High abrasion-resistance polyurethane elastomer and preparation method thereof

A polyurethane elastomer, high wear-resistant technology, applied in the field of polyurethane products, can solve the problems of high price, achieve the effect of improving wear resistance, excellent wear resistance and mechanical properties, and improving dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

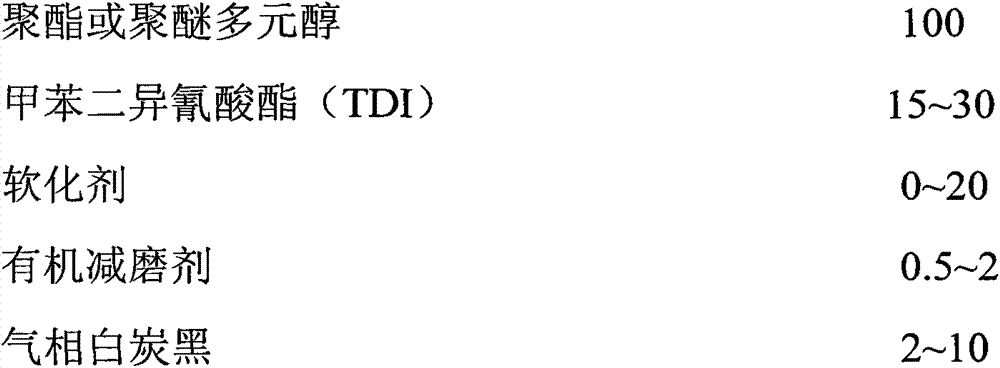

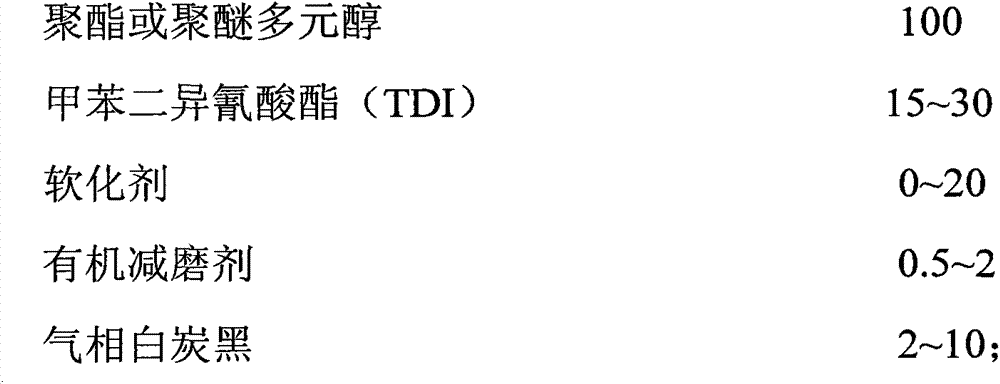

Method used

Image

Examples

Embodiment 1

[0026] Synthesis of component A: first mix 1000g polyester polyol LM2456, 100g DEP, 10g methyl silicone oil and 30g white carbon black, then put them into a ball mill for secondary mixing and dispersion, then take 585g into the reactor, heat to 125°C, vacuum After 2 hours of dehydration, the material temperature was lowered to 70°C, 220g of TDI was added, and the reaction was carried out at 75°C under nitrogen protection for 2h.

[0027] Preparation of component B: Melt MOCA and MCDEA respectively and mix them evenly in a molar ratio of 1:0.5.

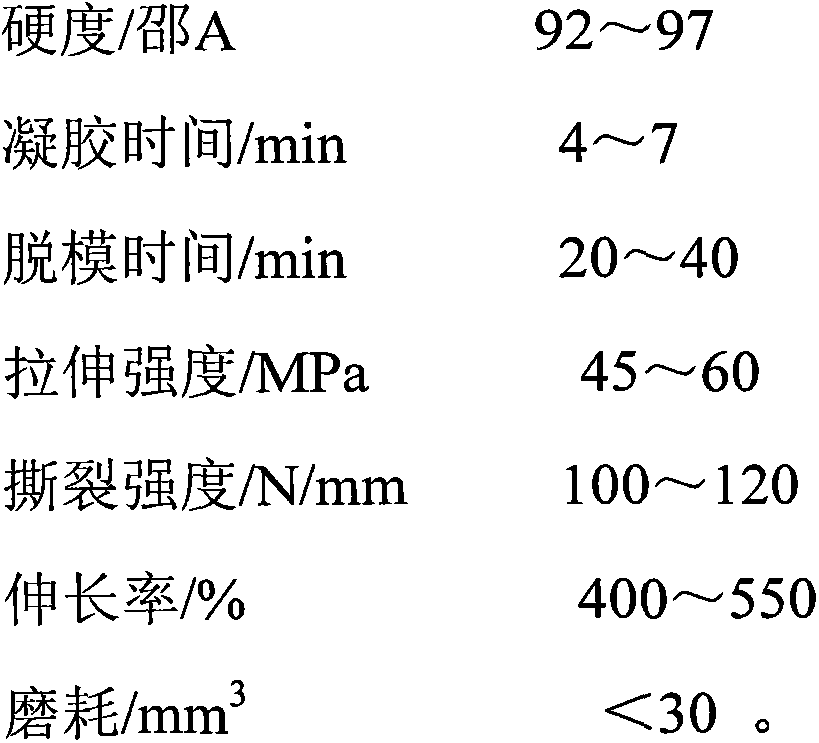

[0028] Preparation of elastomer: Mix and defoam components A and B according to the chain extension coefficient of 0.93, pour into a 2mm mold at 100°C, demould for 40 minutes, vulcanize at 125°C for 12 hours, and measure performance after 7 days at room temperature. The properties of the obtained materials are shown in Table 2.

Embodiment 2

[0030] Synthesis of component A: first mix 1000g of PTMG-1000, 20g of fluorocarbon emulsion and 60g of white carbon black, then put them into a ball mill for secondary mixing and dispersion, then take 510g into the reactor, heat to 120°C, and dehydrate under vacuum for 2 hours. Lower the material temperature to 70°C, add 242g of TDI, and react at 95°C for 1.5h under the protection of nitrogen.

[0031] Synthesis of component B: Melt MOCA and MCDEA respectively and mix them evenly in a molar ratio of 1:1.5.

[0032] Preparation of elastomer: After mixing and defoaming components A and B according to the chain extension coefficient of 0.9, pour it into a 2mm mold at 120°C, demould it for 20 minutes, vulcanize at 100°C for 16 hours, and measure its performance after standing at room temperature for 7 days. The properties of the obtained materials are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com