Flame retardant yarn, protective fabric and production process

A production process and yarn technology, applied in the direction of yarn, textiles and papermaking, can solve the problem of low yarn strength and achieve the effect of excellent flame retardancy and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

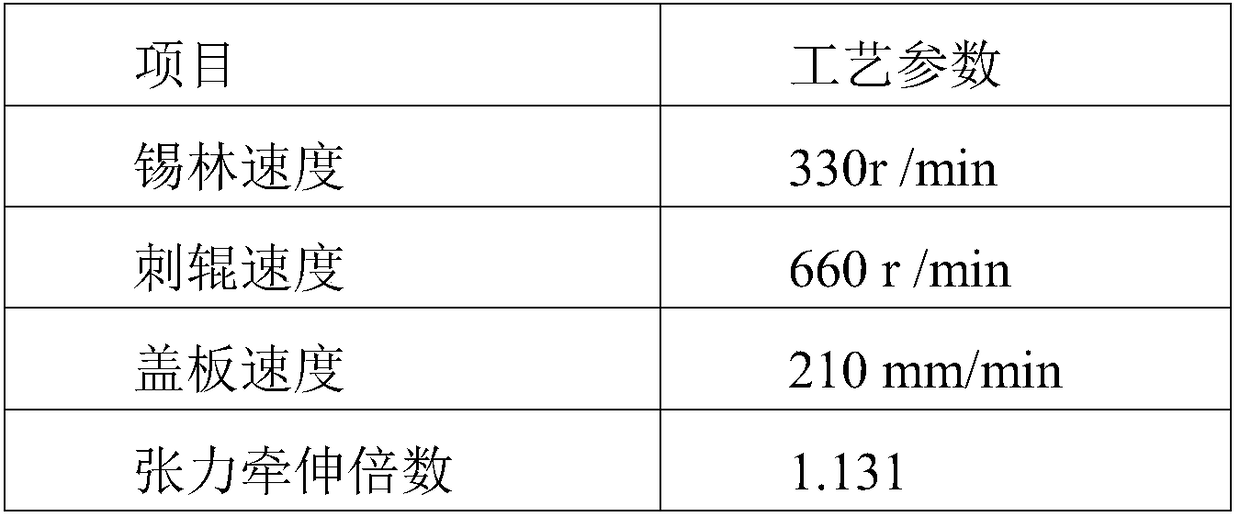

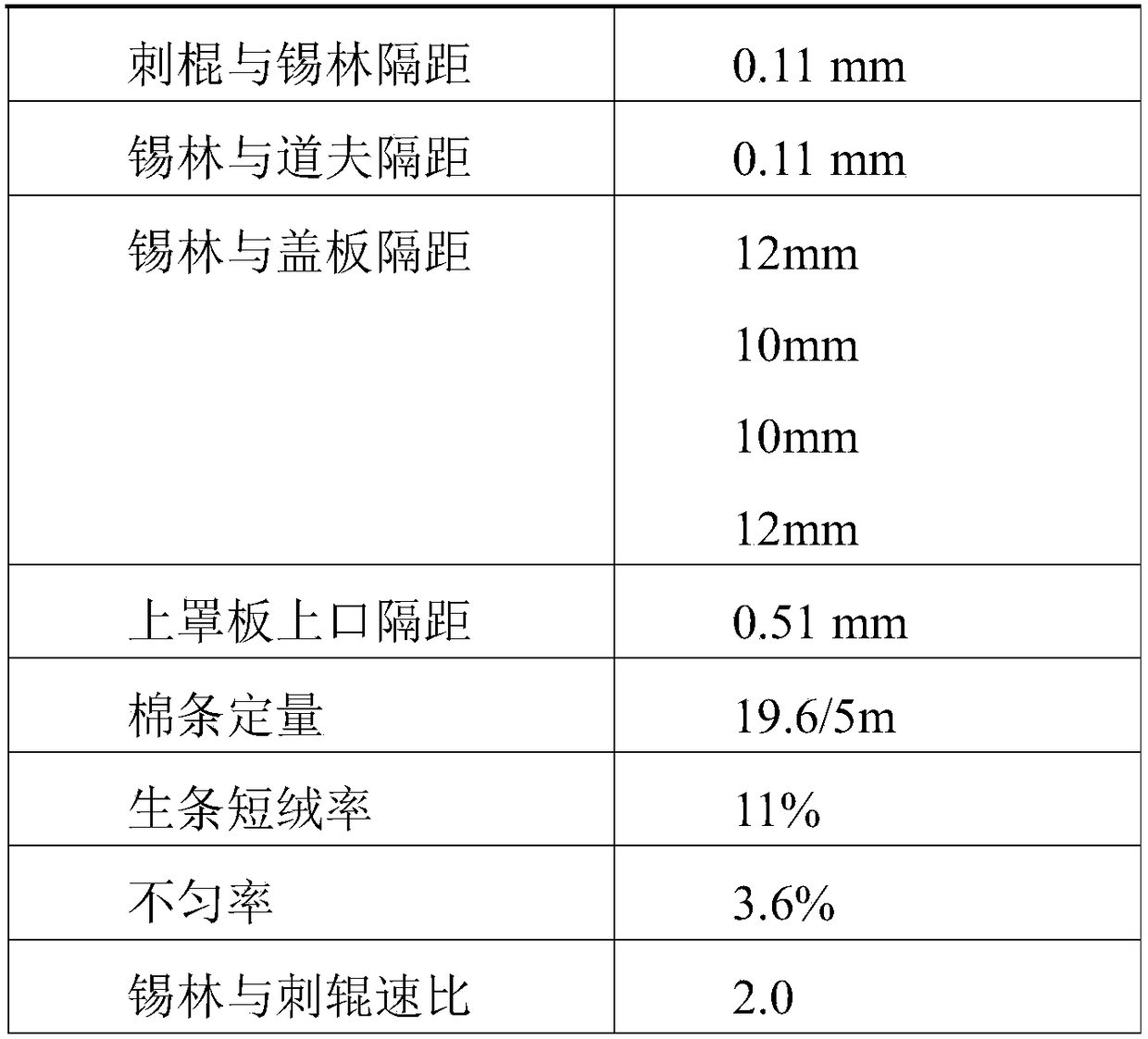

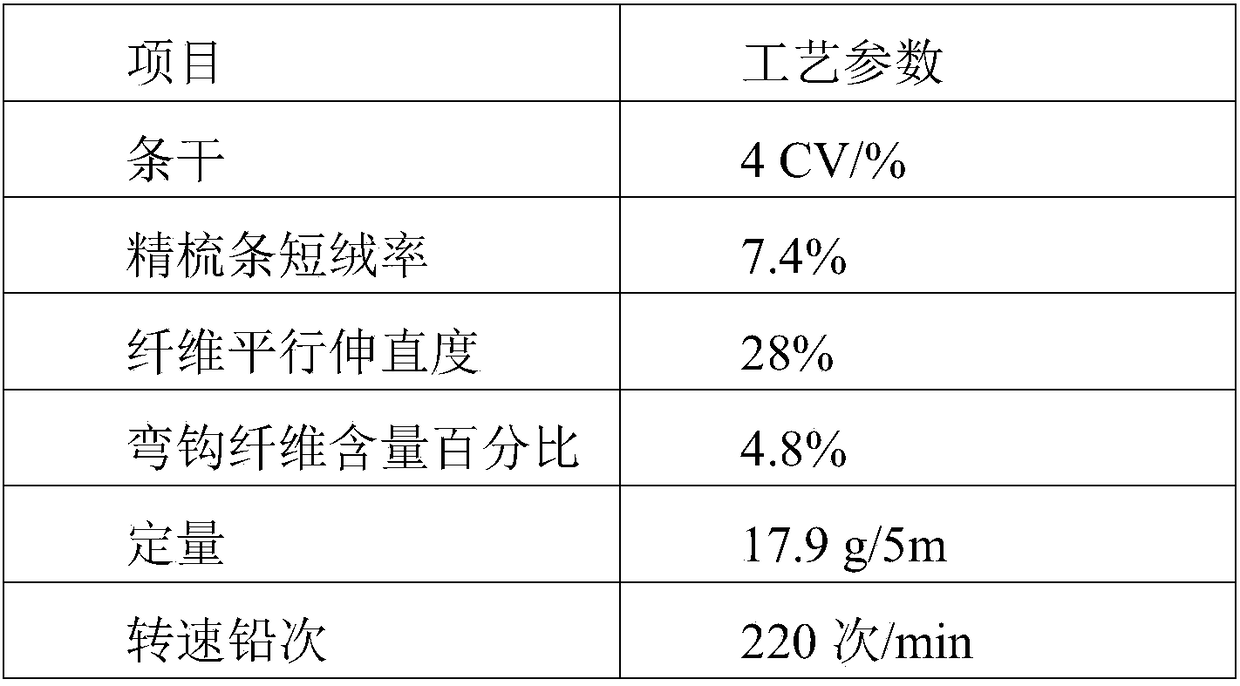

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a flame-retardant yarn, which is prepared from raw materials including the following mass percentages: 60% flame-retardant viscose fiber, 27% para-aramid 1414, 10% nylon and 3% aramid-based conductive fiber . The production process of the flame-retardant yarn of the present embodiment comprises the following steps:

[0041] S1, making mixed fibers:

[0042] According to the proportion of flame-retardant yarn in this embodiment, prepare flame-retardant viscose fiber, para-aramid 1414, nylon and aramid-based conductive fiber, and use a mixer to mix the fibers.

[0043] S2, open and clean cotton:

[0044] The four-component fiber is mixed. Since it is all chemical fibers, the focus is on opening, reducing the distance between the beater and the dust bar, reducing the speed of the beater, and closing the distance between the dust bar.

[0045] The domestic equipment A002D type cotton plucking machine is adopted, the main process parameters: the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

| Wet breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com