Selecting-smelting method for processing complex hard-washing low ore grade pulmbous sulfide zincium mine

A lead-zinc sulfide, low-grade technology, applied in the field of metallurgy, to achieve the effects of low production cost, favorable flue gas emission, and high recovery rate of lead and zinc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

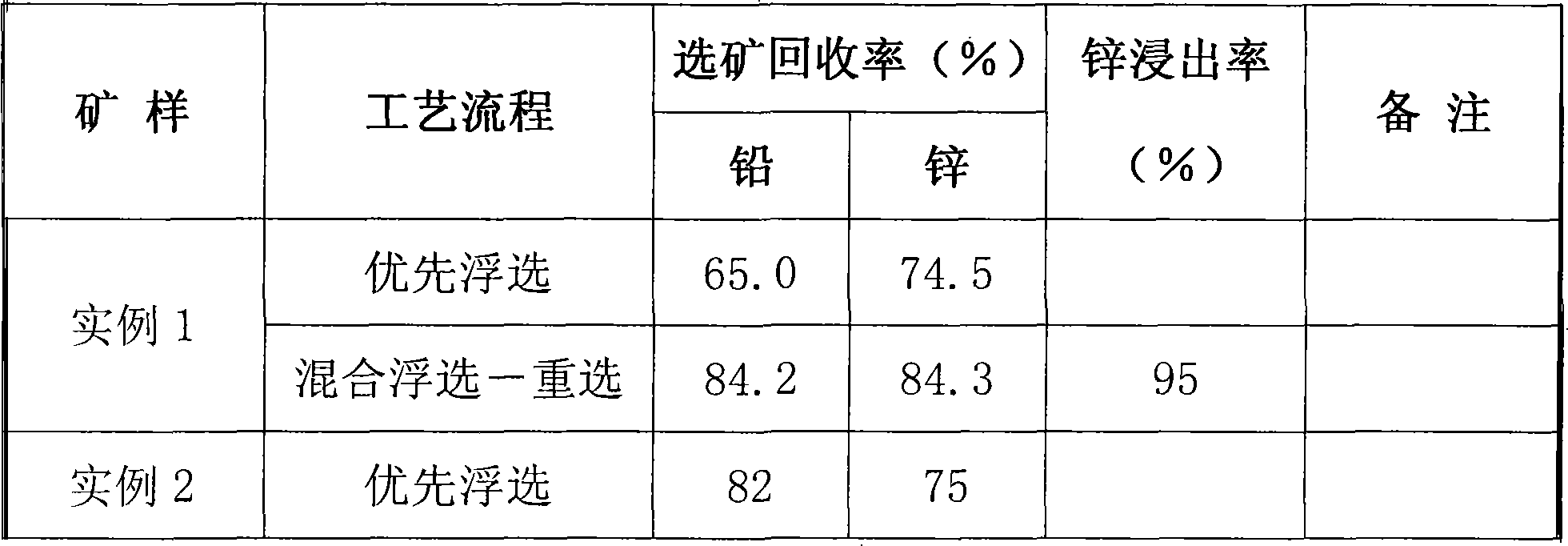

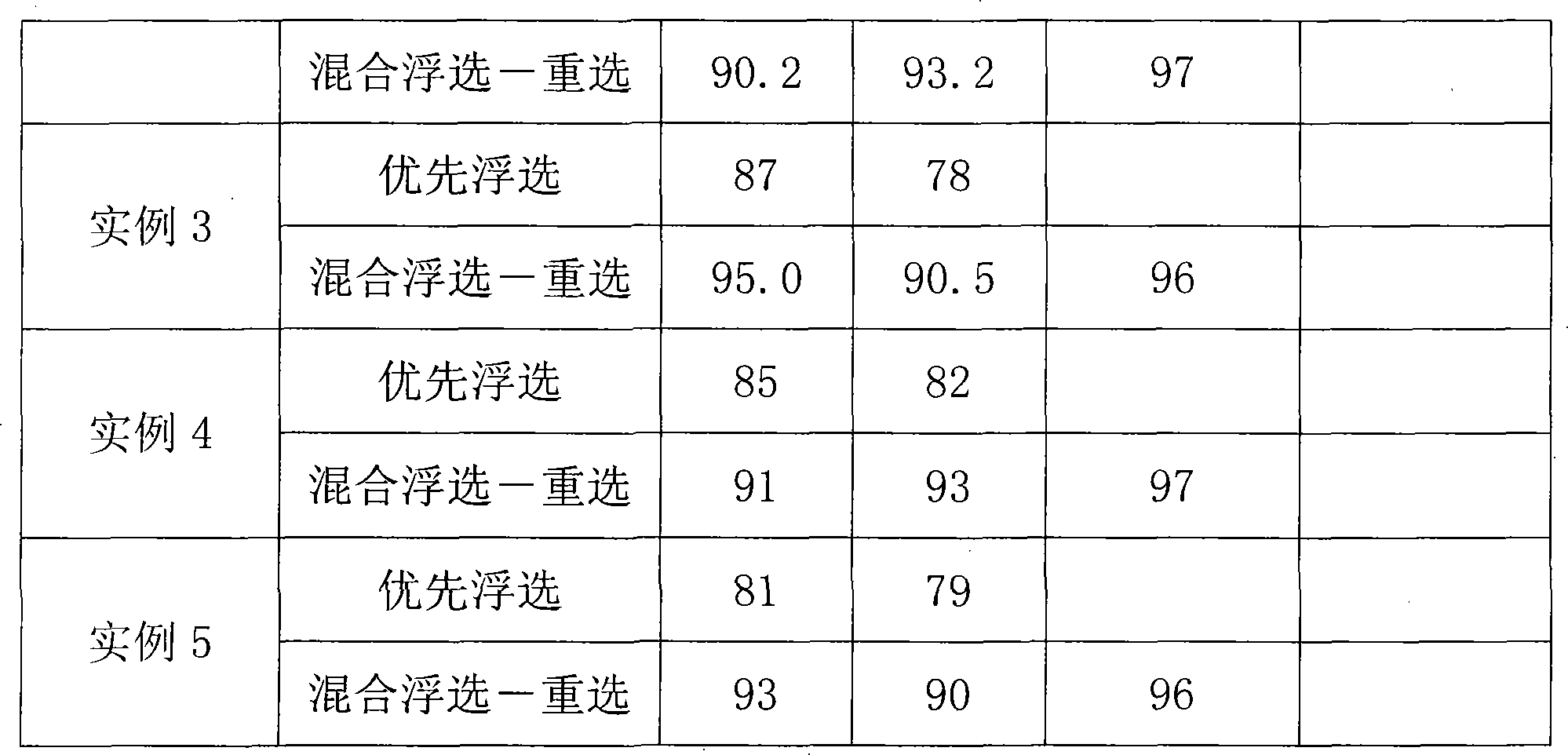

Embodiment 1

[0013] Example 1: Use complex and difficult-to-select low-grade lead-zinc sulfide ore; the raw ore contains 3% lead and 2% zinc; the lead oxidation rate is 19.1%, and the zinc oxidation rate is 21.74%. The flotation process is adopted to obtain the lead-zinc mixed coarse concentrate, and the lead-zinc mixed coarse concentrate is separated by gravity separation; part of the lead concentrate and mixed lead-zinc sulfide concentrate are obtained; the lead concentrate contains 40% lead and 0.1% zinc ; Mixed lead-zinc sulfide concentrate contains 5% lead and 15% zinc.

[0014] The mixed lead-zinc sulfide concentrate is finely ground, the grinding particle size is -0.043mm, which is 70%; the slurry is adjusted with a solution containing sulfuric acid of 80g / L; it is added to the autoclave, the temperature is controlled at 150℃, the pressure is 1.1Mpa, and it is carried out directly Oxygen gas acid leaching; the leaching rate of zinc in the leaching process is 95%; after acid leaching, th...

Embodiment 2

[0015] Example 2: Use complex and difficult to select low-grade lead-zinc sulfide ore; the raw ore contains 10% lead and 10% zinc; the lead oxidation rate is 10.1%, and the zinc oxidation rate is 13.74%. The flotation process is adopted to obtain the lead-zinc mixed coarse concentrate, and the