Double-layer metal cladded flame-retardant electric cable

A wire and cable, double-layer metal technology, applied in the field of electrical products, can solve problems such as high cost, obstructing sight, and weak conductivity, and achieve the effects of reducing material costs, reducing accidental losses, and less smoke generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

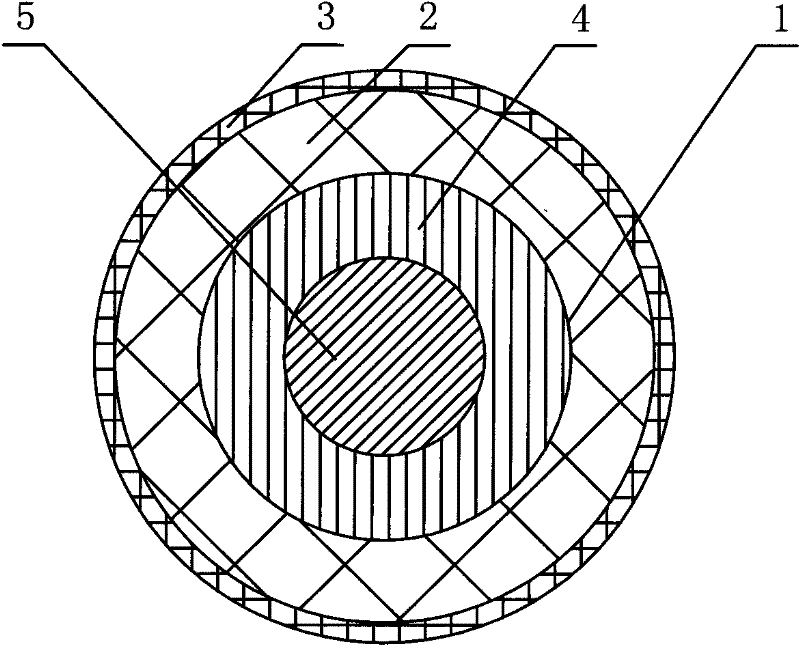

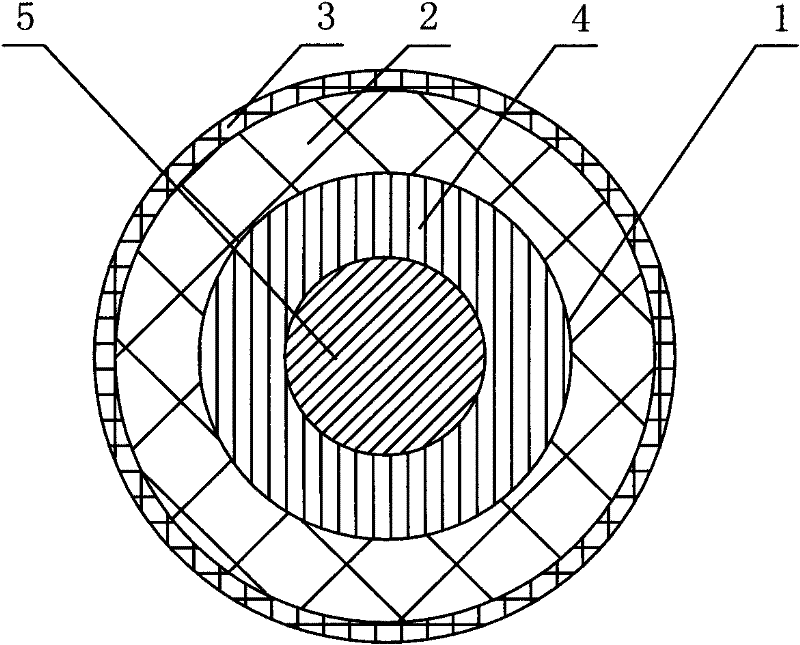

[0011] As shown in the figure, the double-layer metal-cored flame-retardant wire and cable of the present invention is formed by covering the insulating layer 2 and the conductive core wire 1. The conductive core wire 1 is composed of double-layer coatings of different metal materials. The conductive core wire 1 shown in the figure is composed of copper 4-coated aluminum core wire, and copper-clad steel or aluminum-clad steel core wire can also be used.

[0012] The insulating layer 2 is a smokeless and flame-retardant nano-modified polyolefin polymer insulating material, and the insulating layer 2 is covered with a flame-retardant sheath 3 . The insulating layer 2 and the flame-retardant sheath 3 are made by mixing nano-modified polyolefin polymers, nano-flame retardants, nano-smoke suppressants and additives. The weight percent of each component is: 30%-95% of nano-modified polyolefin polymer, 0.1-50% of nano-flame retardant, 0.01-50% of nano-smoke suppressant, and 1%-50% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com