Doped modified lithium nickel cobalt manganese material, preparation method thereof and lithium ion battery

A lithium-nickel-cobalt-manganese, modified technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as battery capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

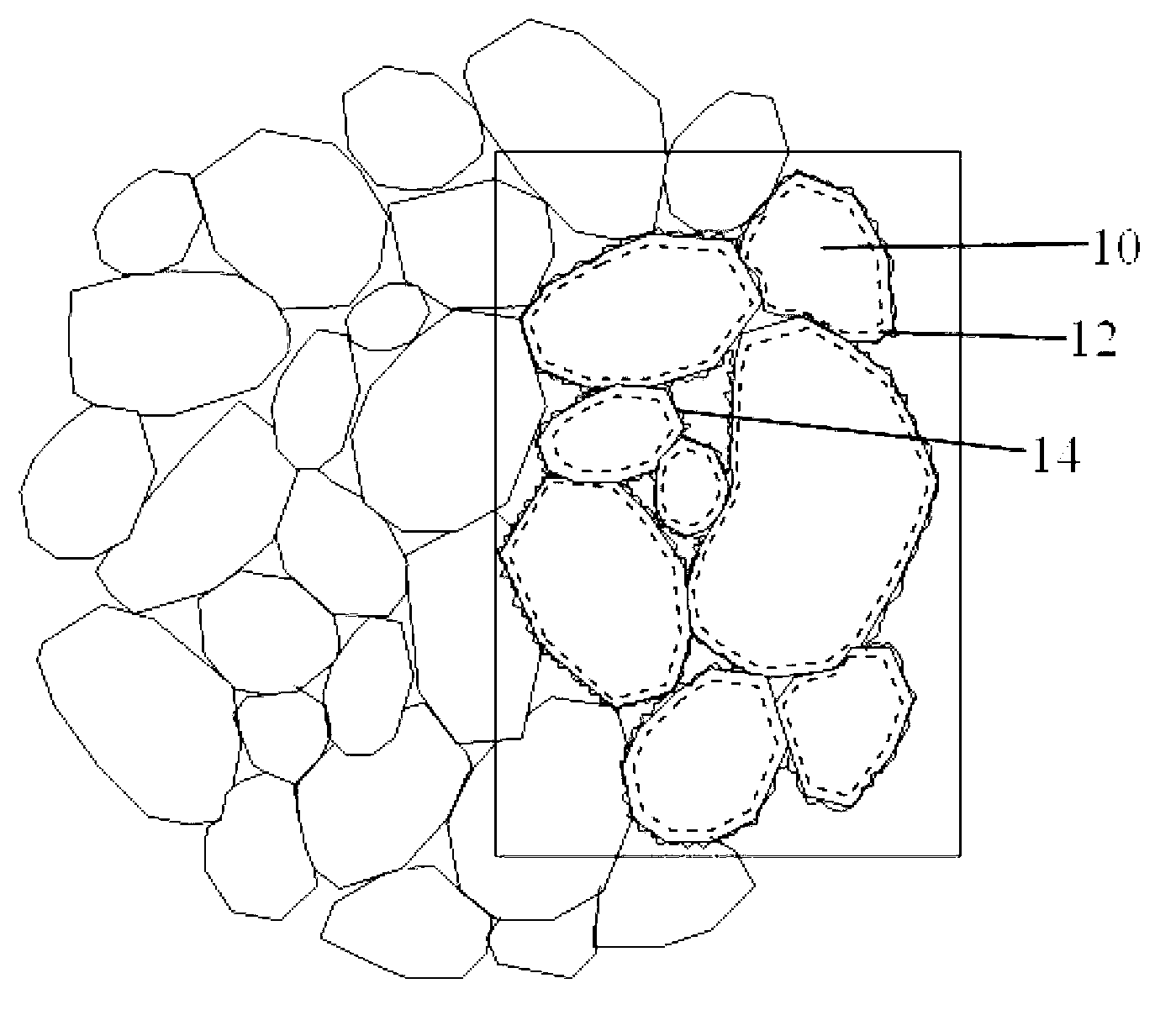

Image

Examples

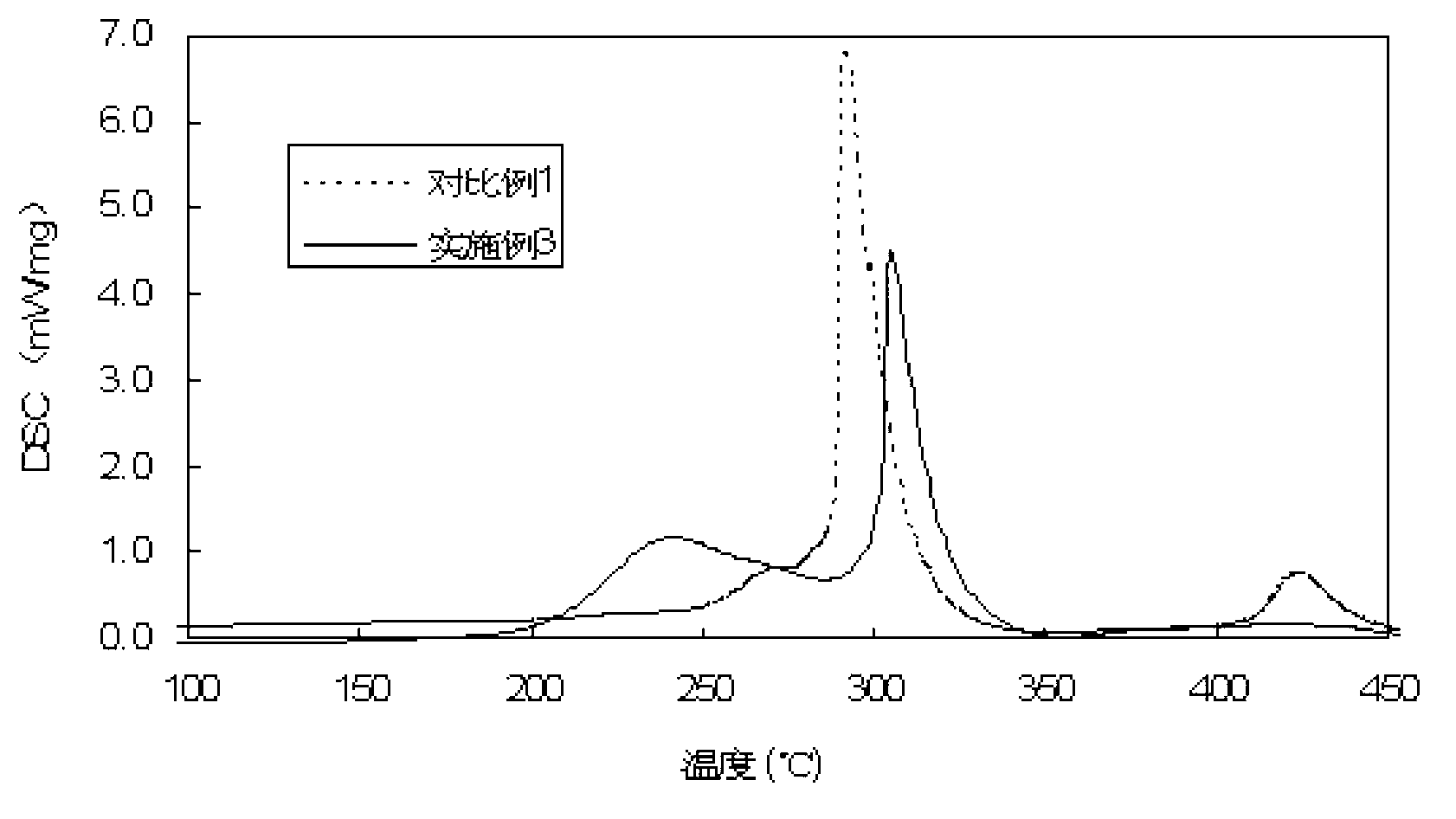

Embodiment 1

[0033] 1) According to the molecular formula Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 The proportion of transition metals to prepare NiSO 4 、CoSO 4 , MnSO 4 1:1:1 mixed aqueous solution, so that the concentration of cations in the mixed solution is 2mol / L, and is added dropwise to the reaction vessel at a speed of 0.2L / h;

[0034] 2) Add 2mol / L NaOH solution, 3mol / L ammonia solution and the mixed solution dropwise into the reaction vessel, control the pH value of the system at 11.0±0.2, heat the water bath to 50°C; after 12 hours of reaction, add the mass fraction at a certain flow rate 1% Nano Al 2 o 3 Water dispersion, the molar ratio of Al element to the sum of Ni, Co, and Mn elements is 0.001:1, continue to react for 4 hours, stop feeding, and age for 2 hours, after filtering, washing and vacuum drying at 120°C for 8 hours , to obtain the nano-Al 2 o 3 Modified nickel cobalt manganese hydroxide precursor powder;

[0035] 3) The modified powder obtained in step 2) is placed ...

