High-strength 6xxx aluminum alloys and methods of making same

A technology of aluminum alloy and casting aluminum alloy, applied in the field of 6XXX aluminum alloy, can solve problems such as edge cracking and hot tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

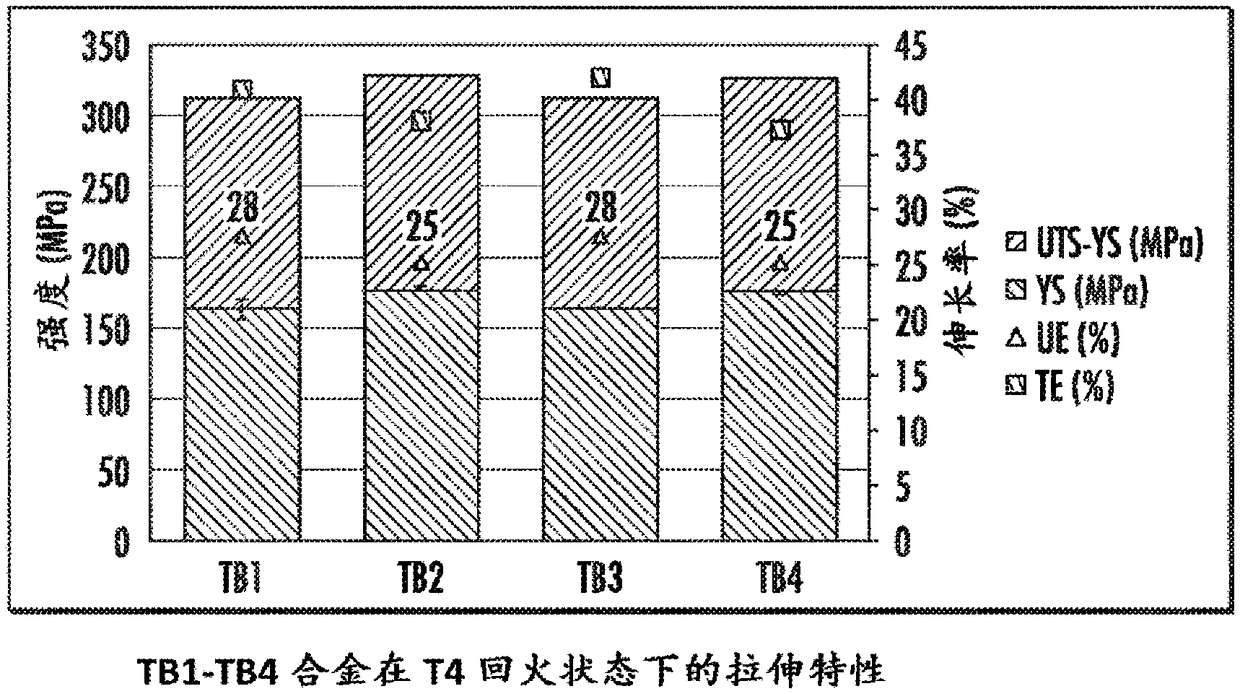

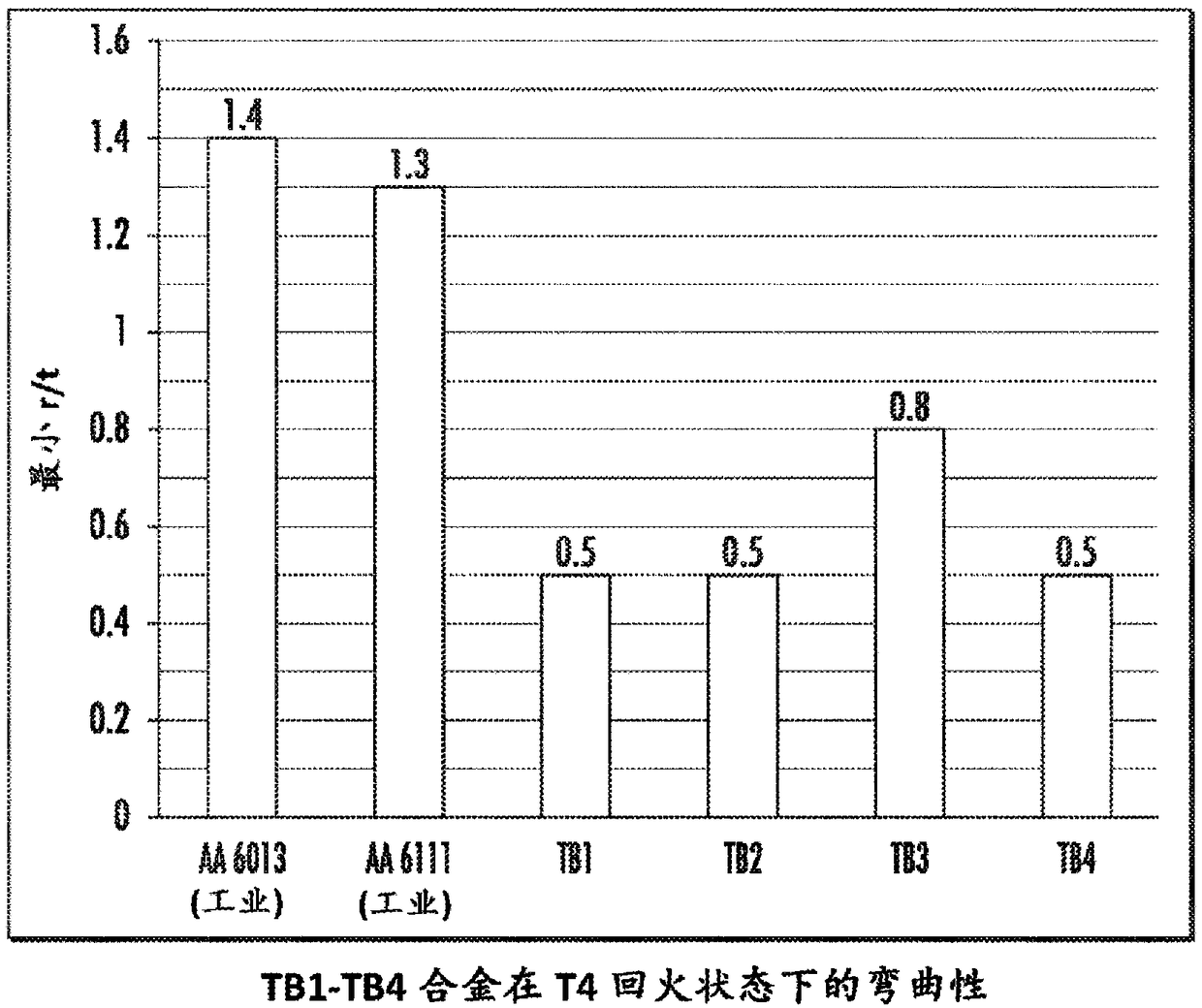

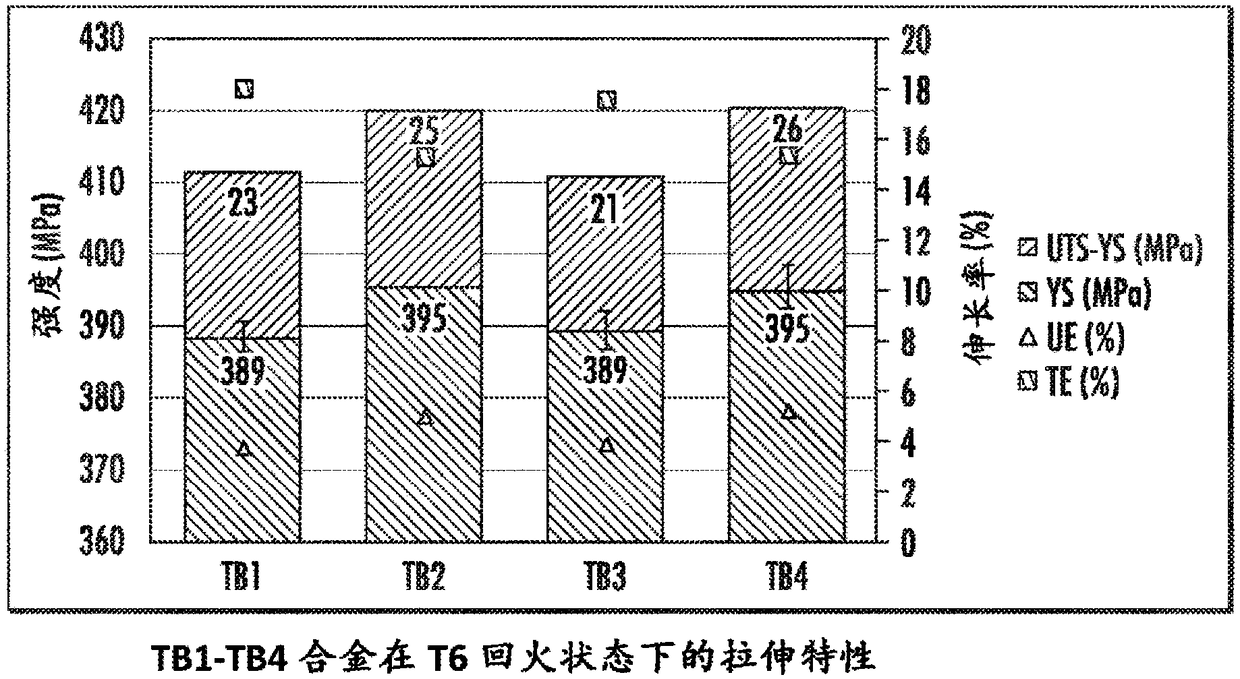

[0237] Example 1: Properties of Aluminum Alloys TB1, TB2, TB3, and TB4

[0238] A set of four exemplary aluminum alloys was prepared: TB1, TB2, TB3, and TB4 (Table 16).

[0239] Table 16: Composition of TB1-TB4 alloys (weight %)

[0240]

[0241]

[0242] The alloy was prepared by casting composition DC into an ingot and homogenizing the ingot at 520°C to 580°C for 1 hour to 5 hours. The homogenized ingot was then laid and hot rolled with an inlet temperature in the range of 500°C to 540°C and a hot roll outlet temperature in the range of 250°C to 380°C. A solution heat treatment step is then performed at 540°C to 580°C for 15 minutes to 2 hours, followed by room temperature quenching with water and natural aging to achieve the T4 temper. The T6 temper is achieved by aging the T4 alloy at 180°C to 225°C for 15 minutes to 8 hours.

