Method for modifying modified ceramic microfiltration membrane by adopting graphite oxide

A ceramic microfiltration, modification and modification technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of complex process, high manufacturing cost, and difficulty in performance and separation efficiency. Simple process, low cost, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

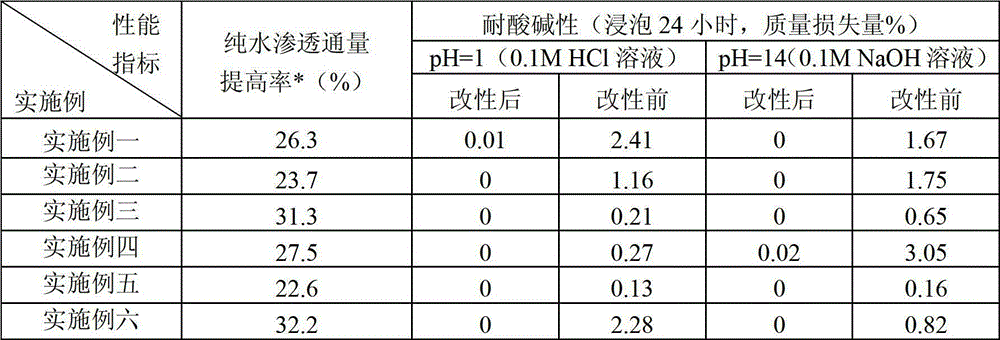

Embodiment 1

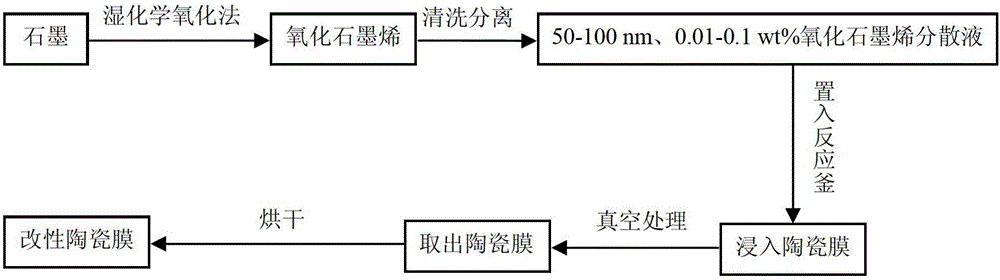

[0018] In this embodiment, a method for modifying a modified ceramic microfiltration membrane using graphene oxide, such as figure 1 As shown, the steps are as follows:

[0019] (1) Preparation of modified solution

[0020] Using flake graphite as raw material, the graphene oxide dispersion aqueous solution was synthesized by the Staudenmaier method; through cleaning, separation, and ultrasonic pulverization, a graphene oxide dispersion with a particle size of 60nm, a solid content of the solution of 0.05wt%, and a uniform and stable dispersion was obtained. aqueous solution;

[0021] (2) Modification and modification treatment

[0022] Put the alumina ceramic microfiltration membrane in the reaction kettle and completely immerse it in the graphene oxide dispersion aqueous solution, adopt the method of vacuum impregnation coating, that is, vacuumize after sealing, and keep it for 1 hour after reaching the vacuum degree of -0.8bar. The filter membrane is modified by graphene...

Embodiment 2

[0026] In this embodiment, a method for modifying a modified ceramic microfiltration membrane using graphene oxide, such as figure 1 As shown, the steps are as follows:

[0027] (1) Preparation of modified solution

[0028] Using expandable graphite as raw material, Brodie method is used to synthesize and prepare graphene oxide dispersed aqueous solution; through cleaning, separation and ultrasonic pulverization, graphene oxide particle size is 80nm, solution solid content is 0.05wt%, and the dispersion is uniform and stable. dispersed aqueous solution;

[0029] (2) Modification and modification treatment

[0030] Put the titanium oxide ceramic microfiltration membrane in the reaction kettle and completely immerse it in the graphene oxide dispersion aqueous solution, adopt the method of vacuum impregnation coating, that is, vacuumize after sealing, and keep it for 1.5h after reaching the vacuum degree of -0.8bar. The filter membrane is modified by graphene oxide;

[0031] ...

Embodiment 3

[0034] In this embodiment, a method for modifying a modified ceramic microfiltration membrane using graphene oxide, such as figure 1 As shown, the steps are as follows:

[0035] (1) Preparation of modified solution

[0036] Using microcrystalline graphite as raw material, the Hummers method is used to synthesize and prepare graphene oxide dispersed aqueous solution; through cleaning, separation and ultrasonic pulverization, graphene oxide particle size is 50nm, solution solid content is 0.02wt%, and the dispersion is uniform and stable. dispersed aqueous solution;

[0037] (2) Modification and modification treatment

[0038] Put the zirconia ceramic microfiltration membrane in the reaction kettle and completely immerse it in the graphene oxide dispersion aqueous solution, adopt the method of vacuum impregnation coating, that is, vacuumize after sealing, and keep it for 2 hours after reaching the vacuum degree of -0.6bar. The filter membrane is modified by graphene oxide;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com