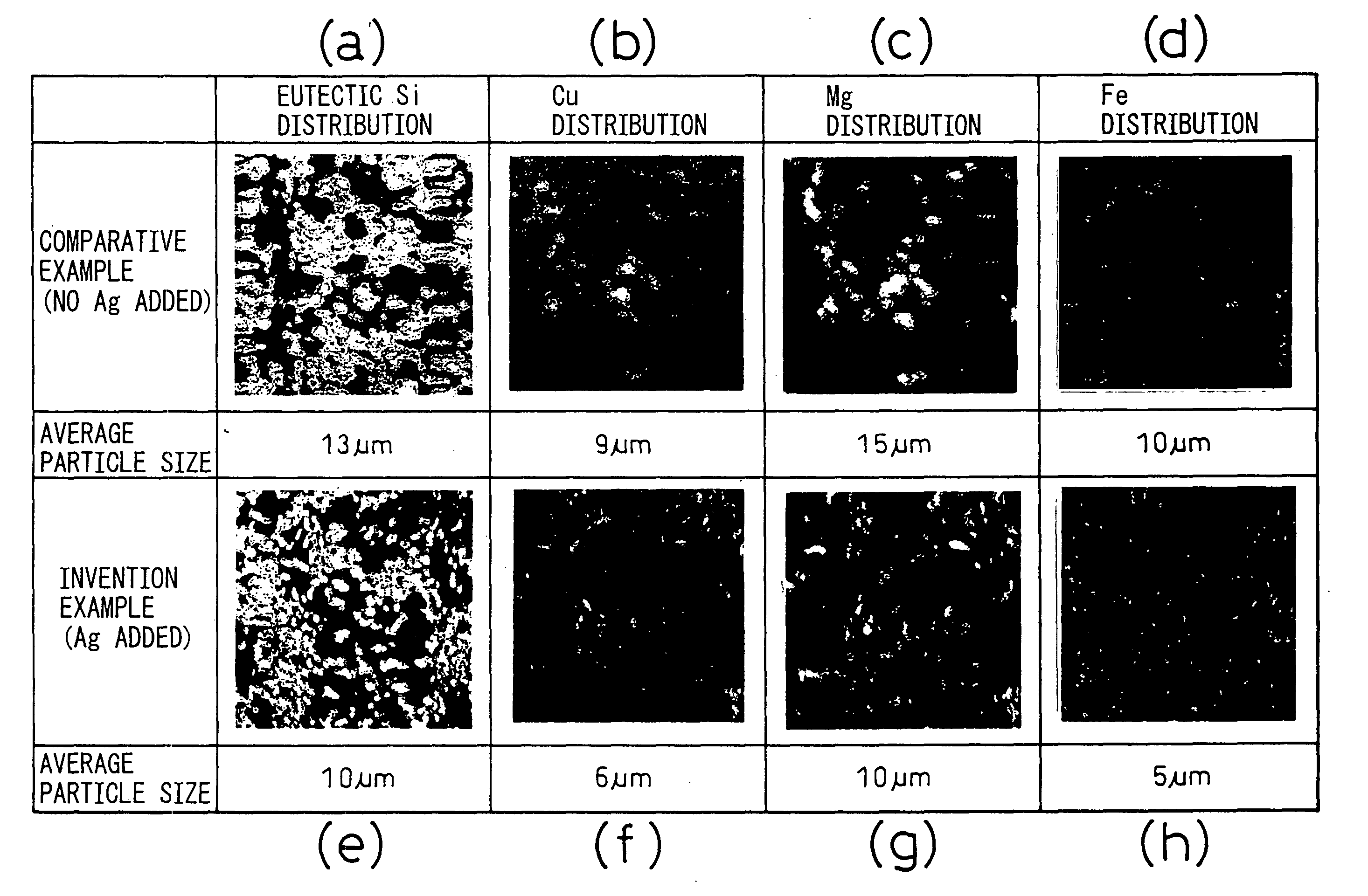

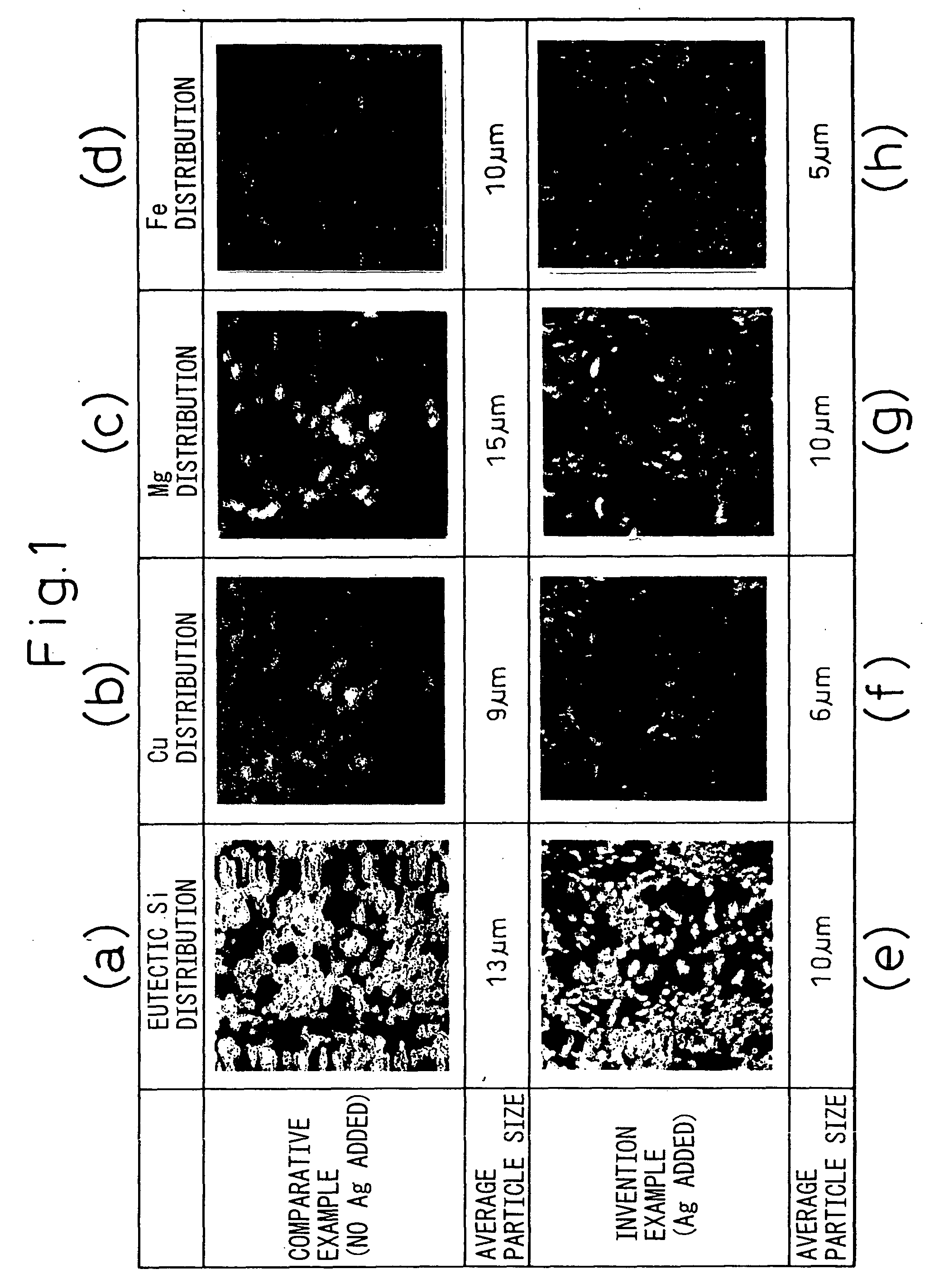

Method used

Image

Examples

example 1

[0058] An alloy containing 10.5 wt % of Si, 4.5 wt % of Cu, 0.6 wt % of Mg, 0.5 wt % of Fe, 0.4 wt % of Mn, unavoidable impurities, and the balance of Al and further containing 0.2 wt % of Ag was prepared.

