Screen deck and combined screen plate thereof

A technology of sieve plate and plate frame, applied in the field of sorting equipment, can solve the problems of low price, high cost of sieve plate, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

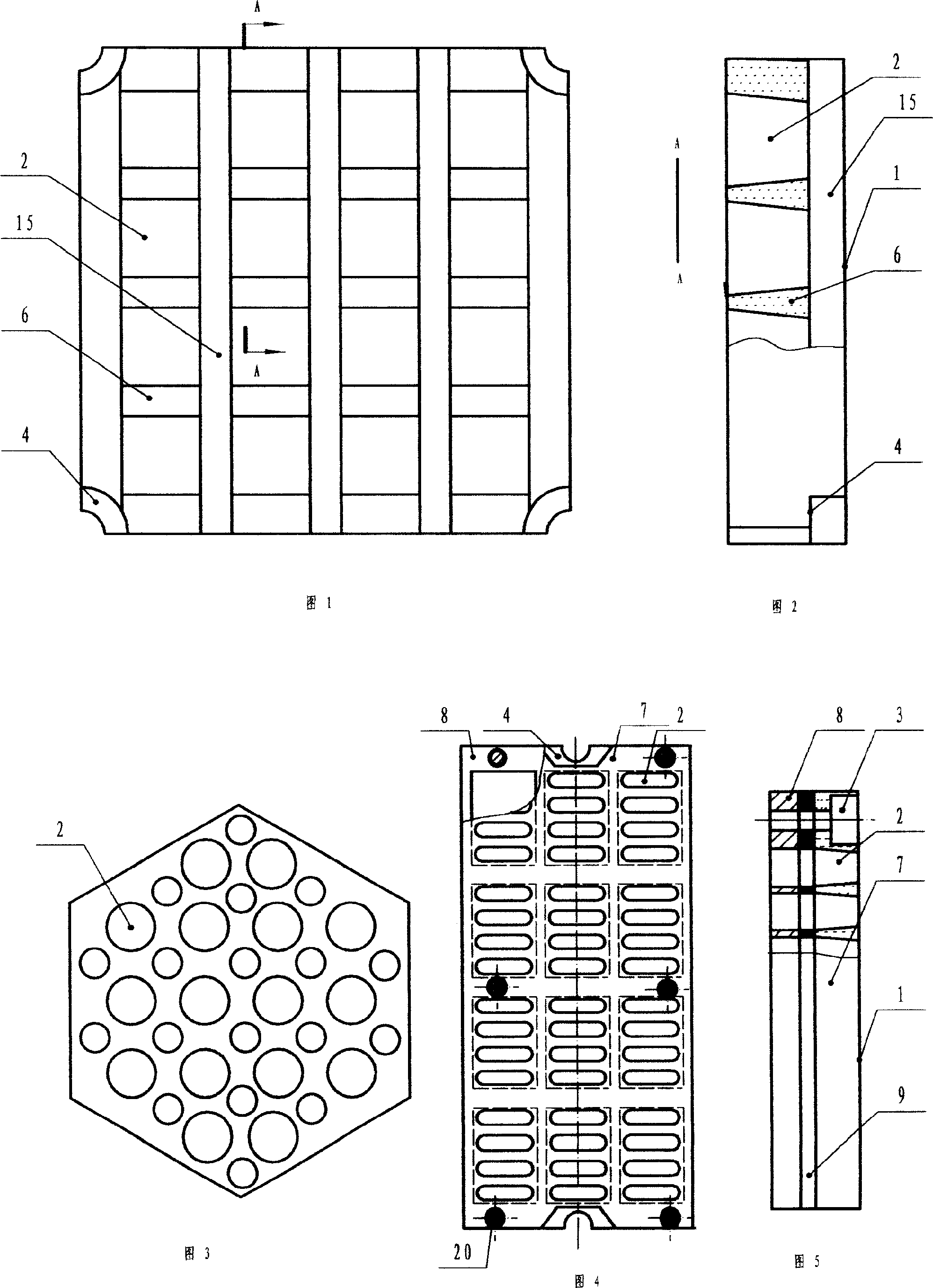

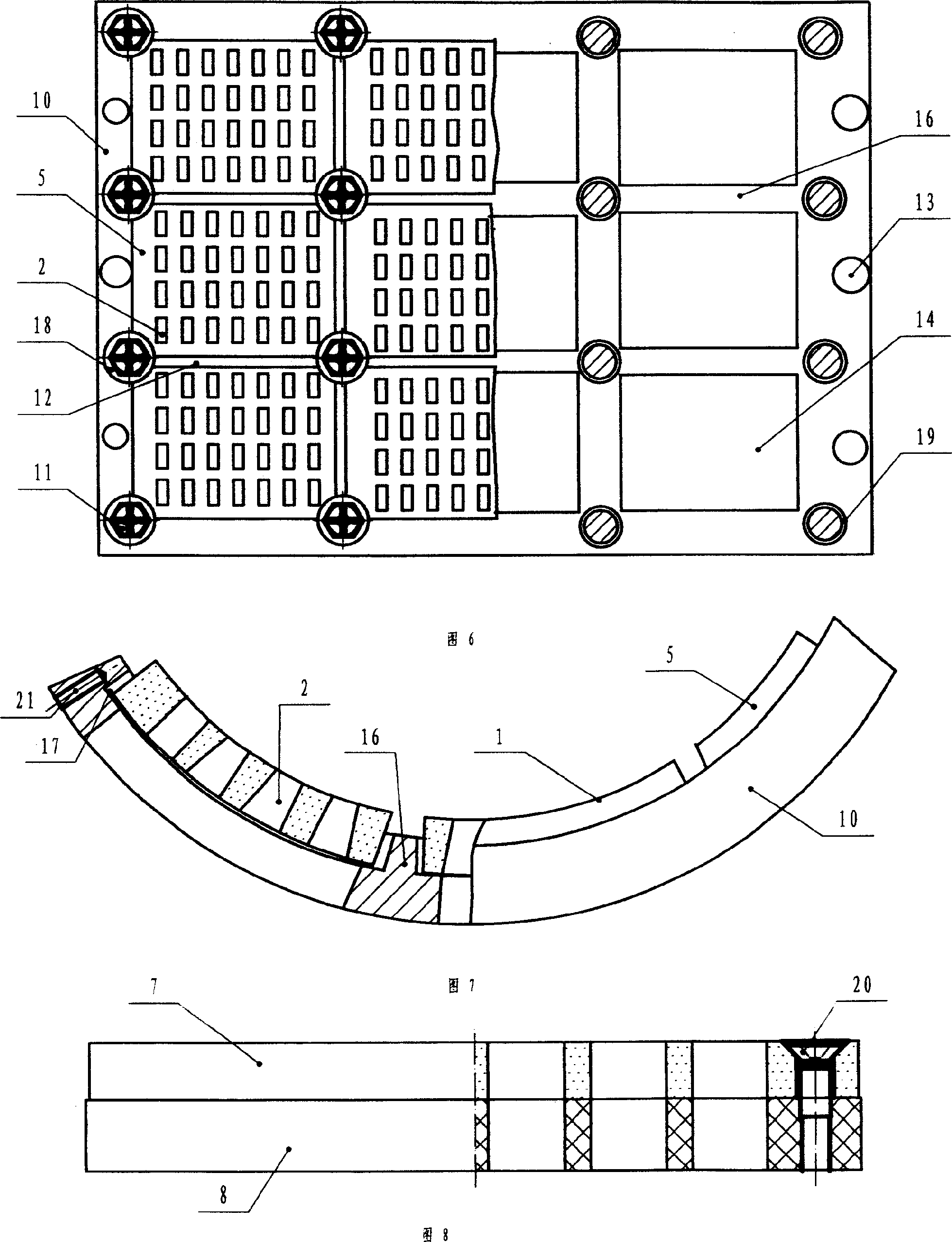

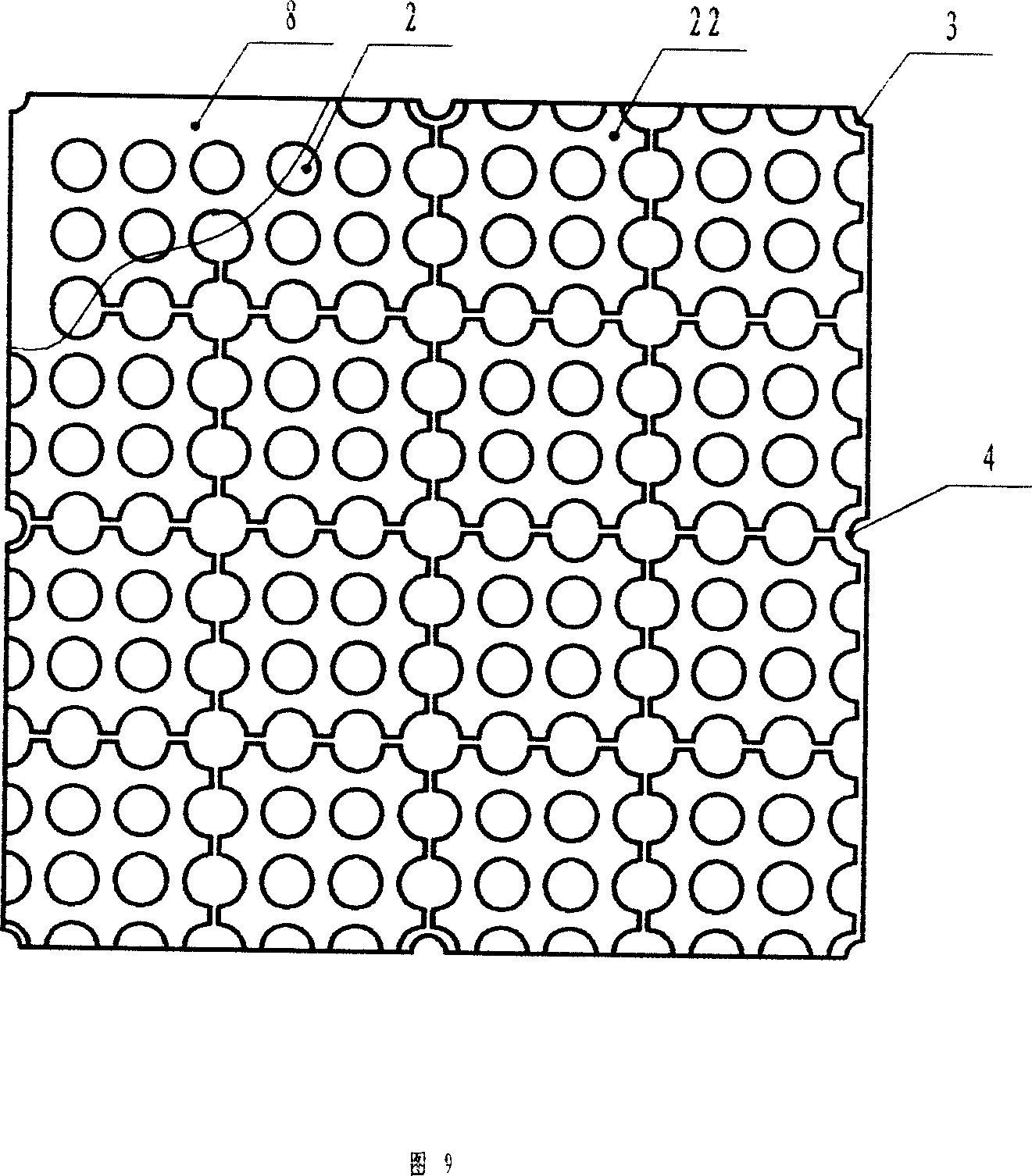

[0024] The sieve shown in Figure 1 is made of alumina ceramic material as a whole, which is made of 95% alumina powder, plus an appropriate amount of additives, and is molded and sintered. Silicon nitride ceramics, fused-cast chromium corundum ceramics, and zircon ceramics can also be used. , silicon carbide and silicon carbide fiber reinforced alumina and other materials are made of higher strength, more wear-resistant, more heat-resistant ceramic screen. The shape of the ceramic sieve is a square sheet, and the sieve surface is provided with 16 truncated pyramid-shaped sieve holes 2 of the same size arranged vertically and horizontally. Horizontal grid 6, establishes four installation press platforms 4 on four corners, and the end face of installation press platform 4 is the cambered surface that is compatible with compression bolt and washer. This structural sieve is suitable for installation on a flat combined sieve plate or directly on the bottom frame of the vibrating sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com