Artificial hip joint friction pair surface film layer and preparation method thereof

A technology of hip joints and friction pairs, which is applied in the field of metal surface film and its preparation, can solve problems such as implant failure, reduce the internal stress of the film, solve the wear of the joint head and socket, and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

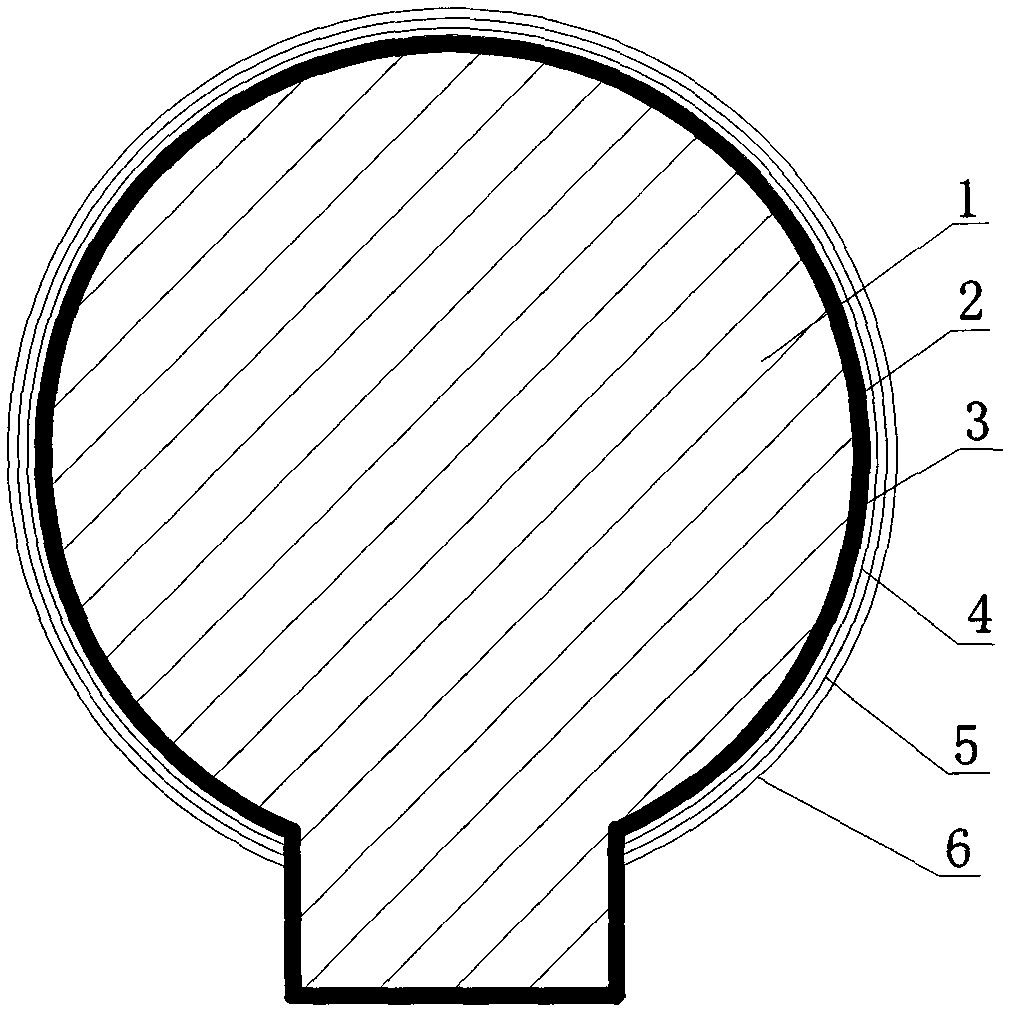

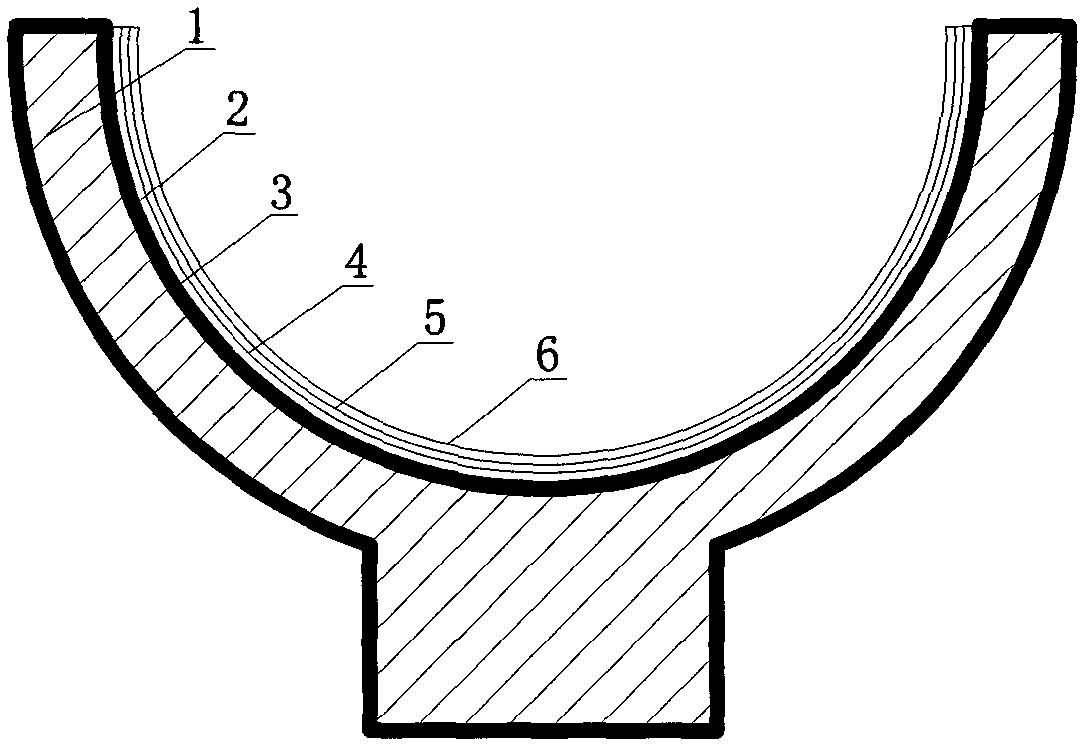

Image

Examples

Embodiment 1

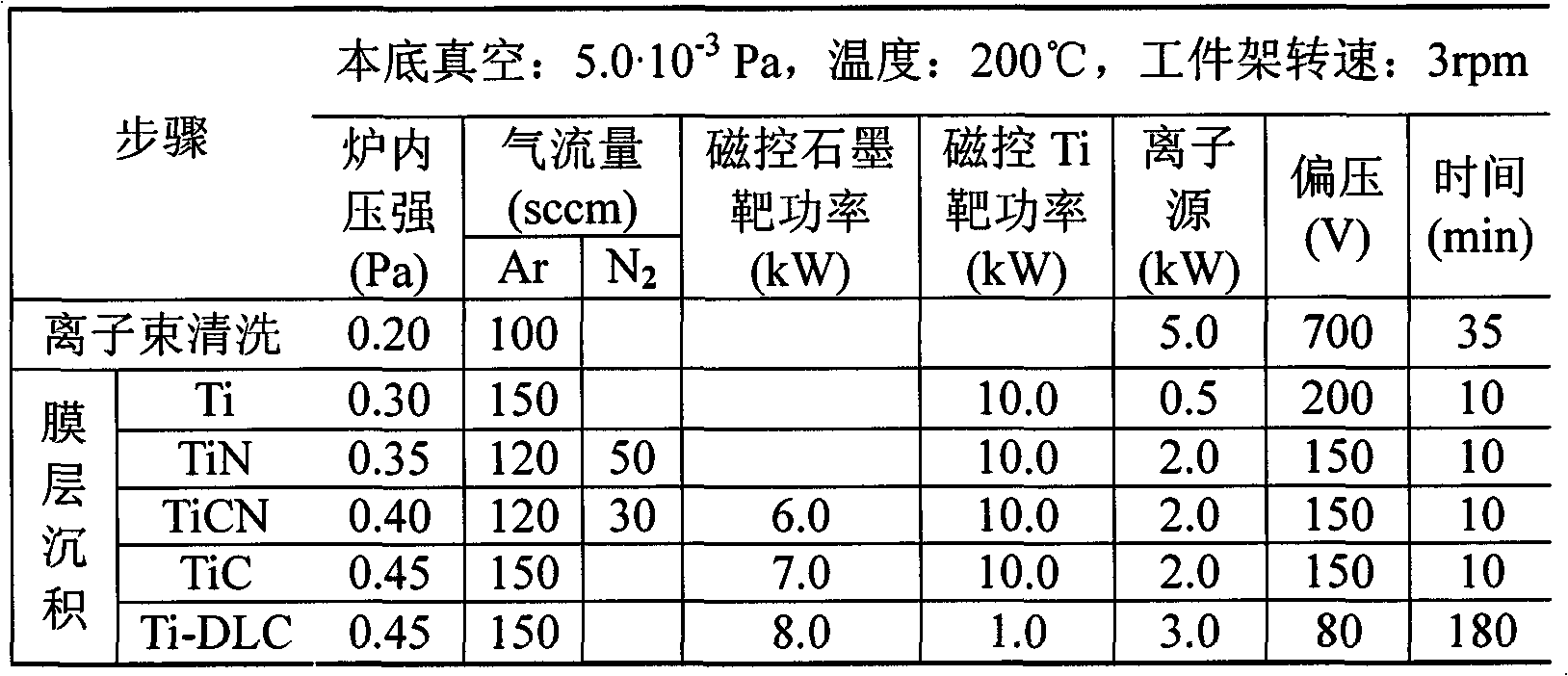

[0029] Table 1 Ti-DLC film process flow chart

[0030]

[0031] Ti targets are used, the gas is 99.99% argon and nitrogen, the ball head and acetabulum of the artificial hip joint are placed in a multi-functional ion coating machine, and Ti / TiN / TiCN / TiC / Ti-DLC layers are deposited in sequence, and the thicknesses are respectively 100nm, 200nm, 200nm, 200nm and 2000nm. The total thickness of the film layer is 2.7 μm. The surface color of the deposited artificial hip joint is uniform. The hardness value is Hv2300. 1.8×10 -19 m 3 / N·m.

Embodiment 2

[0033] Table 2 Cr-DLC film process flow chart

[0034]

[0035] Using a Cr target, the gas is 99.99% argon and nitrogen, and the artificial hip joint specimen is placed in a multifunctional ion coating machine, and Cr / CrN / CrCN / CrC / Cr-DLC layers are deposited in sequence, with thicknesses of 200nm, 300nm, and 300nm respectively. , 300mm and 3600nm. The total thickness of the film layer is 4.70 μm, the surface color of the deposited artificial hip joint is uniform, the hardness value is Hv2800, the bonding force of the film base is 72N, the dry friction coefficient of Cr-DLC to Cr-DLC is 0.09, and the measured average wear rate 4.4×10 -20 m 3 / N·m.

Embodiment 3

[0037] Table 3 Ta-DLC film process flow chart

[0038]

[0039] Using Cr and Ta targets, the gas is 99.99% argon and 99.9% nitrogen, and the artificial hip joint specimen is placed in a multifunctional ion coating machine to deposit Cr / CrN / CrCN / CrC / Ta-DLC multilayer films in sequence, with different thicknesses. 100nm, 200nm, 200nm, 200nm and 1500nm. The total thickness of the film layer is 2.30 μm. The surface color of the deposited artificial hip joint is uniform. The hardness value is Hv2500. 1.2×10 -19 m 3 / N·m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com