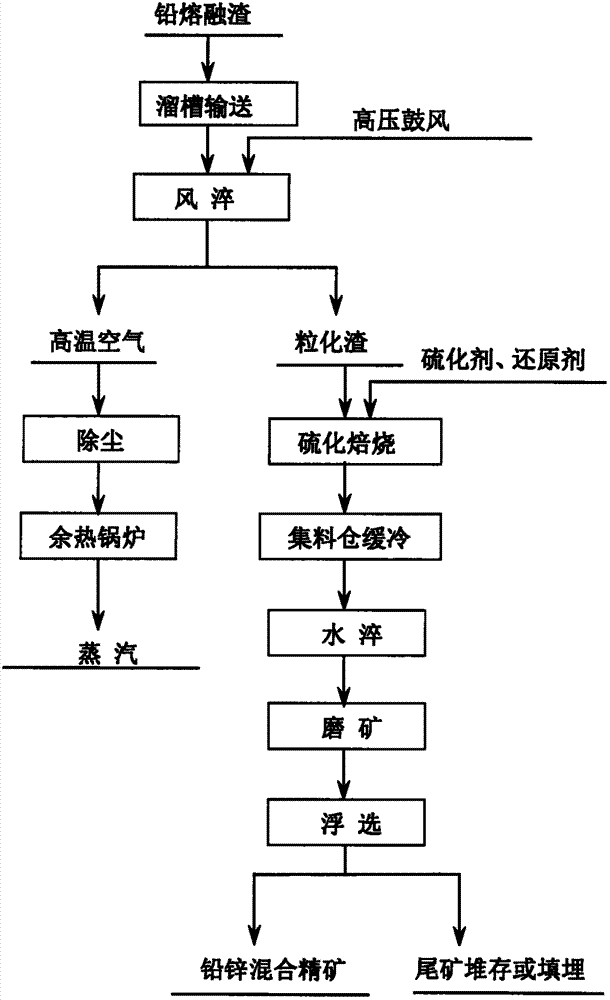

Floating and smelting combined method for air-granulating lead smelting slag and utilizing waste heat

A combination of dressing and smelting, lead smelting technology, applied in the field of dressing and smelting, can solve the problems of complex dust collection system, high energy consumption of fuming furnace, heat loss, etc., and achieve the effect of simple processing flow, low production cost and high utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

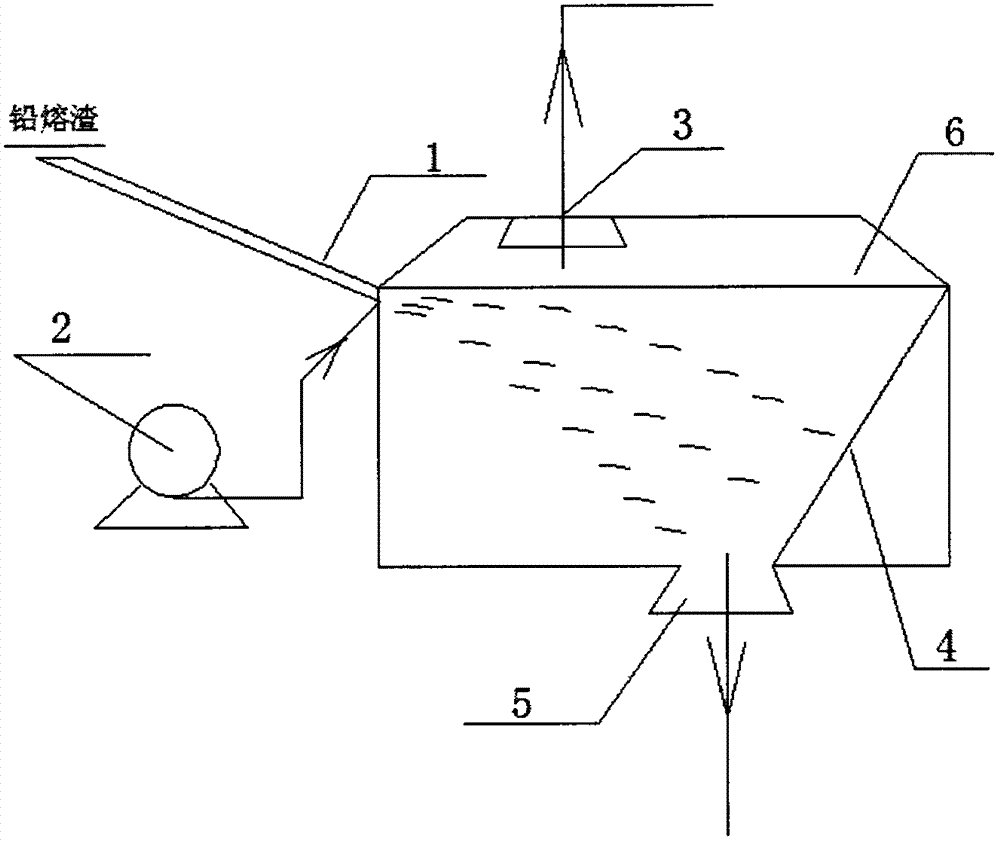

[0055] Embodiment 1: blast furnace lead smelting slag

[0056] Take 1000g of blast furnace water-quenched slag, its chemical composition is: Pb4.0%, Zn18.79%, Fe23.48%, Si9.2%, Ca7.2%, heat treatment on blast furnace slag at 1200 °C for 1h, The molten slag is quickly taken out and poured into the granulator along the chute, and the wind speed is adjusted so that the particle size of the granulated slag is controlled below 1.5mm. After the material is discharged from one end of the granulator, it enters the vulcanization reaction vessel. At the same time, 20% pyrite and 6% coke are added. The temperature is controlled at 800°C and kept at a constant temperature for 2.5 hours. After cooling slowly to below 200°C, it is water quenched. After some materials were dried, the sulfidation rates of lead and zinc were measured to be 82% and 85% respectively through chemical analysis, and the remaining materials were subjected to grinding and flotation tests to finally obtain lead-zinc m...

Embodiment 2

[0057] Example 2: Direct reduction of smelting slag by liquid high-lead slag

[0058] Get 1500g of liquid high lead slag direct reduction smelting slag, its chemical composition is: Pb2.50%, Zn22.79%, Fe21.48%, Si10.2%, Ca9.2%, blast furnace slag is added at 1200 ℃ After warming for 1 hour, the molten slag was quickly taken out and poured into the granulator along the chute, and the wind speed was adjusted so that the particle size of the granulated slag was controlled below 2.0mm. After the material is discharged from one end of the granulator, it enters the vulcanization reaction vessel. At the same time, 25% pyrite and 5% coke are added. The temperature is controlled at 850°C and kept at a constant temperature for 3.0 hours. After cooling slowly to below 200°C, it is water quenched. After some materials were dried, chemical analysis showed that the sulfuration rates of lead and zinc were 85% and 87%, respectively. The rest of the materials were subjected to grinding and flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com