Direct lead-smelting comprehensive metallurgical device and smelting process

A lead smelting and direct technology is applied in the field of non-ferrous metal smelting reaction devices and smelting processes, which can solve the problems of difficulty in recovering sulfur dioxide flue gas from blast furnaces, complicated structures of oxygen blowing lances, and strict requirements for charging materials, and can shorten reduction time and occupy land. Small area and small flue gas output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

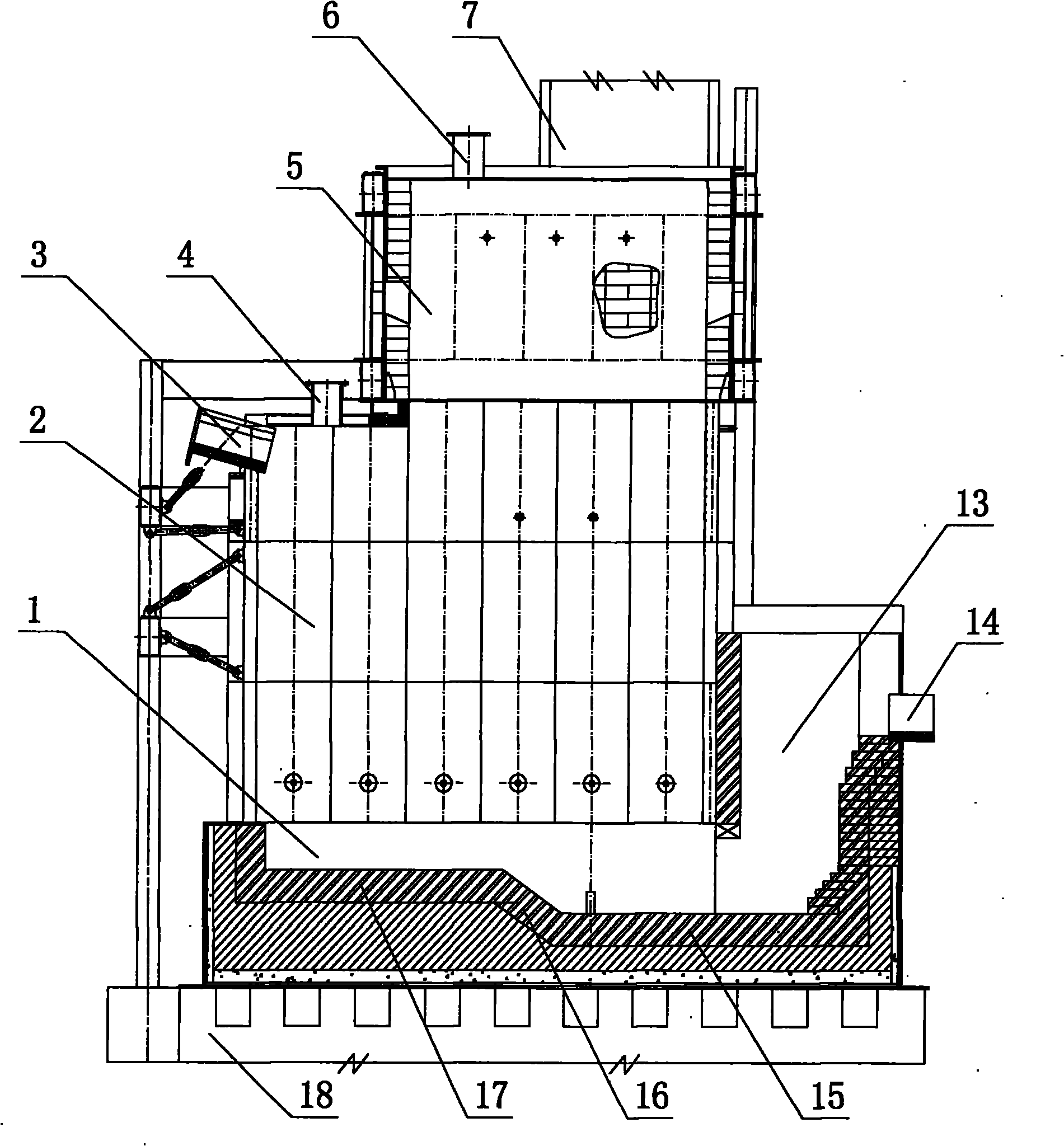