[0243] The properties of the TB1-TB4 alloys were determined using testing procedures routine in the art and compared to control alloys AA6...

Embodiment 2

[0247] Example 2: Effect of Annealing

[0248] This example compares the properties of a TB1 alloy annealed in the T4 temper with a control TB1 alloy produced by a similar process without the annealing step.

[0249] The composition of the TB1 alloy is as described above in Table 16. Similar to Example 1, the initial processing for these two samples included conventional DC casting; homogenization at a heating rate of 10° / C-100° / C and soaking at a peak metal temperature of 520°C-580°C1 hours to 5 hours; and hot rolling, wherein the inlet temperature ranges from 500°C to 540°C and the hot roll outlet temperature ranges from 250°C to 380°C. Plate / sheet in the as-rolled condition is marked as being in the F temper.

[0250] For the control alloys, the plate / sheet in the F temper was then converted to the T4 temper by solutionizing at 540°C-580°C for a soaking time of 15 minutes to 2 hours, followed by water quenching and natural aging. The control was converted directly from t...

Embodiment 3

[0254] Example 3: Properties of aluminum alloys P7, P8, and P14 at different SHTs

[0255] A set of three exemplary aluminum alloys were prepared: P7, P8, and P14 (Table 18).

[0256] Table 18: Composition (weight %) of P7, P8, and P14 alloys

[0257] alloy

Cr

Cu

Fe

Mg

mn

Si

Zn

Ti

P7

0.03

0.66

0.16

1.16

0.17

1.19

0.005

0.02

P8

0.03

0.80

0.18

1.11

0.19

0.97

0.005

0.02

P14

0.03

0.61

0.18

1.20

0.18

1.09

0.004

0.02

[0258] Alloys were prepared according to the procedure of Example 1, except that the solution heat treatment soaking step was performed for a shorter time (45 seconds or 120 seconds).

[0259] The maximum elongation (in the T4 temper) and yield strength (in the T6 temper) of the P7, P8, and P14 alloys were determined using testing procedures routine in the art ( Image 6 ). Subsequent experiments were performed using different SHT c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com