Silicon resin filled EPDM heat insulation material

A technology of thermal insulation material and silicone resin, which is applied in the field of rubber compound to achieve the effect of improving the ability to scour external stress, excellent ablation resistance, and hard and dense carbon layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

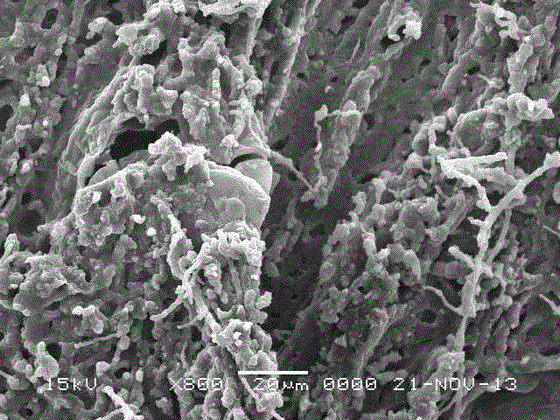

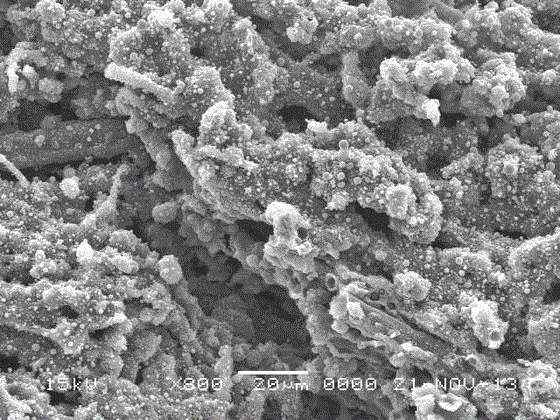

Image

Examples

Embodiment 1- Embodiment 5

[0039] The formula of table 1 embodiment 1-embodiment 5 and material kind *

[0040]

[0041] SR-1 is phenyl silicone rubber with grade 120-1; SR-2 is a phenyl silicone resin; SR-3 is a methyl silicone resin;

[0042] SR-4 is a cage-type silsesquioxane silicone resin.

[0043] (1) stocking: stocking according to the proportioning of each embodiment in table 1;

[0044] Description: The total number of fillers in Example 2-Example 5 is 169phr, respectively: EPDM, 100.0; ZnO, 3.0; SA, 1.0; vulcanizing agent, 3.0; surfactant, 3.0; tackifying resin, 10.0; Fiber, 8.0; Carbon Black (C), 5.0; SiO 2 , 10.0; smoke suppressant (MoO 3 ), 3.0; MMg, 3.0; silicone, 20.0. Embodiment 1 does not add silicone resin, and the total number of parts of material is 149phr.

[0045] (2) Mixing and sample preparation: operate according to the mixing and vulcanization process of the conventional thermal insulation layer.

[0046] (3) Performance test: Test the performance of the insulation ma...

Embodiment 6- Embodiment 9

[0052] The formula of table 3 embodiment 6-embodiment 9

[0053] (1)

[0054] (2) stocking: stocking according to the proportioning of each embodiment in table 3;

[0055] The common basic formula of embodiment 6-embodiment 9 selects the material and proportion of embodiment 1, namely: EPDM, 100.0; ZnO, 3.0; SA, 1.0; DCP, 3.0; WD-70, 3.0; TR, 10.0; PA , 8.0; carbon black (C), 5.0; SiO 2 , 10.0; smoke suppressant (MoO 3 ), 3.0; MMg, 3.0, a total of 149phr.

[0056] (3) Mixing and sample preparation: operate according to the mixing and vulcanization process of the conventional heat insulation layer.

[0057] (4) Performance test: Test the performance of the insulation material according to the corresponding standard specifications, and the specific results are shown in Table 4.

[0058] Example 6-Example 9 adjusted the amount of two silicone resins, SR-2 and SR-4, and added an appropriate amount of magnesium salt (MMg). From the results in Table 5, it can be seen that wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com