Building sealing strip based on thermoplastic ethylene-propylene-diene monomer (EPDM) rubber material and preparation method of building sealing strip

A technology of EPDM rubber and sealing strip, applied in the field of building sealing strip and its preparation, can solve the problems of heat resistance, environmental pollution, and no thermoplastic resin thermoplastic processing performance, and can meet the requirements of size and performance, Reduce energy consumption and environmental pollution, and ensure the effect of preparation consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

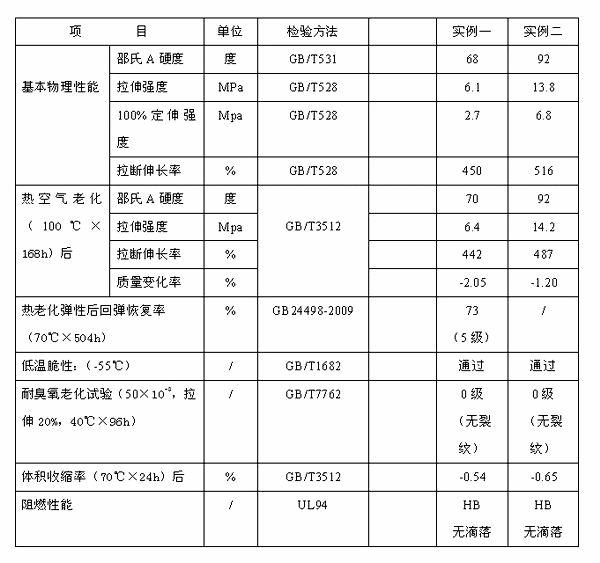

Examples

preparation example Construction

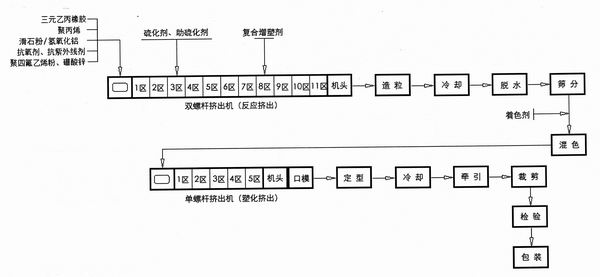

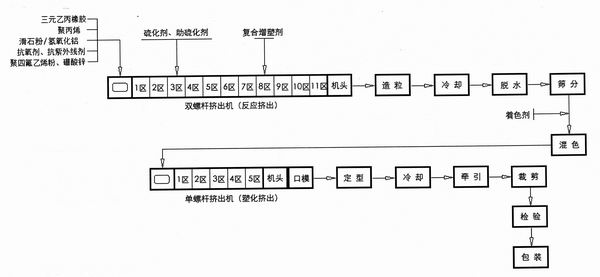

[0073] The preparation method of the building sealing strip based on thermoplastic EPDM material of the present invention comprises steps as follows:

[0074] 1) Weighing raw materials: Weigh raw materials according to the determined weight parts, take 30-50 parts of EPDM rubber, 15-40 parts of polypropylene, 2-10 parts of naphthenic rubber oil, 2-10 parts of paraffin oil, phosphoric acid 5-20 parts of ester, 2-10 parts of talcum powder, 5-20 parts of aluminum hydroxide, 0.2-1 part of antioxidant, 0.2-1 part of anti-ultraviolet agent, 0.5-2 parts of vulcanizing agent, 1-5 parts of auxiliary vulcanizing agent 5-10 parts of zinc borate, 2-5 parts of polytetrafluoroethylene powder, 0.5-5 parts of colorant;

[0075] 2) Mixing: Mix and knead EPDM rubber, polypropylene, talcum powder, aluminum hydroxide, antioxidant, anti-ultraviolet agent, zinc borate and polytetrafluoroethylene powder in a stirring pot evenly, room temperature, time 2 minutes, release the mixed material; mix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com