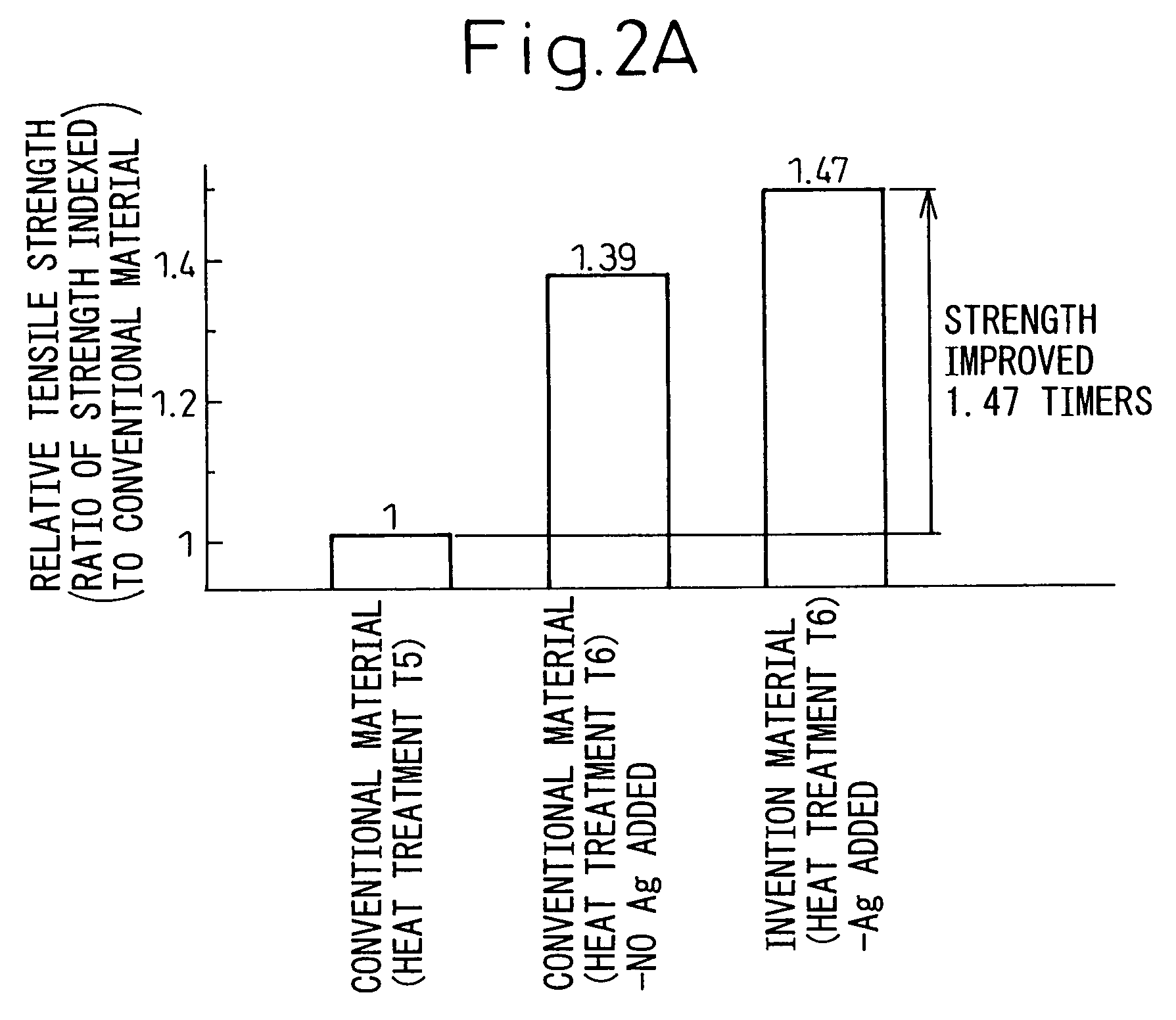

[0059] A melt of the aluminum alloy was die cast into a scroll for a compressor of an air-conditioner using a conventional die cast machine. After release from the mold, the casting of the scroll of the aluminum alloy was solubilized by heating in a temperature range of 495 to 505° C. for 2 to 6 hours. The solubilized casting of the scroll was then water quenched in the present example. After water quenching, the casting of the scroll was age hardened by heating in a temperature range of 160 to 220° C. for 2 to 6 hours. The casting of the scroll for a compressor of an air-conditioner obtained could be increased in tensile strength, yield strength, and fatigue strength by about 5 to 15%.

example 2

[0060] In this embodiment, first the inside of the mold of a die cast machine was reduced in pressure to not more than 13.3 kPa (100 Torr) using a vacuum pump. The casting of the scroll of the aluminum alloy taken out from the mold, like in Example 1, was solubilized by heating in a temperature range of 495 to 505° C. for 2 to 6 hours and then, in the present example, water quenched and age hardened by heating in a temperature range of 160 to 220° C. for 2 to 6 hours. Even if subjecting the casting of the scroll for a compressor of an air-conditioner obtained to the above high temperature, long solubilization and age hardening, the entrainment of gas was suppressed by evacuating the inside of the mold at the time of die casting, so there was less blistering and no problem of a drop in strength.

example 3

[0061] In this example, in the same way as in Example 2, the atmosphere was adjusted by reducing the pressure inside of the mold of the die cast machine to not more than 13.3 kPa (100 Torr) using a vacuum pump, then blowing oxygen of at least atmospheric pressure into the mold. The melt of aluminum alloy shown in Example 1 was filled in the mold to die cast a scroll for a compressor of an air-conditioner. The casting of the scroll of an aluminum alloy taken out from the mold, like in Example 1, was solubilized by heating in a temperature range of 495 to 505° C. for 2 to 6 hours and then, in the present example, water quenched and age hardened by heating in a temperature range of 160 to 220° C. for 2 to 6 hours. Even if subjecting the casting of the scroll for a compressor of an air-conditioner obtained to the above high temperature, long solubilization and age hardening, the entrainment of gas was suppressed by evacuating the inside of the mold and blowing in oxygen at the time of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com