Production method for mixing rubber material at low temperature

A production method and rubber mixing technology, which is applied in the field of rubber tire production, can solve problems such as dispersion speed, low uniformity, high masterbatch discharge temperature, and long rubber mixing cycle, so as to improve quality and production efficiency , maintain high strength performance, improve the effect of tearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

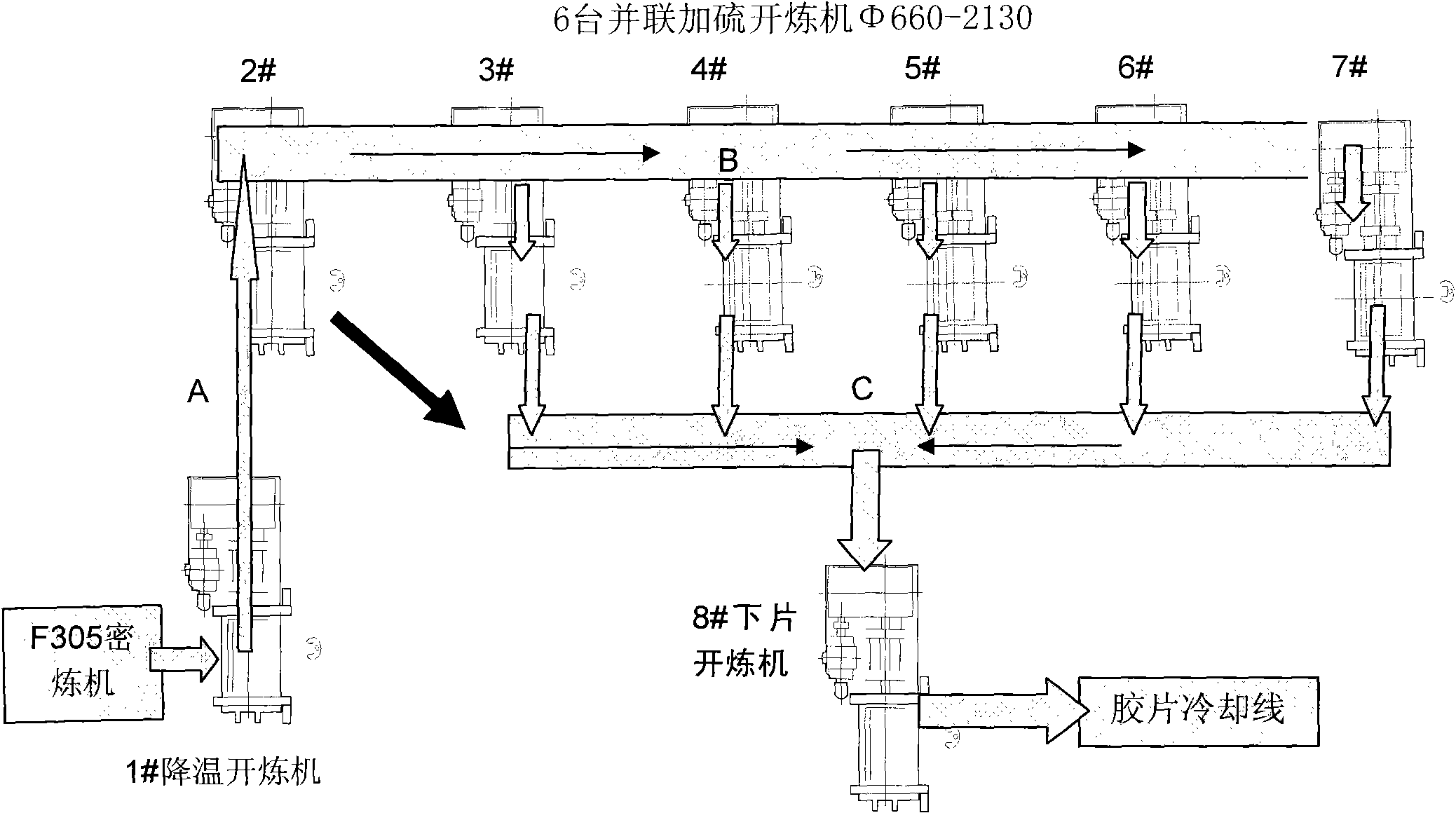

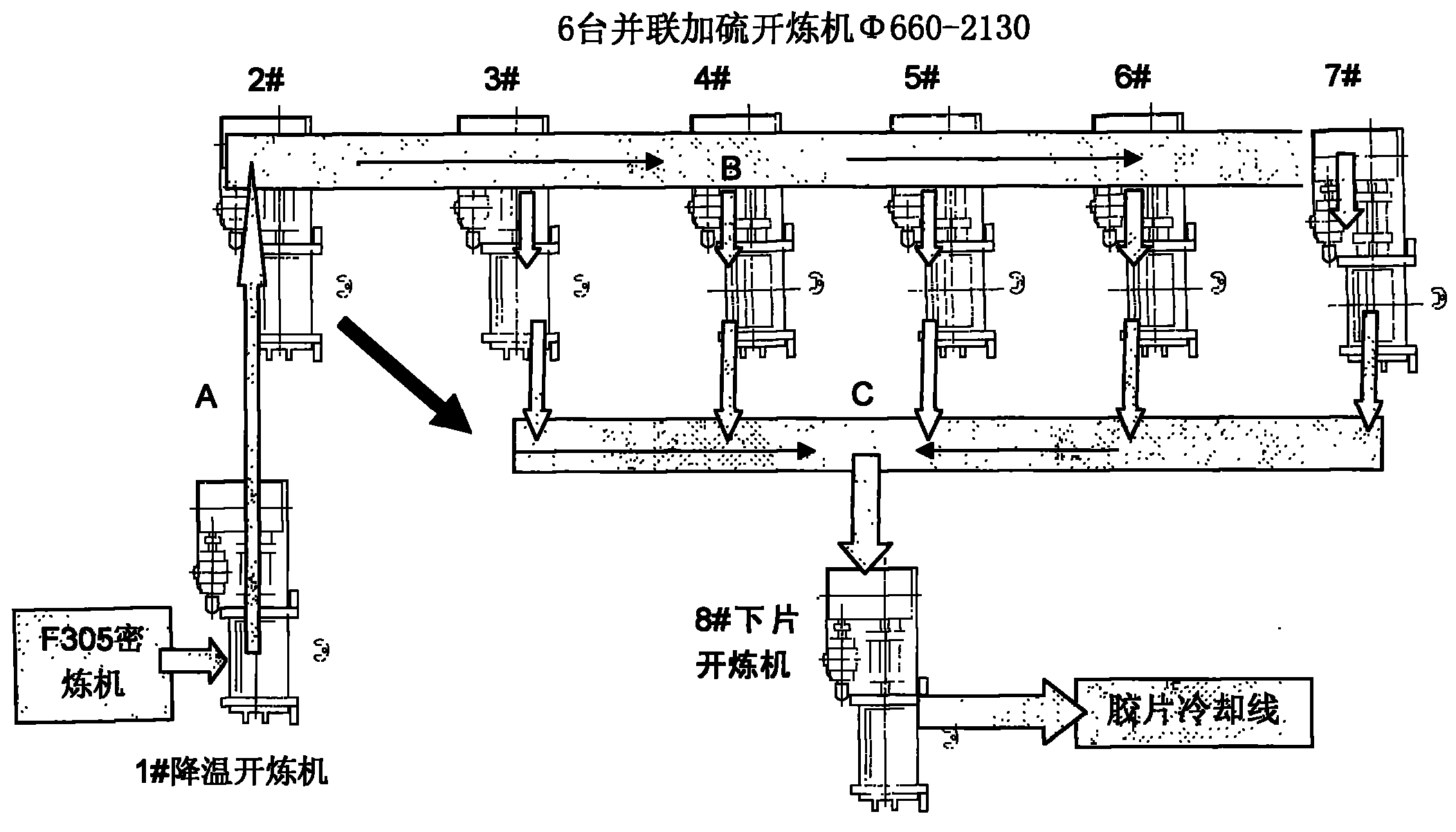

[0036] Example 1, such as figure 2 As shown, the production method of the low-temperature mixing rubber compound only has one internal mixer for low-temperature mixing and discharging, and is connected in turn below the internal mixer:

[0037] A 1# open mill for glue cooling and mixing,

[0038] 6 sets of 2# to 7# open mills connected in parallel for supplementary low-temperature mixing and vulcanization mixing,

[0039] An 8# open mill connected to the subsequent film cooling production line,

[0040] The rubber is fed and mixed in the internal mixer, and after reaching the temperature required by the process, it is discharged to the 1# open mixer for pounding and cooling, and then transported to the 2# open mixer in the open mixing unit through the conveying device for replenishment Mixing, the rubber material after supplementary mixing is transported to the 8# open mill for the next piece processing,

[0041] The 3# to 7# mills in the milling unit receive the rubber ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com