Process of recovering copper smelting waste acid and white smoke dusts

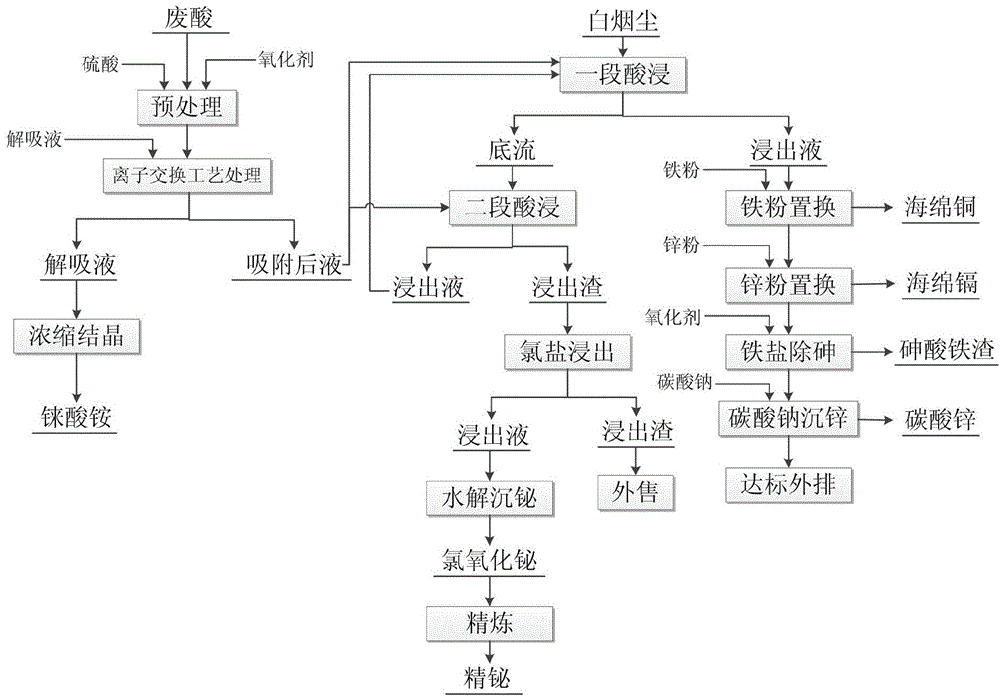

A white smoke, copper smelting technology, applied in the field of metallurgy, can solve the problems of low comprehensive utilization level of valuable elements, poor labor conditions, environmental pollution, etc., and achieve the effects of good wastewater treatment effect, low production cost, and high comprehensive recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A copper smelter produces 800m per day 3 Waste acid (sulfuric acid 150g / L, rhenium 10mg / L, copper 1.5g / L, arsenic 2g / L), produces 4500 tons of white smoke dust (Cu 5%, Bi 8%, Pb 30%, Zn 5%, Cd 3 %, As 5%). Add a small amount of oxidant to the waste acid to adjust the redox potential of the waste acid to 650mV; then use anion resin to adsorb rhenium, the flow rate of the waste acid is 5BV / h, after the adsorption is saturated, use 2mol / L ammonium thiocyanate solution to desorb, the flow rate of the desorption liquid is 2BV / h , the amount of desorption liquid is 5BV, after desorption, the liquid is concentrated and crystallized to obtain ammonium rhenate product. The white soot is subjected to two-stage countercurrent acid leaching, and the concentration of sulfuric acid is adjusted by using the waste acid after adsorbing rhenium. Chloride salt leaching of bismuth is carried out on white fume acid leaching residue, the main component of the leaching residue is lead sulfa...

Embodiment 2

[0026] A copper smelter produces 800m per day 3 Waste acid (sulfuric acid 150g / L, rhenium 10mg / L, copper 1.5g / L, arsenic 2g / L), produces 4500 tons of white smoke dust (Cu 5%, Bi 8%, Pb 30%, Zn 5%, Cd 3 %, As 5%). Add a small amount of oxidant to the waste acid to adjust the redox potential of the waste acid to 650mV; then use anion resin to adsorb rhenium, the flow rate of the waste acid is 8BV / h, after the adsorption is saturated, use 2mol / L ammonium thiocyanate solution to desorb, the flow rate of the desorption liquid is 3BV / h , the amount of desorption liquid is 5BV, after desorption, the liquid is concentrated and crystallized to obtain ammonium rhenate product. The white soot is subjected to two-stage countercurrent acid leaching, and the concentration of sulfuric acid is adjusted by using the waste acid after adsorbing rhenium. Chloride salt leaching of bismuth is carried out on white fume acid leaching residue, the main component of the leaching residue is lead sulfa...

Embodiment 3

[0028] A copper smelter produces 800m per day 3Waste acid (sulfuric acid 150g / L, rhenium 10mg / L, copper 1.5g / L, arsenic 2g / L), produces 4500 tons of white smoke dust (Cu 5%, Bi 8%, Pb 30%, Zn 5%, Cd 3 %, As 5%). Add a small amount of oxidant to the waste acid to adjust the redox potential of the waste acid to 650mV; then use the anion resin to adsorb rhenium, the flow rate of the waste acid is 3BV / h, after the adsorption is saturated, use 2mol / L ammonium thiocyanate solution to desorb, the flow rate of the desorption liquid is 1BV / h , the amount of desorption liquid is 5BV, after desorption, the liquid is concentrated and crystallized to obtain ammonium rhenate product. The white soot is subjected to two-stage countercurrent acid leaching, and the concentration of sulfuric acid is adjusted by using the waste acid after adsorbing rhenium. Chloride salt leaching of bismuth is carried out on white fume acid leaching residue, the main component of the leaching residue is lead su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com