Super-tough polyamide alloy as well as preparation method and application thereof

A technology of tough polyamide and polyamide, which is applied in the field of super tough polyamide alloy and its preparation, can solve the problems of limited application and poor impact performance of polyamide, and achieve good dimensional stability, low moisture absorption, and high notch impact intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

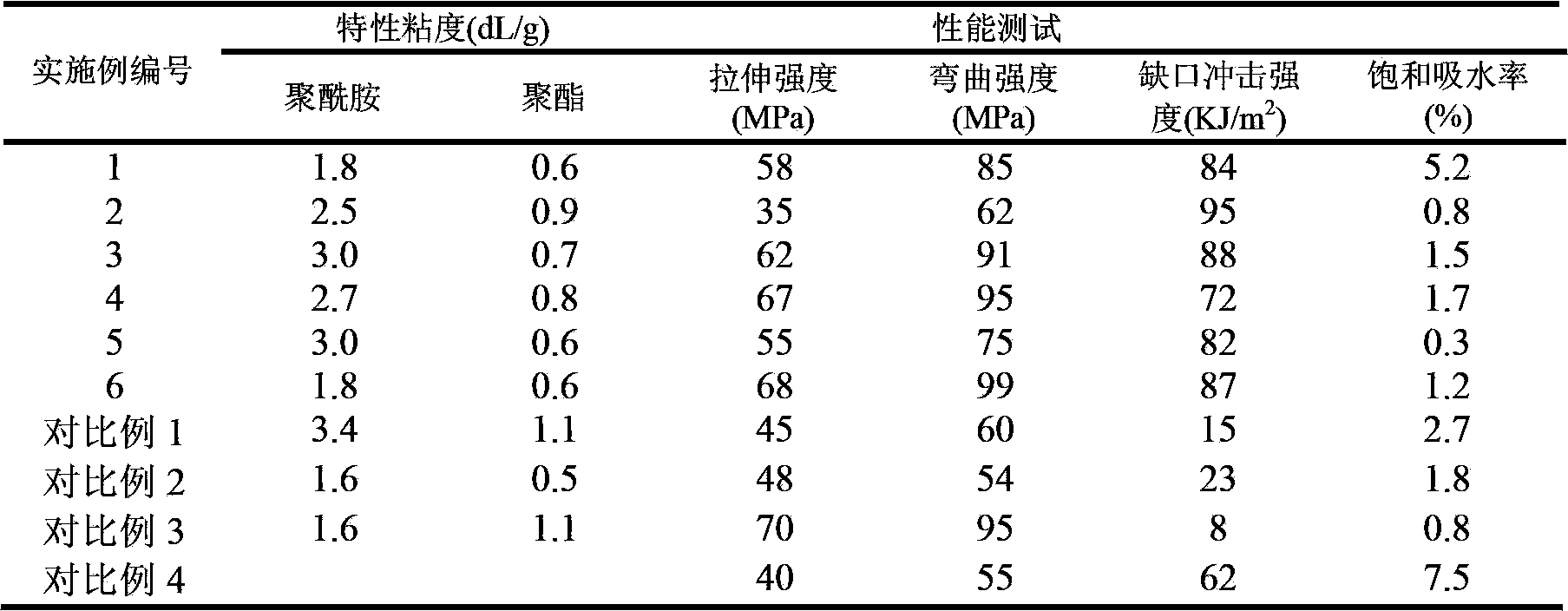

Examples

Embodiment 1

[0037] A super-tough polyamide alloy prepared by the following method:

[0038] (1) Vacuum dry PA6 and PET at 120°C for 4 hours;

[0039] (2) Take 81.5% PA6 (viscosity 1.8dL / g), 2% PET (viscosity 0.6dL / g), 0.5% sodium benzenesulfonate, 10.5% maleic anhydride grafted ethylene-octene Copolymer, 4.5% SEBS, 1% processing aids (0.5% nucleating agent superfine talc, 0.25% antioxidant 1098 and 0.25% lubricant polyethylene wax; the same below). After mixing with a high-speed mixer, it is weighed by weight loss and added to an extruder to extrude and granulate to obtain a super-tough polyamide alloy; the stated percentages are the percentages of each component in the total mass of raw materials.

[0040] The settings of the twin-screw extruder are as follows: the temperature of the first zone of the twin-screw extruder is 120~140°C, the temperature of the second zone is 260~270°C, the temperature of the third zone is 240~250°C, the temperature of the fourth zone is 240~250°C, and the ...

Embodiment 2

[0042] A super-tough polyamide alloy prepared by the following method:

[0043] (1) Vacuum dry PA12 and PBT at 120°C for 4 hours;

[0044] (2) Take 40% PA12 (viscosity 2.5dL / g), 25% PBT (viscosity 0.9dL / g), 2% potassium benzenesulfonate, 2% maleic anhydride grafted polyethylene, 30 % of maleic anhydride grafted EPDM rubber and 1% of processing aids are mixed with a high-speed mixer and added to the extruder by weight loss metering to extrude and granulate to obtain super-tough polyamide alloy; The percentages are the percentages of each component in the total mass of raw materials.

[0045] The settings of the twin-screw extruder are as follows: the temperature of the first zone of the twin-screw extruder is 120~140°C, the temperature of the second zone is 260~270°C, the temperature of the third zone is 240~250°C, the temperature of the fourth zone is 240~250°C, and the temperature of the fifth zone The temperature is 240~250°C, the temperature in the six zones is 240~250°C,...

Embodiment 3

[0047] A super-tough polyamide alloy prepared by the following method:

[0048] (1) Vacuum dry PA66 and PET at 120°C for 4 hours;

[0049] (2) Take 36% PA66 (viscosity 3.0dL / g), 36% PET (viscosity 0.7dL / g), 3% polyester ionomer (DuPont SURLYN 9320), 24% Malay Anhydride grafted ethylene-octene copolymer and 1% processing aid are mixed with a high-speed mixer and added to the extruder to extrude and granulate by weight loss metering to obtain a super-tough polyamide alloy; the percentage is The percentage of each ingredient in the total mass of raw materials.

[0050] The settings of the twin-screw extruder are as follows: the temperature of the first zone of the twin-screw extruder is 120~140°C, the temperature of the second zone is 260~270°C, the temperature of the third zone is 240~250°C, the temperature of the fourth zone is 240~250°C, and the temperature of the fifth zone The temperature is 240~250°C, the temperature in the six zones is 240~250°C, the temperature of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com