Closed-circuit process technique for recovering multiple metals from copper and lead electrolysis anode mud

A process technology and anode slime technology, which is applied in the field of smelting, can solve the problems of waste of resources, large amount of waste liquid and slag, and inability to fully recycle, and achieve the effects of low environmental protection pressure, high recovery rate, and high metal grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

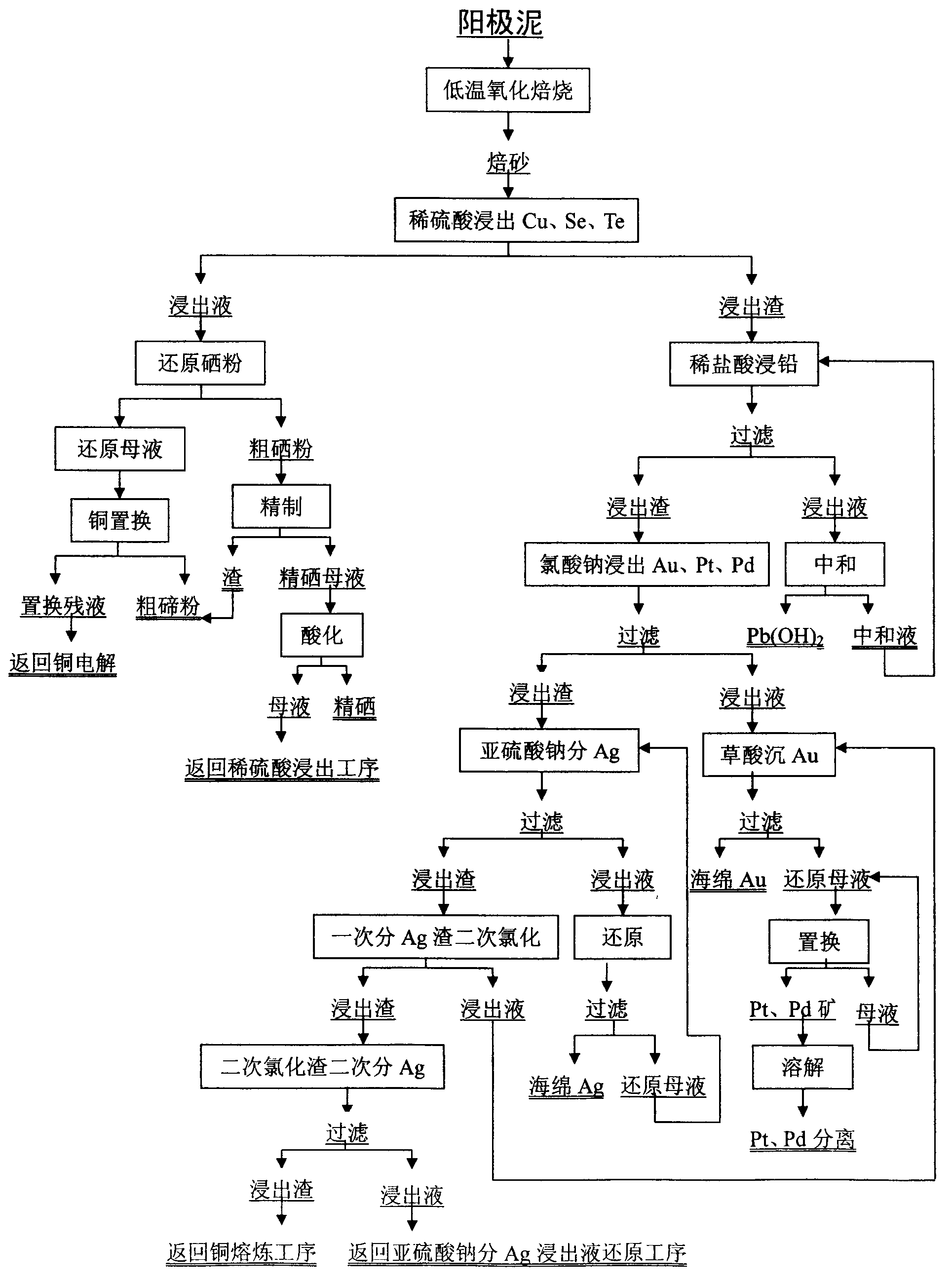

Image

Examples

Embodiment 1

[0031] Embodiment 1: Chemical engineering The following processes are connected to form a closed-circuit process of the present invention.

[0032] Low-temperature oxidation roasting: put the anode slime in the roasting equipment, and oxidize and roast the anode slime at a temperature of 350°C for 8 hours to obtain calcined sand.

[0033] Dilute sulfuric acid leaching of copper, selenium and tellurium: put the calcined sand in the leaching equipment, add sulfuric acid with a concentration of 3N according to the solid-liquid ratio = 1:4-5, and mechanically stir for 2 hours at a temperature of 80-90°C, and wash the obtained filter residue with cold water to colorless.

[0034] Lead leaching with dilute hydrochloric acid: hydrochloric acid concentration 1N, solid-liquid ratio 1:10, temperature above 90°C, leaching with mechanical stirring for 4 hours.

[0035] Neutralization: Use lime to adjust PH=9, stir at room temperature for 15 minutes, filter to obtain Pb(OH) 2 Precipitati...

Embodiment 2

[0048] Embodiment 2: Low temperature oxidation roasting temperature is 360 ℃, all the other are the same as embodiment 1.

Embodiment 3

[0049] Embodiment 3: Low temperature oxidation roasting temperature is 375 ℃, all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com