Iron oxide red aqueous color paste for wood coating and preparation thereof

A technology of iron oxide red and water-based color paste, applied in the direction of pigment paste, etc., can solve the problems of high pigment density, poor dispersion stability, precipitation and agglomeration, etc., achieve good thixotropic performance, avoid adverse effects, and be compatible sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

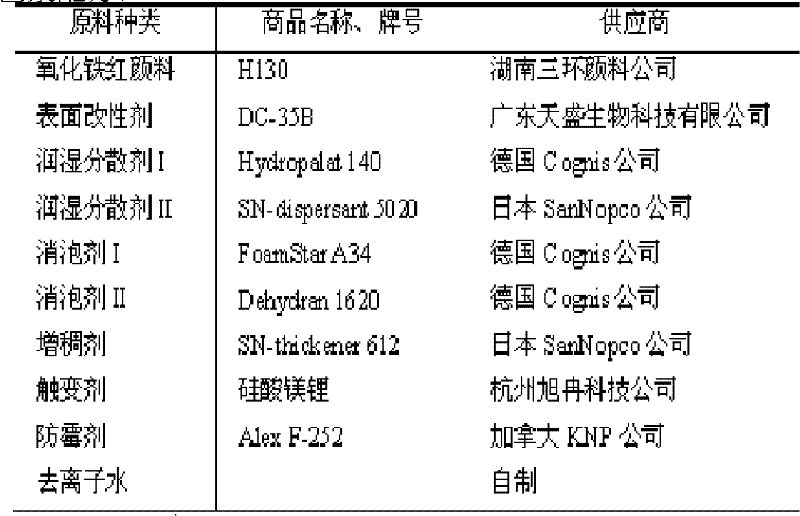

[0050] Embodiment 1: Preparation of iron oxide red water-based color paste

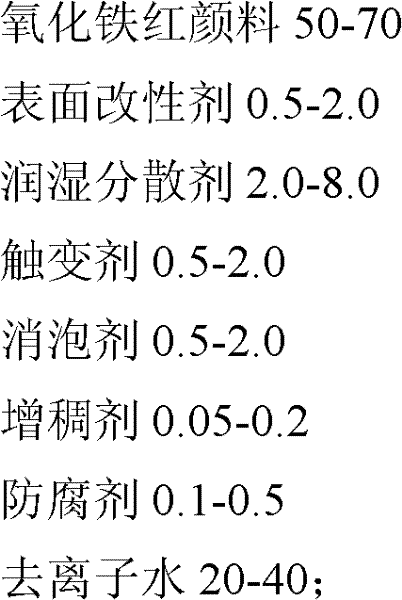

[0051] Color paste formula:

[0052]

[0053] Preparation process: Mix 650g of H130, 4.4g of DC-35B, and 20g of deionized water evenly, heat it under stirring, and keep it at 80°C for 1.5h; after cooling down to room temperature, disperse it in a high-speed disperser at 3000rpm for 15min to obtain Surface modified iron oxide red pigment. Place the dispersing tank containing 320g deionized water under the high-speed dispersing machine, turn on 1500rpm, add 5.0g propylene glycol, 4.0g FoamStar A34, 2.4g Dehydran 1620 and 22.0g Hydropalat 140, 16.0gSN-dispersant 5020, mix for 10min; To 1000rpm, slowly add the above-mentioned surface-modified iron oxide red pigment, increase to 3000rpm after adding, disperse for 30min; reduce to 1500rpm, add 1.2g SN-thickener 612, 8.5g lithium magnesium silicate, 2.4g Alex F-252 Mix with 2g FoamStarA34 and 1.2g Dehydran1620 for 15 minutes; stop the machine, let it st...

Embodiment 2

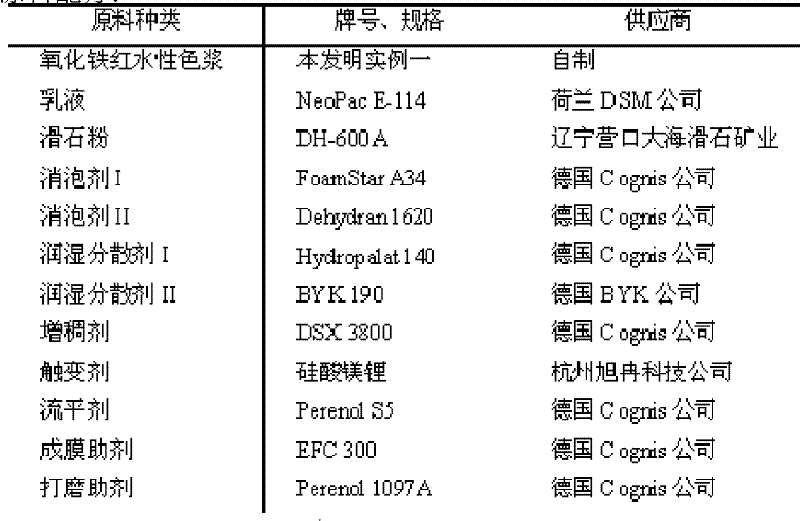

[0060] Embodiment 2: Preparation of iron oxide red dark water-based wood coating

[0061] Coating Formulation:

[0062]

[0063] Preparation process: Place the dispersing tank containing 760g NeoPacE-114 under the high-speed dispersing machine, adjust the speed to 1500rpm, add 70g deionized water, 15g propylene glycol and 25g EFC 300 uniform mixture, mix for 5min; add 1.0g FoamStarA34, 2.0g Dehydran1620, 10.0g Hydropalat140, 20.0g BYK190, mix for 5min; add 100.0gDH-600A, 4.0g magnesium lithium silicate, 40.0g iron oxide red water-based color paste of Example 1 of the present invention, disperse at 2500rpm for 45min; 1500rpm, add 2.0g Perenol 1097A, 5.0g Perenol S5, disperse for 10min; then add 0.5gFoamStarA34, 0.5g Dehydran1620, 1.0g DSX 3800, disperse for 10min; stand for defoaming, filter with 200 mesh screen to get about 1000g iron oxide red Dark water-based paint.

[0064] Main performance indicators (measured according to GB / T23999-2009):

[0065] color dark red

...

Embodiment 3

[0075] Embodiment 3: Preparation of iron oxide red light-colored water-based wood coating

[0076] Coating Formulation:

[0077]

[0078] Preparation process: Place the dispersion tank containing 740g UC81 under the high-speed disperser, adjust the speed to 1500rpm, add a uniform mixture of 70g deionized water, 15g propylene glycol and 25g EFC 300, mix for 5min; add 3.0g DispelairCF707, 25g Dispers 715W, mixed for 5min; added 120.0g R-706, 4.5g lithium magnesium silicate, 50.0g iron oxide red water-based color paste of Example 1 of the present invention, dispersed for 45min at 2500rpm; adjusted the speed to 1500rpm, added 2.0g Perenol1097A, 5.0g BYK 380N, disperse for 10 minutes; add 1.0g Dispelair CF707, 0.8g DSX 3800, disperse for 10 minutes; stand for defoaming, filter with 200-mesh sieve, and obtain about 1000g iron oxide red light-colored water-based paint.

[0079] Main performance indicators (measured according to GB / T23999-2009):

[0080] color light red

[0081]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com