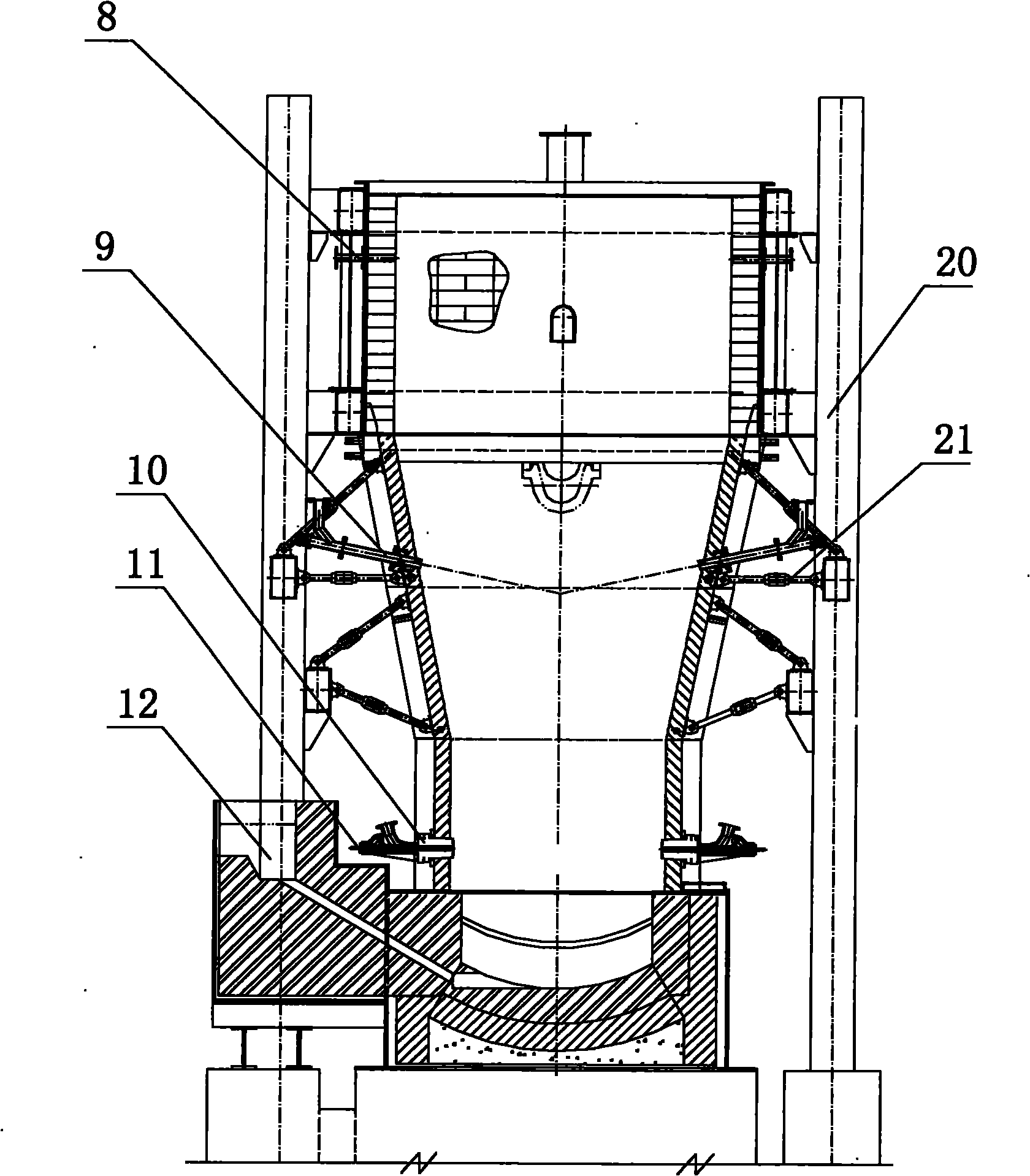

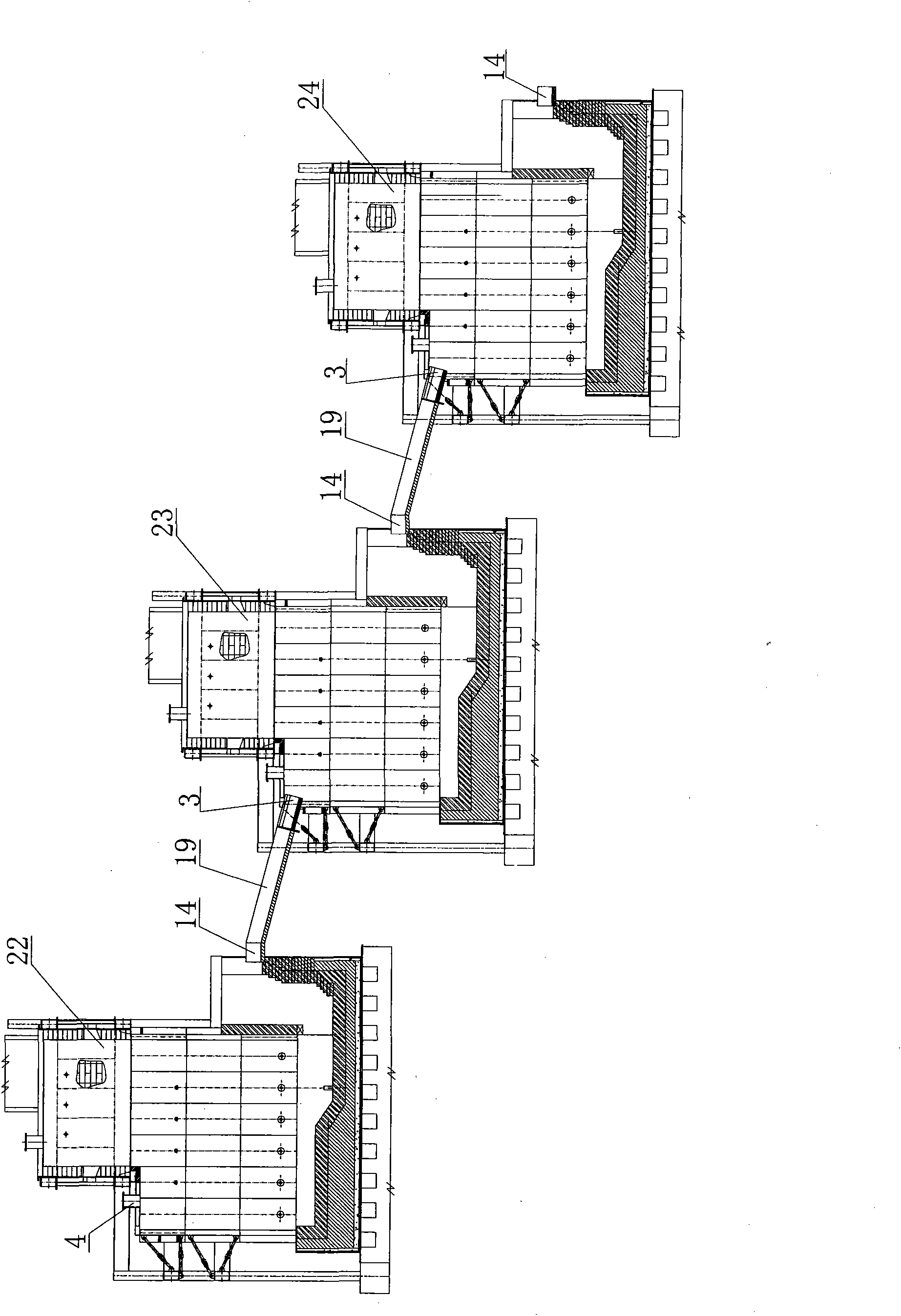

[0013] The comprehensive metallurgical device for direct smelting of lead of the present invention comprises three molten pool smelting furnaces, which are connected together by two connecting chutes. Complete the oxidation of lead concentrate, reduction, and the fuming process of zinc in one step, the specific implementation method is as follows:

[0014] see Figure 1-Figure 3 , the direct smelting comprehensive metallurgical device of the present invention is made up of three melting pool melting furnaces: the first furnace 22, the second furnace 23 and the third furnace 24; the three melting pool melting furnaces are connected in series by two connecting chutes 19 Together: each connection chute 19 is respectively connected between the slag outlet 14 of the previous molten pool melting furnace and the molten slag feeding port 3 of the latter molten pool melting furnace, so that the three molten pool melting furnaces form an integral device.

[0015] Wherein, the structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com