High-strength aluminum alloy online quenching system and online quenching technology

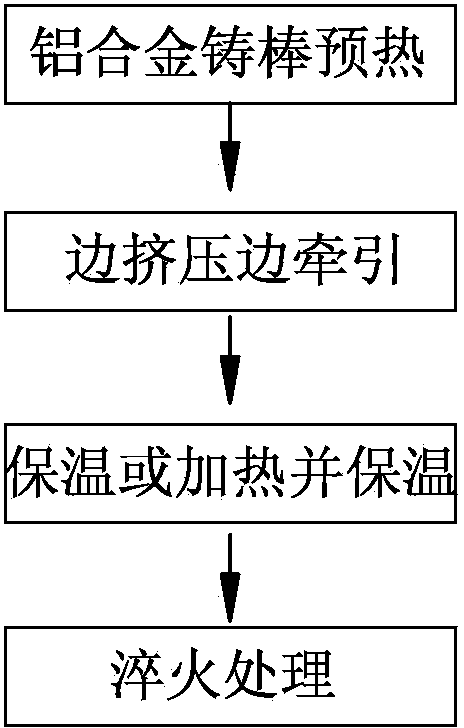

A technology of quenching system and aluminum alloy, which is applied in the field of online quenching process and high-strength aluminum alloy for online quenching system, which can solve the problems of high energy consumption, long production cycle and expensive investment of vertical air furnace in the quenching process, so as to avoid Heat loss and small deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further illustrated in a non-limiting manner below in conjunction with the accompanying drawings and examples.

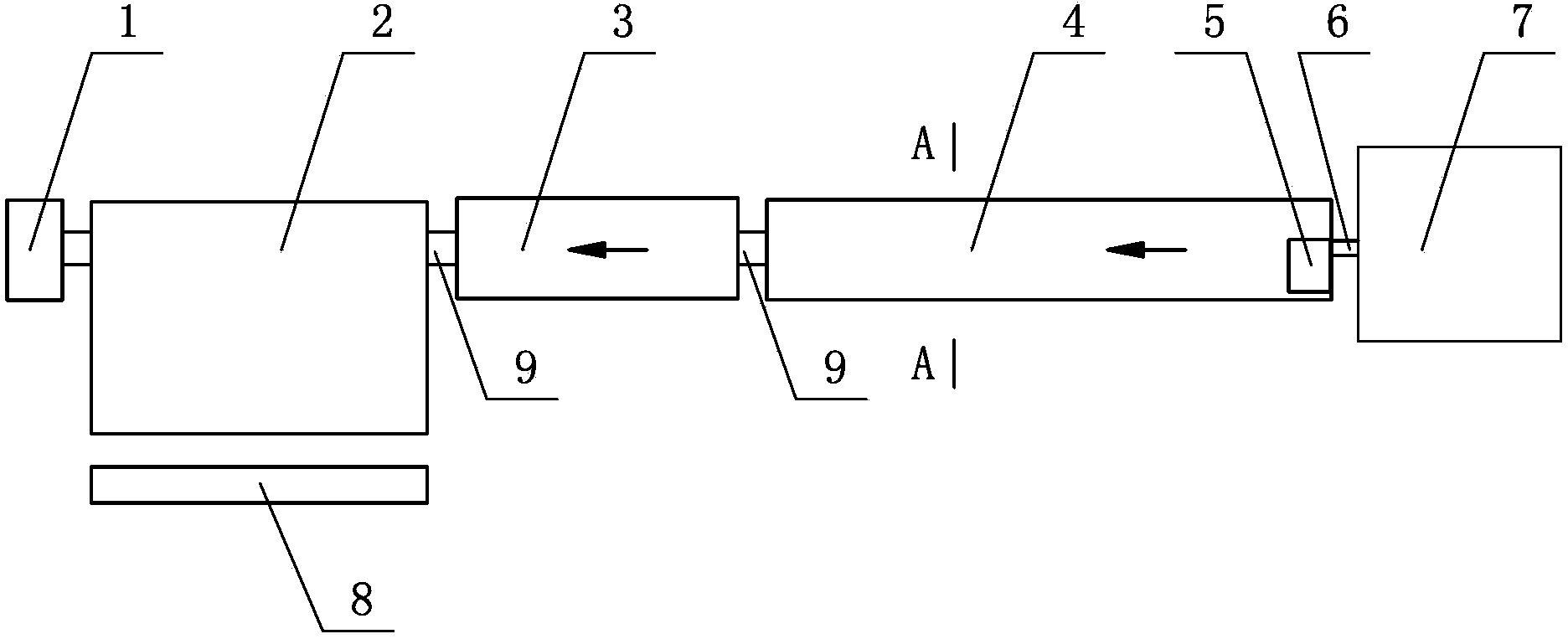

[0030] figure 1 The middle arrow shows the running direction of the aluminum alloy profile. Such as figure 1 As shown, the high-strength aluminum alloy online quenching system of the embodiment of the present invention includes:

[0031] Extruder 7, which is used to hot extrude the preheated aluminum alloy cast rod into aluminum alloy profiles;

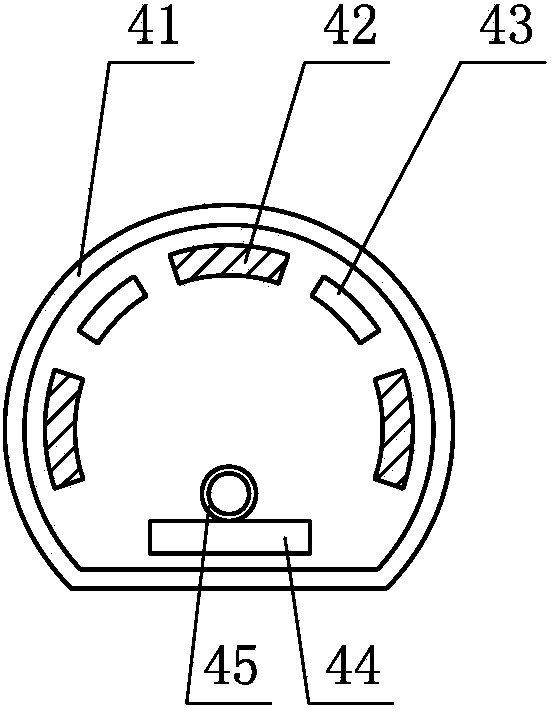

[0032] Holding furnace 4, holding furnace 4 is a horizontal cylindrical structure, wherein, the inlet of holding furnace 4 is set close to the profile outlet of extrusion machine 7, and holding furnace 4 is used to heat-extrude the aluminum alloy profile formed by extruder 7 keep warm, or heat and keep warm;

[0033] Quenching device 3, the quenching device 3 is arranged near the outlet of holding furnace 4, and is used for quenching the aluminum alloy profile extruded products from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com