Method for manufacturing high-strength aluminum alloy material for vehicle heat exchanger

An aluminum alloy material and heat exchanger technology, which is applied in the field of high-strength aluminum alloy materials, can solve the problems of uneven waveform height, uneven deformation, and roughening of heat sink materials, so as to improve strength and corrosion resistance, and inhibit corrosion. , the effect of inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0024]A first embodiment of the method of manufacturing an aluminum alloy material of the present invention will be described below.

[0025] In the production method of the present embodiment, a molten aluminum alloy is used, which contains Si: 0.3% to 1.2%, Fe: 0.7% to 2.0%, Mn: 0.2% to 0.8%, Zn: 0.1% to 1.0% by mass. %, and the remainder containing Al and unavoidable impurities.

[0026] The composition of aluminum alloy materials

[0027] Next, the numerical limits of the composition of the aluminum alloy material determined in the present embodiment will be described in detail.

[0028] Si: 0.3% to 1.2% (more preferably 0.8% to 1.0%)

[0029] Silicon (Si), which coexists with Mn in the form of an Al-Mn-Si compound, is dispersed in the matrix or forms a solid solution, and has the effect of increasing the strength of the aluminum alloy material.

[0030] The content of Si is preferably 0.3% to 1.2% by mass, more preferably 0.8% to 1.0%.

[0031] When the content of...

no. 2 approach

[0132] A second embodiment of the method of manufacturing an aluminum alloy material of the present invention will be described below.

[0133] In the production method of the present embodiment, a molten aluminum alloy is used, which contains Si: 0.3% to 1.2%, Fe: 0.05% to less than 0.7%, Mn: more than 0.8% to 2.0%, Zn: 0.5% by mass. %~4.0%, and the rest containing Al and unavoidable impurities.

[0134] The composition of aluminum alloy materials

[0135] Next, the numerical limits of the composition of the aluminum alloy material determined in the present embodiment will be described in detail.

[0136] Si: 0.3% to 1.2% (more preferably 0.4% to 1.2%)

[0137] Silicon (Si), which coexists with Mn in the form of an Al-Mn-Si compound, is dispersed in the matrix or forms a solid solution, and has the effect of increasing the strength of the aluminum alloy material.

[0138] The content of Si is preferably 0.3% to 1.2% by mass, more preferably 0.4% to 1.2%.

[0139] When...

Embodiment A

[0213] The manufacturing method and evaluation test items of the aluminum alloy material of Example A will be described.

[0214] Manufacturing method

[0215] In Example A, an aluminum alloy material was produced using an aluminum alloy having the composition shown in Table 1 under the production conditions shown in Table 2.

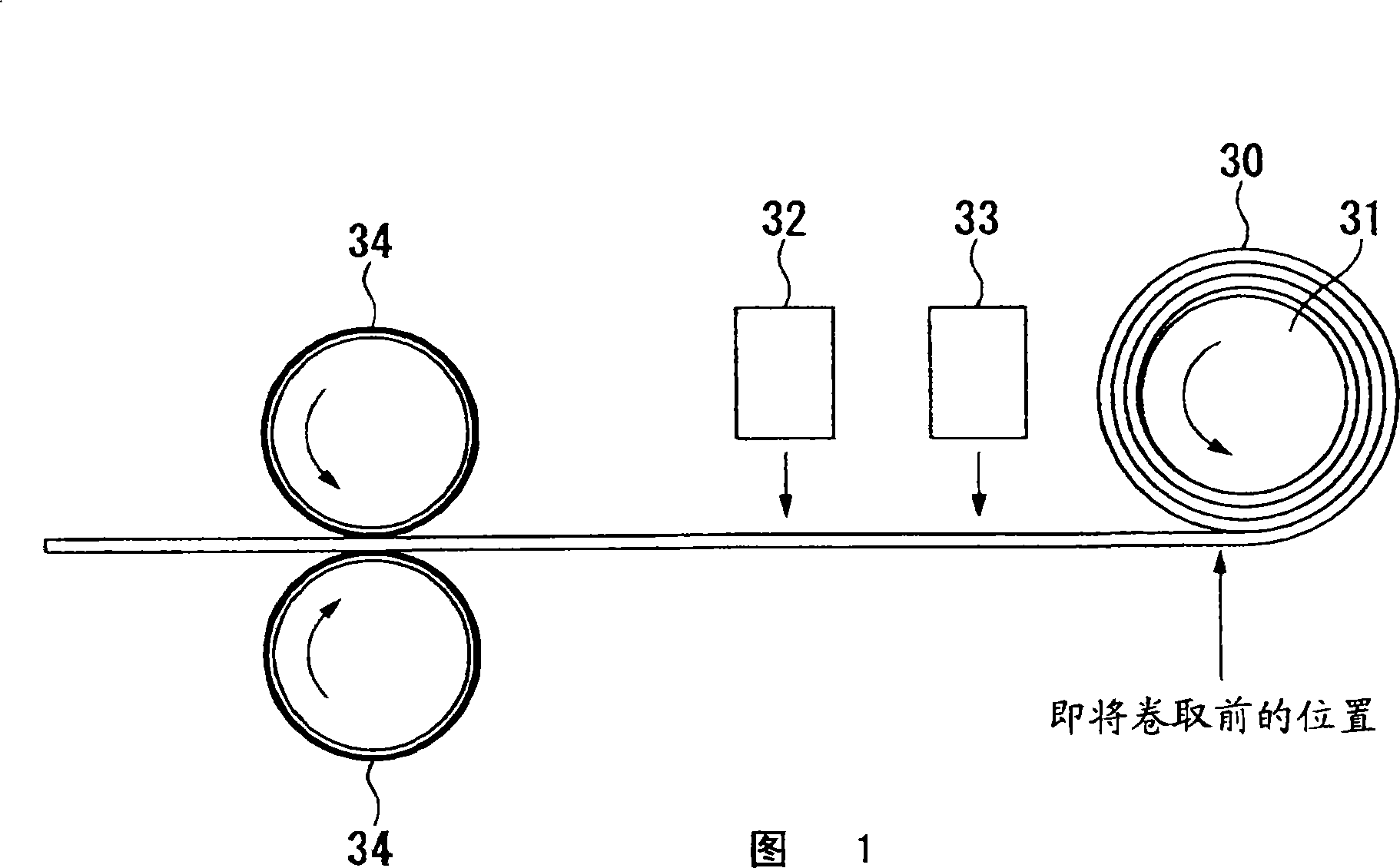

[0216] First, molten aluminum alloys obtained by melting aluminum alloys having respective compositional compositions are subjected to treatments such as processes for removing impurities by degassing and using a filter. Subsequently, the molten aluminum alloy was cast into a plate having a width of 1000 mm using a twin-roll continuous casting and rolling mill with a roll body diameter of 600 mm. During casting, the rate of solidification is controlled by the flow rate of water in the water-cooled roll 34 shown in FIG. 1 .

[0217] As shown in the schematic diagram of FIG. 1, an air-cooling fan (air-cooling fan) 32 and a mist supply unit 33 (mist su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com