Method of recycling zinc, manganese, lead and silver from zinc electrowinning anode mud

A technology of anode slime and zinc electrowinning, applied in the field of recovering valuable metals zinc, lead and silver, manganese, and zinc, which can solve the problem of the volatility, strong corrosiveness of hydrogen peroxide, difficulties in production, operation and storage, and large amount of hydrogen peroxide, etc. problems, to achieve the effect of wide source of reducing agent, improved comprehensive recovery and utilization efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

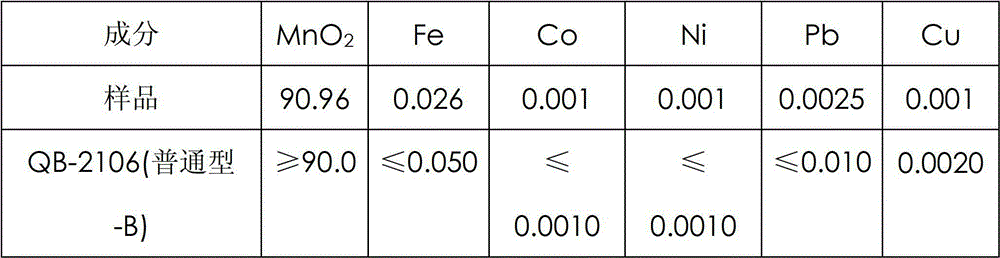

[0021] The composition of zinc electrowinning anode slime is shown in Table 1.

[0022] Table 1 Composition of zinc electrowinning anode slime

[0023] the element

Zn

mn

Pb

Ag

Content (%)

2.44

24.31

9.84

639g / t

[0024] Add block, flake and slurry zinc electrowinning anode slime and slag washing water to the ball mill, the ratio of zinc electrowinning anode to slag washing water is 1:3, the ball milling time is 2 hours, and the particle size of the anode slime after ball milling is 180 mesh , filtered to obtain a solution containing 9.31g / L of zinc, and the filtrate was used as a raw material for the zinc smelting system. Then, according to the solid-to-liquid ratio of 1:3, rinse the filter residue for 1 hour. After filtering, the zinc concentration in the residue washing water is 0.88g / L, and the zinc content in the residue is 0.092%.

[0025] Add the filter residue after rinsing into the reaction kettle equipped ...

Embodiment 2

[0030] Raw material composition is with example 1.

[0031] Add block, flake and slurry zinc electrowinning anode slime and slag washing water to the ball mill, the ratio of zinc electrowinning anode to slag washing water is 1:5.5, the ball milling time is 1h, and the particle size of the anode slime after ball milling is 180 mesh , filtered to obtain a solution containing 6.08g / L of zinc, and the filtrate was used as a raw material for the zinc smelting system. Then, according to the solid-to-liquid ratio of 1:5, rinse the filter residue for 1 hour. After filtering, the zinc concentration in the washing residue water is 0.61g / L, and the zinc content in the residue is 0.073%.

[0032] Add the filter residue after rinsing into the reaction kettle equipped with sulfuric acid solution, control the mass ratio of filter residue to sulfuric acid solution at 1:4, control the pH value of sulfuric acid solution at 1, and slowly introduce sulfur dioxide gas during the stirring reaction ...

Embodiment 3

[0035] Raw material composition is with example 1.

[0036]Add block, flake and slurry zinc electrowinning anode slime and slag washing water to the ball mill, the ratio of zinc electrowinning anode to slag washing water is 1:2, the ball milling time is 3 hours, and the particle size of the anode slime after ball milling is 180 mesh , filtered to obtain a solution containing 11.1g / L of zinc, and the filtrate was used as a raw material for the zinc smelting system. Then rinse the filter residue according to the solid-liquid ratio of 1:2. The rinsing time is 1 hour. After filtering, the zinc concentration in the washing residue water is 1.21g / L, and the zinc content in the residue is 0.44%.

[0037] Add the filter residue after rinsing into the reaction kettle equipped with sulfuric acid solution, control the mass ratio of filter residue to sulfuric acid solution at 1:4, control the pH value of sulfuric acid solution at 1, and slowly introduce sulfur dioxide gas during the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com