High potential super capacitor electrode material and preparing method thereof

A technology for supercapacitors and electrode materials, applied in the field of materials and energy, can solve the problems of poor performance of supercapacitors, low working potential, low tap density, etc., and achieve the effects of improving performance, reducing energy consumption, and requiring less equipment

Inactive Publication Date: 2009-02-25

SICHUAN UNIV

View PDF0 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to overcome the current shortcomings of poor performance of supercapacitors due to low tap density and low working potential of carbon materials. Starting from the synthesis route and process, the supercapacitor can be improved by increasing the tap density and working potential of carbon materials. Capacitance and working potential of capacitors, thereby improving the energy characteristics and power characteristics of supercapacitors, and promoting the wide application of supercapacitors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

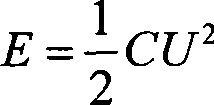

The invention relates to a high potential supercapacitor electrode material and a preparation method thereof, and belongs to the material and energy resource filed. The supercapacitor electrode material contains elements of C, Fe and P, the mass content of C is less than 10 percent, and other elements can be added as required. The working potential relative to LiLi can reach 4.3V and has good circulation stability. A matter containing C is added to a precursor, and the forming process of the material is utilized to synthesize and prepare the supercapacitor electrode material. The supercapacitor electrode material contains the elements of C, Fe and P, and can improve the compaction density of the C material and the working potential of the supercapacitor, thereby improving the capacity, the energy response and the power characteristics of the supercapacitor. Compared with the prior art, the method is convenient to operate, and the preparation process is simple and practical. The performance of the supercapacitor can be improved through the improvement of the compaction density and the working potential of the electrode material.

Description

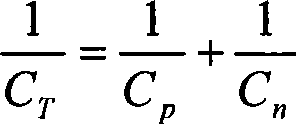

technical field The invention relates to a high-potential supercapacitor electrode material and a preparation method thereof, in particular to a preparation method of a supercapacitor electrode material containing C, Fe and P at the same time, and belongs to the field of materials and energy. Background technique Supercapacitors (Supercapacitors or Super Capacitors or Ultra Capacitors), also known as ultra-large capacity capacitors or electrochemical capacitors, commercial names are also known as (gold) capacitors (Gold Capacitors), energy storage capacitors or farad capacitors. With the breakthrough of material science and the development of electronic products, a new type of power electronic components has emerged and developed rapidly. It mainly includes electric double-layer capacitors and Faraday pseudo-capacitance capacitors. The two electrodes do not form a hybrid capacitor at the same time. In the energy diagram, it fills the gap between traditional capacitors and ba...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01G9/042H01G9/058H01G11/30H01G11/86

CPCY02E60/13

Inventor 王贵欣闫康平王飞刘睿李秀丽

Owner SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com