Structural material piece of magnesium-containing silumin and method for preparing same

A high-silicon aluminum alloy and structural material technology, applied in the field of aluminum alloy and its preparation, can solve the problems of poor alloy deformation ability, high production cost and high process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The preparation of embodiment 1 semi-continuous casting billet

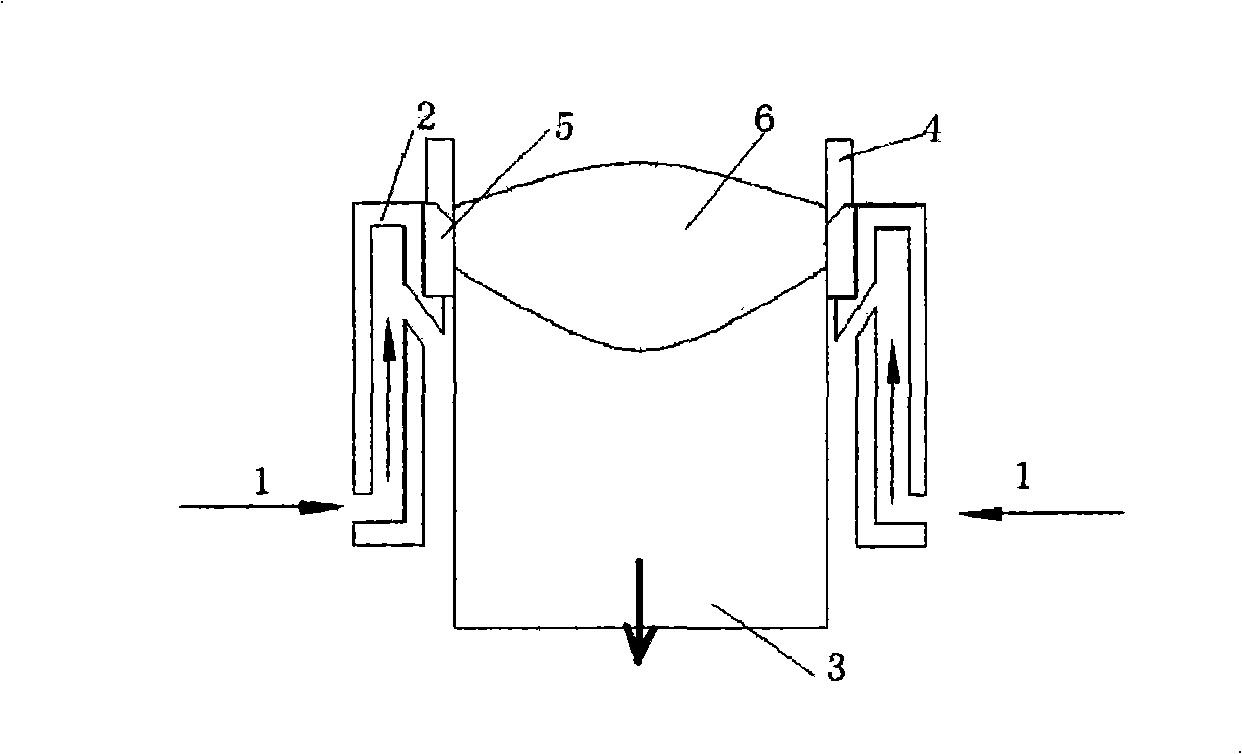

[0057] The selected equipment is self-made equipment, and its structural principle is shown in figure 1 . In the figure, 1-cooling water; 2-crystallizer; 3-blank; 4-hot top; 5-graphite ring, 6-metal liquid. The chemical composition of the alloy is shown in Table 2, and the casting process parameters are shown in Table 3.

[0058] Table 2 Chemical composition of semi-continuous casting magnesium-containing high-silicon aluminum alloys (wt.%)

[0059] Alloy

Si

Mg

Cu

Zn

Ni

Ti

Fe

Al

#1

8.5

0.7

0.5

0.3

0.3

0.27

Bal.

#2

8.5

1.8

0.27

Bal.

#3

12.7

0.7

0.3

Bal.

#4

12.7

1.2

1.5

0.3

0.3

0.3

0.3

Bal.

#5

15.5

0.7

0.27 ...

Embodiment 2

[0062] Pre-heat treatment and extrusion, rolling, forging of embodiment 2 cast alloy billet

[0063] The pre-heat treatment is heated in the heat treatment furnace according to the set heating rate, and after reaching the set temperature, it is kept for the set time. Plastic deformation is then done using extruders, hot rolling mills and forging machines. The specific process parameters are given in Table 4, Table 5 and Table 6 respectively.

[0064] Table 4 Pre-heat treatment and extrusion process parameters of different alloys

[0065] Alloy

preprocessing

heating rate

(℃ / min)

preprocessing

temperature

(℃)

preprocessing

time

(hr)

squeeze

temperature

(℃)

extrusion ratio

cool down

Way

After deformation

#1

25

450

3

450

36

nature

1A

#2

2...

Embodiment 3

[0070] Heat treatment after embodiment 3 alloy deformation (extrusion, rolling, forging)

[0071] The extruded, rolled, and forged workpieces are heat treated under the set heat treatment process parameters. The specific heat treatment process parameters are given in Table 7, Table 8, and Table 9, respectively. The mechanical properties of some alloys under different deformation modes and heat treatment states are given in Table 10.

[0072] Table 7 Heat treatment process parameters of different alloy extrusion products

[0073] After deformation

Alloy

Numbering

Alloy

Numbering

heat treatment

state

solid solution

temperature

(℃)

solid solution

time

(hr)

temperature

(℃)

time

(hr)

After heat treatment

Alloy

Numbering

1A

#1

T6

520

2

180

3

1AT6

3A

#3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com