Preparation method of high-gloss high-rigidity no-precipitate environment-friendly flame-retardant polypropylene

A flame-retardant polypropylene, high-rigidity technology, applied in the field of high gloss, can solve the problems of large amount of addition, easy decomposition of flame retardants, difficult processing, etc., and achieve good flame retardancy, good processing performance, and good heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

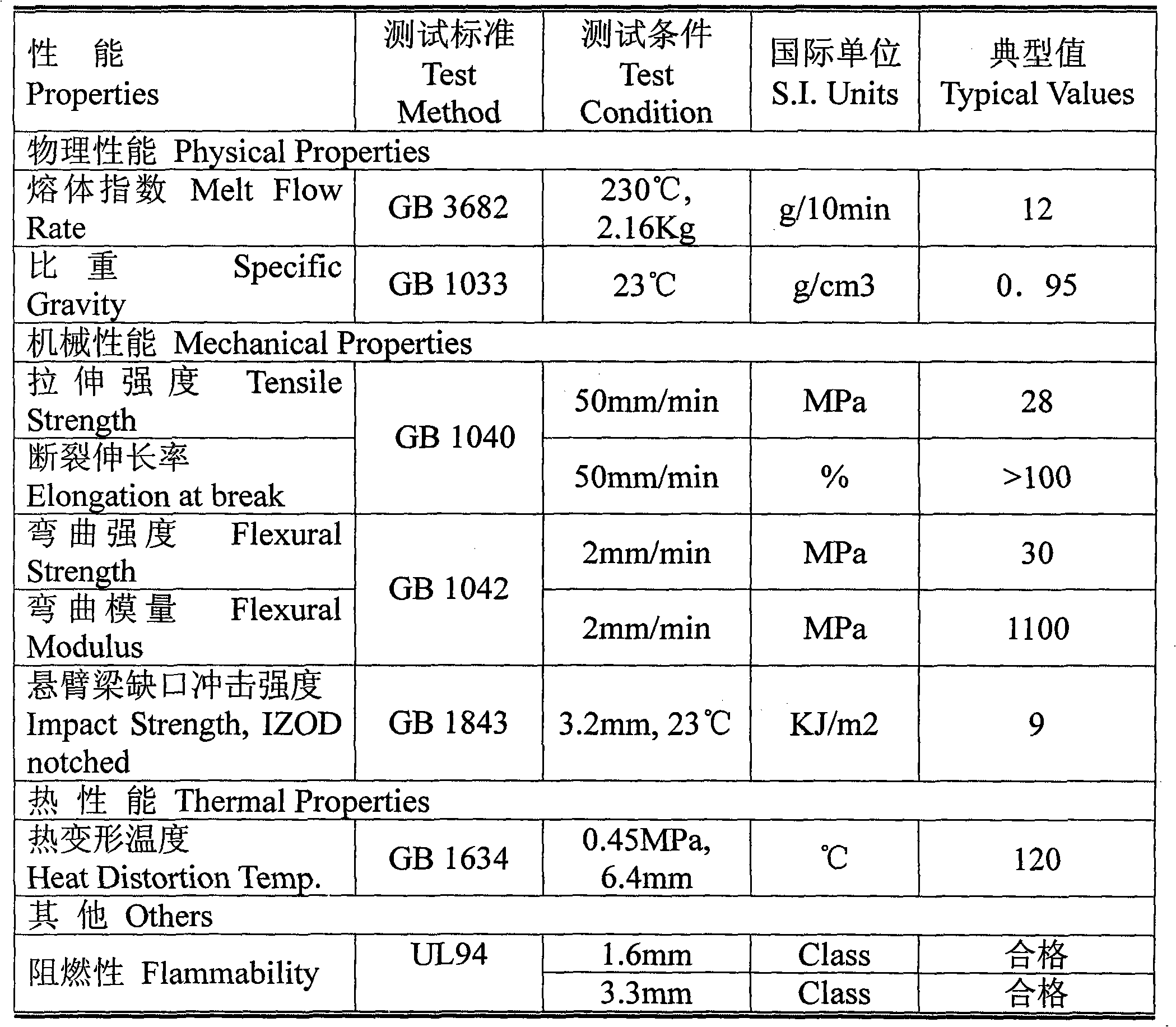

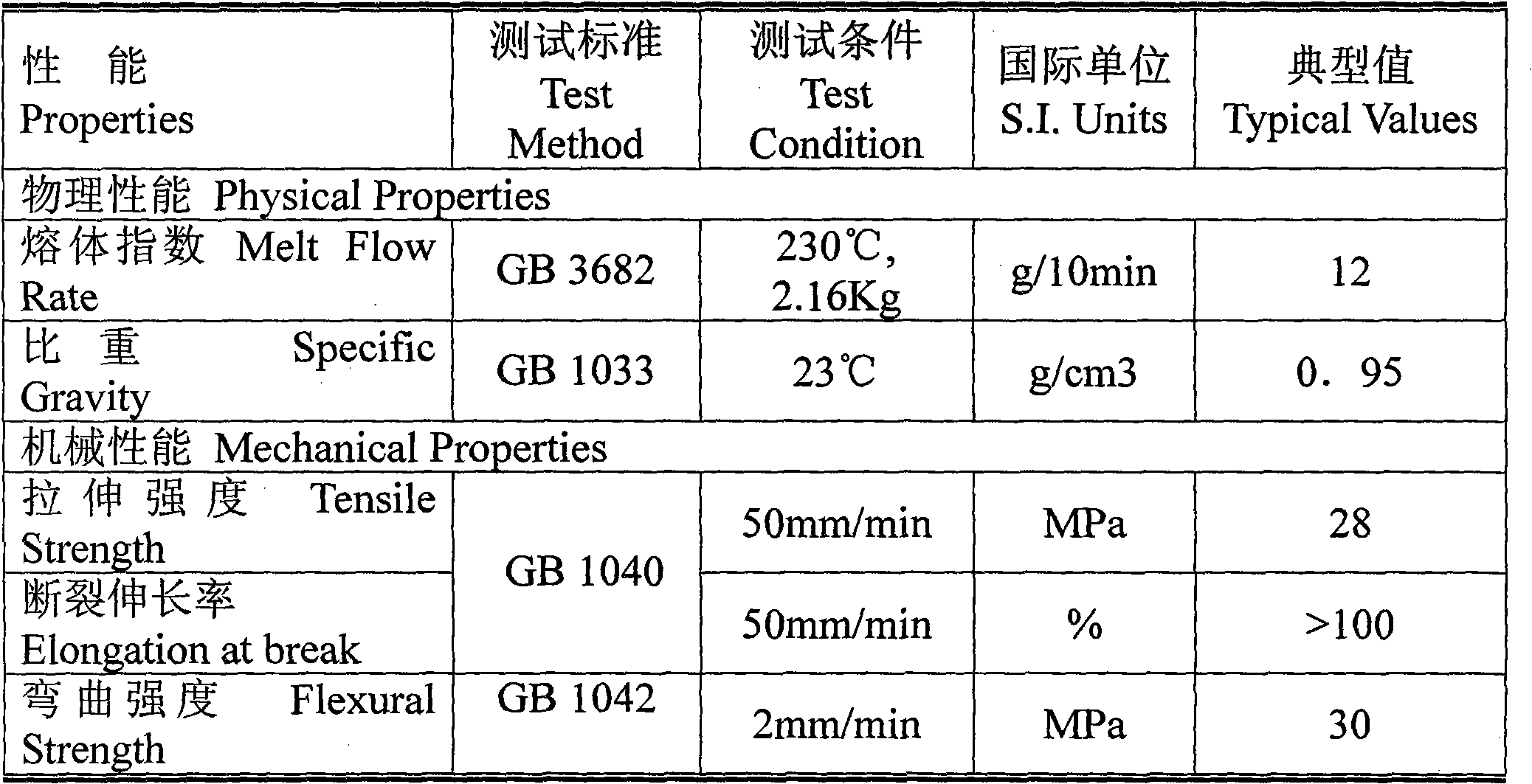

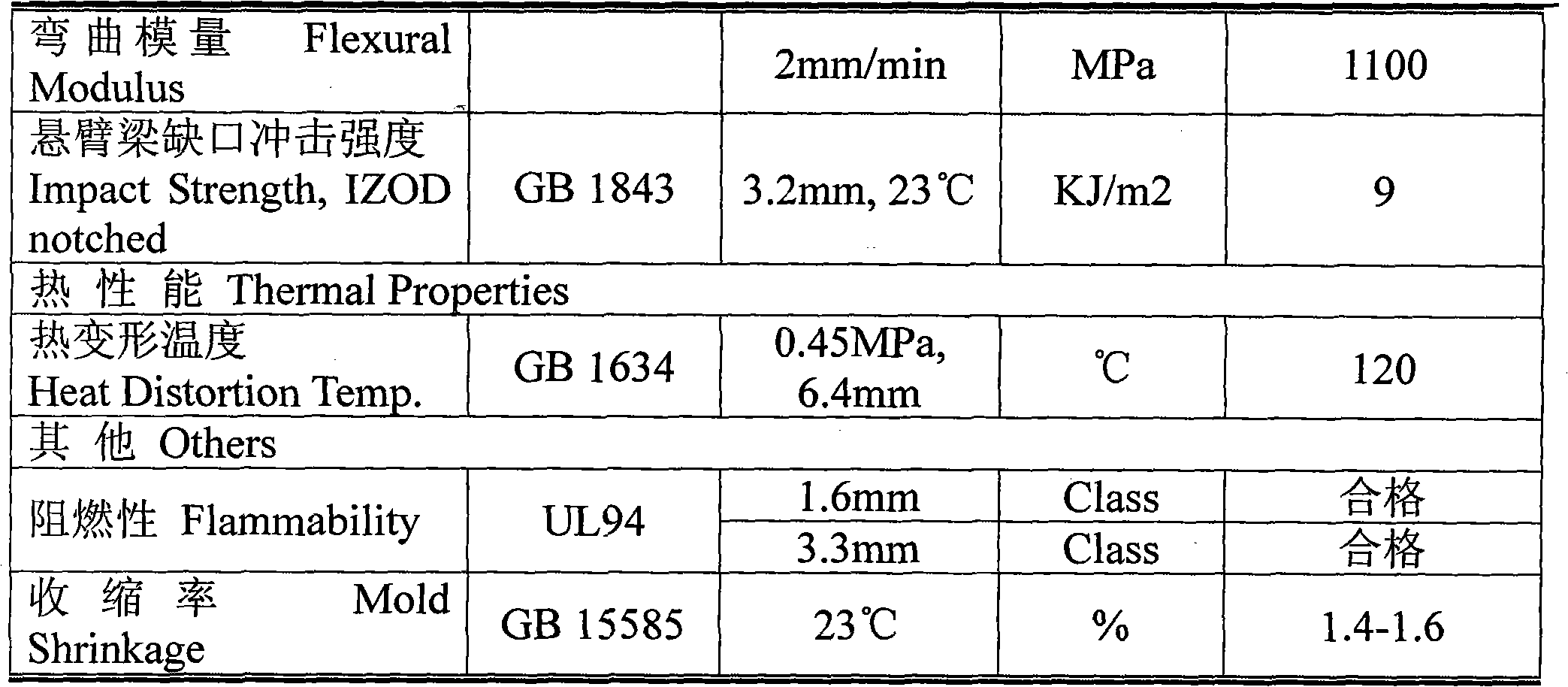

[0020] 45kgPPV30G, 45kgPP370Y, 4kg octabromoether flame retardant, 2kg antimony trioxide, grafted PP3kg, 8kgEVA, 0.3KG calcium stearate, 0.2kg PE wax, 0.2kg of 1010 / 168 in a 1:2 mixture, 0.3kg of white oil is mixed evenly in a high-speed mixer, and then extruded, cooled, pelletized, and made of flame-retardant polypropylene with a twin-screw extruder at a speed of 350-400 rpm and 180-200°C, and then molded. The spline properties are as follows:

[0021]

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com