Busbar cast welding device for lead-acid storage battery

A lead-acid battery and confluence board technology, applied in the field of casting and welding devices, can solve the problems of slow air cooling, large environmental pollution, high labor intensity, etc., and achieve the effects of high-efficiency cooling water cooling, compact overall structure, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings.

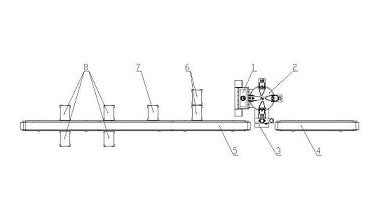

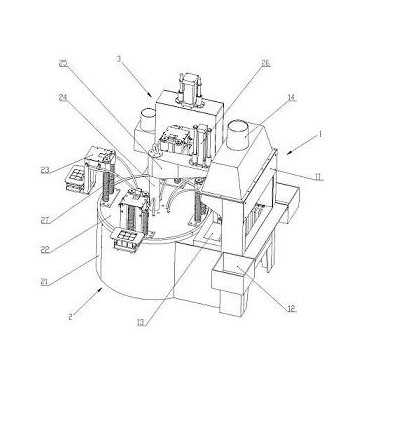

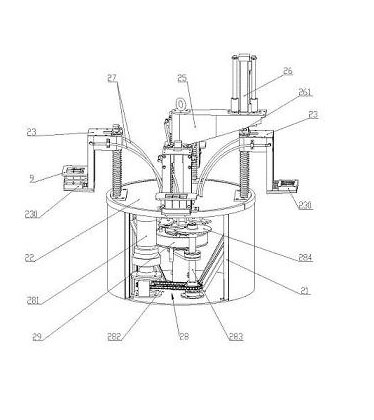

[0027] The main part of the device is made up of a lead melting furnace 1, a demoulding and boxing machine 3 and a workpiece conveyor 2 between the lead melting furnace and the demoulding and boxing machine. The workpiece conveyor 2 is a rotary conveyor with a frame 21 on which a turntable 22 driven by a reduction transmission mechanism 28 for intermittent motion is installed. The lifting frame 23 of the plate casting and welding mold 230 is provided with four stations around the turntable 22. The lead melting furnace is located on the first station, and the lifting frame 23 that the turntable 22 moves to the first station is just positioned at the lead melting furnace 1. Above the liquid pool, a support arm 25 is connected between the upper part of the lead melting furnace 1 and the upper end of the frame central axis 24 of the workpiece conveyor 2 passing through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com