One-step lead smelting process and device for waste lead-acid storage battery lead plaster bottom-blowing smelting

A technology of lead-acid battery and lead paste, which is applied in the field of metallurgy, can solve the problems of large system investment and long process flow, and achieve the effect of high heat utilization rate, less equipment, and increased construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

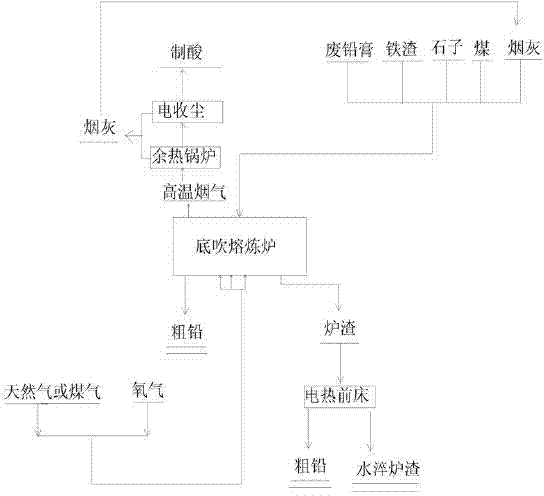

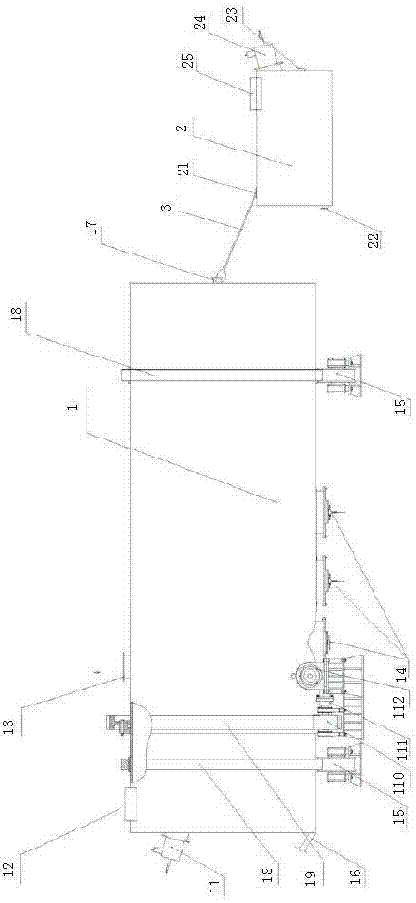

[0047] Such as figure 1 , 2 As shown, a one-step lead smelting process of waste lead-acid battery lead paste bottom blowing smelting, the waste lead paste is mixed with iron slag, stones, coal, and returned soot according to the amount required for the calculation of ingredients, and then it is measured and continuously blown from the bottom. The feeding port 13 of the smelting furnace 1 is fed into the bottom-blowing smelting furnace; the lower part of the 1 keeps a molten pool formed by slag and crude lead, and the gas spray gun 14 installed at the bottom of the bottom-blowing smelting furnace 1 is continuously sprayed into the bottom-blowing smelting furnace 1. Oxygen and natural gas are fed in, and the oxygen and natural gas react with the furnace pellets to generate the same melt, flue gas and soot as the main body of the molten pool; the flue gas and soot are discharged from the exhaust port 12, and after cooling and dust collection, the flue gas is sent to The sulfuri...

Embodiment 2

[0065] Such as figure 1 , 2 As shown, a one-step lead smelting process of waste lead-acid battery lead paste bottom blowing smelting, the waste lead paste is mixed with iron slag, stones, coal, and returned soot according to the amount required for the calculation of ingredients, and then it is measured and continuously blown from the bottom. The feeding port 13 of the smelting furnace 1 is fed into the bottom-blowing smelting furnace; the lower part of the 1 keeps a molten pool formed by slag and crude lead, and the gas spray gun 14 installed at the bottom of the bottom-blowing smelting furnace 1 is continuously sprayed into the bottom-blowing smelting furnace 1. Oxygen and coal gas are fed in, and the oxygen and coal gas react with the furnace pellets to generate the same melt, flue gas and smoke dust as the main body of the molten pool; The sulfuric acid system produces acid, and the smoke and dust return to the furnace for batching; the crude lead is discharged from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com