Method of recycling waste lead acid battery lead by electrolyzing with acid-wet method

An electrolytic recovery and lead-acid battery technology, applied in the field of metal lead, can solve the problems of low lead recovery rate in the process flow, and achieve the effect of reducing investment in fixed assets and environmental treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 10 pieces of 12V, 10Ah electric vehicle batteries from Tianjin Lantian High-Tech Co., Ltd., and the total weight of the battery pack is 42.6 kg. Put 10 batteries into the grinding tool, cut off the upper cover of the battery pack by a cutting machine, and then take out the battery pack by a robot to obtain 60 battery cells.

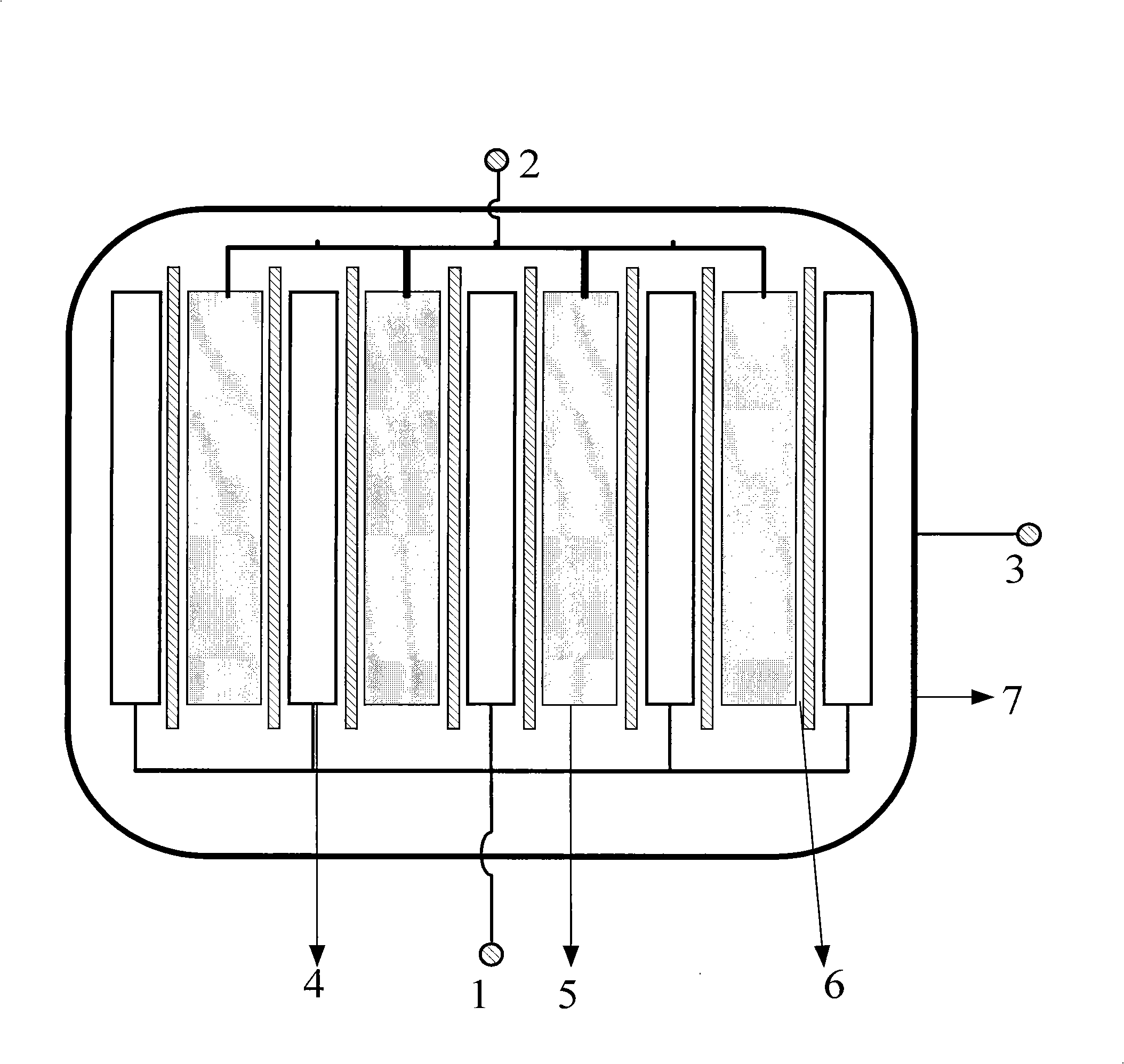

[0028] At this time, the positive and negative poles of the 60 battery cells are connected in parallel with wires, and the battery pack is placed on a 17×200×7.5cm 3The inner layer is a PVC plastic groove of 1.5mm lead plate. Then inject 12L tap water into the electrolytic cell, connect the lead electrolytic cell and lead dioxide positive pole group to the positive pole and negative pole of power supply A respectively, and connect the lead dioxide positive pole group and lead negative pole group to the positive pole and negative pole of power supply B respectively Above, a dual-power multi-module electrolysis mode is formed. By adjusting the...

Embodiment 2

[0032] Take 10 pieces of 12V, 45Ah car batteries from Baoding Fengfan Company, and the total weight of the battery pack is 132 kg. Put 10 batteries into the grinding tool, cut off the top cover of the battery pack by a cutting machine, and then pour out the electrolyte into the acid tank to recover sulfuric acid. The inside of the battery is washed with 60 liters of water to remove residual acid from the battery, which is then discharged into the lead-lined electrolyzer. The battery pack of the car battery is taken out by the manipulator, and 60 battery cells are obtained.

[0033] At this time, the positive and negative poles of the 60 battery cells are connected in parallel with the lead wires of the connecting row, and the battery pack is placed in a 45×400×15cm 3 The inner layer is the PVC plastic groove of 2mm lead plate. Then pour an appropriate amount of water into the electrolyzer until the water surface is submerged in the battery pack. Connect the lead electrolyti...

Embodiment 3

[0037] Take 2 pieces of 12V, 135Ah waste lead-acid batteries for trucks from Northeast Storage Battery Company (please specify the battery type), and the total weight of the batteries is about 92 kg. Put 2 batteries into the grinding tool, cut off the battery pack cover by cutting machine, then pour out the electrolyte into the acid tank to recover sulfuric acid. Wash the inside of the battery with 50 liters of water to remove the residual acid of the battery, and then put the acid into the electrolytic cell lined with 3mm pure lead. The battery pack of the car battery is taken out by the manipulator, and 12 battery cells are obtained.

[0038] At this time, the positive and negative poles of the 12 battery cells are connected in parallel with the lead wires of the connecting row, and the battery pack is placed in a 50×140×15cm 3 The inner layer is the PVC plastic groove of 3mm lead plate. Then pour an appropriate amount of water into the electrolyzer until the water surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com