lead-zinc mixed coarse concentrate is separated by gravity separation; part of the lead concentrate and mixed lead-zinc sulfide concentrate is obtained; the lead concentrate contains 80% lead and 2% zinc ; Mixed lead-zinc sulfide concentrate contains 30% lead and 50% zinc.

[0016] The mixed lead-zinc sulfide concentrate is finely ground, the grinding particle size is -0.043mm, which is 100%; the slurry is adjusted with a solution containing sulfuric acid of 110g / L; it is added to the autoclave, the temperature is controlled to 160℃, the pressure is 1.4Mpa, and it is carried out directly Oxygen gas acid leaching, the leaching rate of zinc in the leaching process is 97%; after acid leaching, ...

Embodiment 3

[0017] Example 3: Use complex and difficult-to-select low-grade lead-zinc sulfide ore; the raw ore contains 5% lead and 4% zinc; the lead oxidation rate is 5.42%, and the zinc oxidation rate is 10.57%. The flotation process is adopted to obtain the lead-zinc mixed crude concentrate, and the lead-zinc mixed crude concentrate is separated by gravity separation; part of the lead concentrate and mixed lead-zinc sulfide concentrate are obtained; the lead concentrate contains 50% lead and 0.5% zinc ; Mixed lead-zinc sulfide concentrate contains 20% lead and 24% zinc.

[0018] The mixed lead-zinc sulfide concentrate is finely ground, the grinding particle size is -0.043mm, which is 80%; the slurry is adjusted with a solution containing 100g / L sulfuric acid; it is added to the autoclave, the temperature is controlled at 155℃, the pressure is 1.3Mpa, and it is carried out directly Oxygen gas acid leaching, the leaching rate of zinc in the leaching process is 96%; after acid leaching, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com