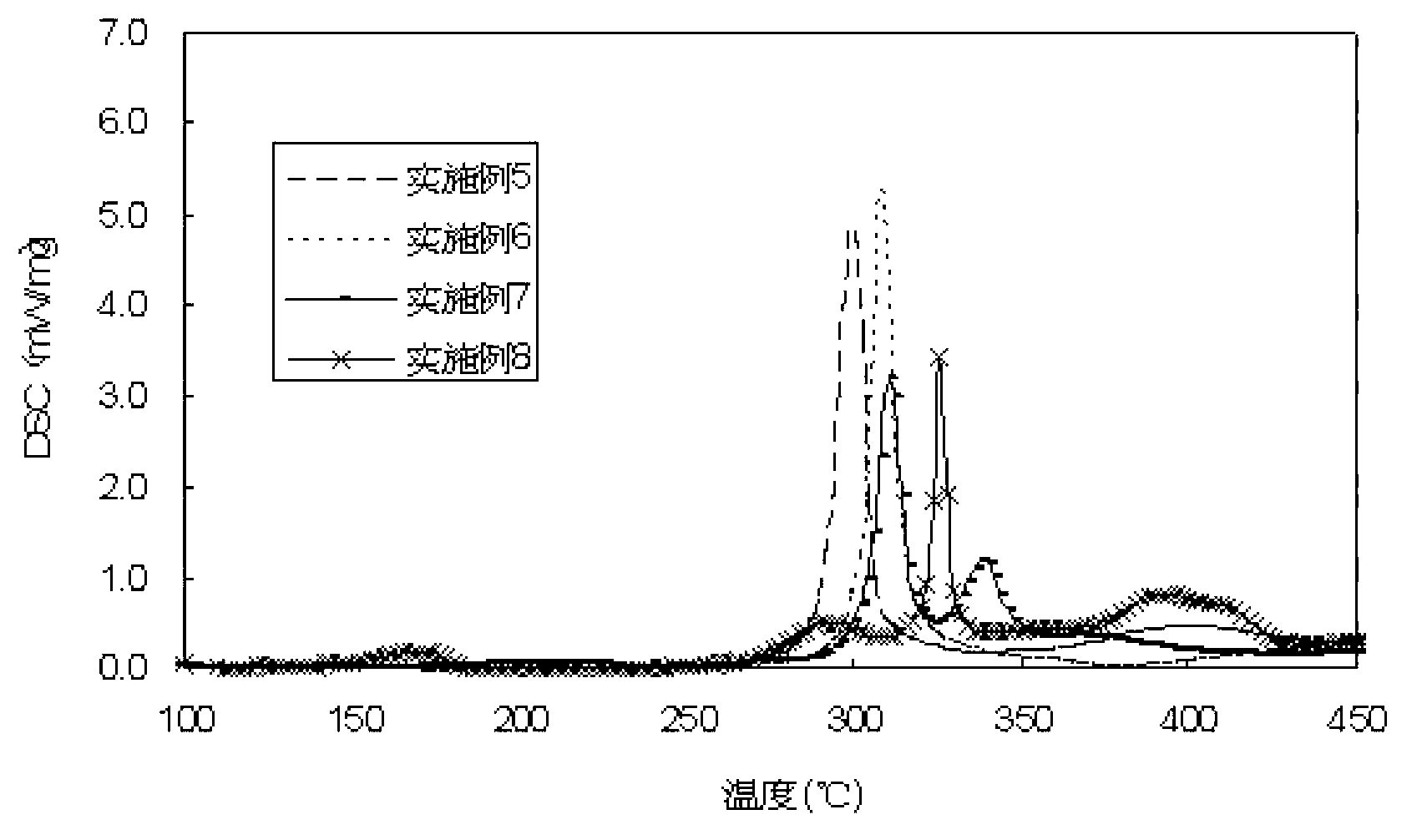

Embodiment 2

[0039] Step 1), 3) are the same as embodiment 1, and step 2), 4) are as follows:

[0040] 2) Add 2mol / L NaOH solution, 3mol / L ammonia solution and the mixed solution dropwise into the reaction vessel, control the pH value of the system at 11.0±0.2, heat the water bath to 50°C; after 12 hours of reaction, add the mass fraction at a certain flow rate 1% Nano Al 2 o 3 Water dispersion, the molar ratio of Al element to the sum of Ni, Co, and Mn elements is 0.005:1, stop feeding after continuing to react for 8 hours, and age for 2 hours, after filtering, washing and vacuum drying at 120°C for 8 hours , to obtain the nano-Al 2 o 3 Modified nickel cobalt manganese hydroxide precursor powder;

[0041] 4) Combine the calcined precursor powder with Li 2 CO 3 According to the molar ratio Li / (Ni+Co+Mn)=1.05:1, mix evenly, and place it in a sintering furnace with an air atmosphere. After sintering at 900°C for 20 hours, the layered crystal structure can be obtained by grinding and si...

Embodiment 3

[0044] Step 1), 3) are the same as embodiment 1, and step 2), 4) are as follows:

[0045] 2) Add 2mol / L NaOH solution, 3mol / L ammonia solution and the mixed solution dropwise into the reaction vessel, control the pH value of the system at 11.0±0.2, heat the water bath to 50°C; after 12 hours of reaction, add the mass fraction at a certain flow rate 1% Nano Al 2 o 3 Water dispersion, the molar ratio of Al element to the sum of Ni, Co, and Mn elements is 0.01:1, continue to react for 8 hours, stop feeding, and age for 2 hours, after filtering, washing and vacuum drying at 120°C for 8 hours , to obtain the nano-Al 2 o 3 Modified nickel cobalt manganese hydroxide precursor powder;

[0046] 4) Combine the calcined precursor powder with Li 2 CO 3 According to the molar ratio Li / (Ni+Co+Mn)=1.05:1, mix evenly, and place it in a sintering furnace with an air atmosphere. After sintering at 900°C for 20 hours, the layered crystal structure can be obtained by grinding and sieving. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com