Preparation method for super-hydrophilic foam titanium used for oil-water separation

A titanium foam and super-hydrophilic technology, applied in the field of titanium foam, can solve the problems of unfavorable super-hydrophilic interface construction of nanotube structure, less research, poor stability of super-hydrophilicity, etc., and achieve excellent oil-water separation performance and operation The effect of simple method, simple and easy-to-obtain reagents and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

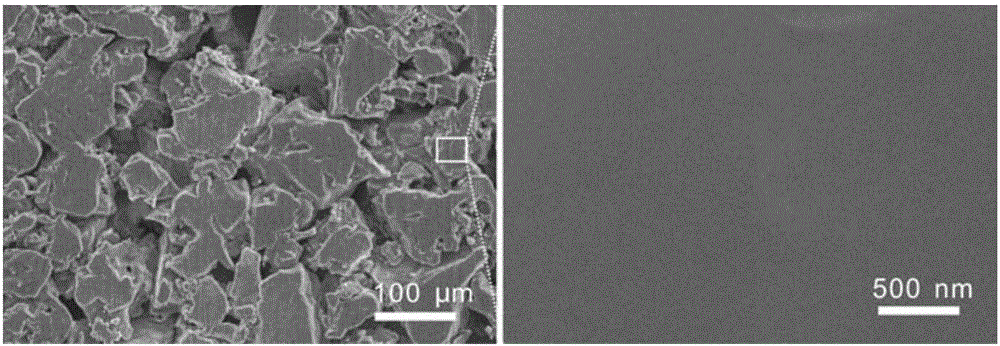

[0027] (1) Pre-treatment of materials: The titanium foam (purity>99.7%) with a separation accuracy of 20 μm and a thickness of 1 mm is ultrasonically cleaned with acetone, ethanol, and deionized water at 80KHZ for 10 minutes to remove surface organic and inorganic pollutants, and then Soak in acetone for later use.

[0028] (2) Anodizing treatment: Weigh 0.3g of ammonium fluoride, add 15g of water and 84.7g of ethylene glycol to prepare 100g of 0.3% by weight ammonium fluoride electrolyte solution for use. Then use titanium foam as the anode, titanium foil as the cathode, and the distance between the two poles is 1.5cm. Under the action of an external DC voltage of 80V, perform anodic oxidation treatment. The temperature of the constant temperature water bath is 25°C. React for 8h, take it out, wash it with deionized water, and then air dry it. .

[0029] (3) UV light treatment: the dried titanium foam sample was treated with 90mW / cm 2 A UV lamp was used to irradiate the sam...

Embodiment 2

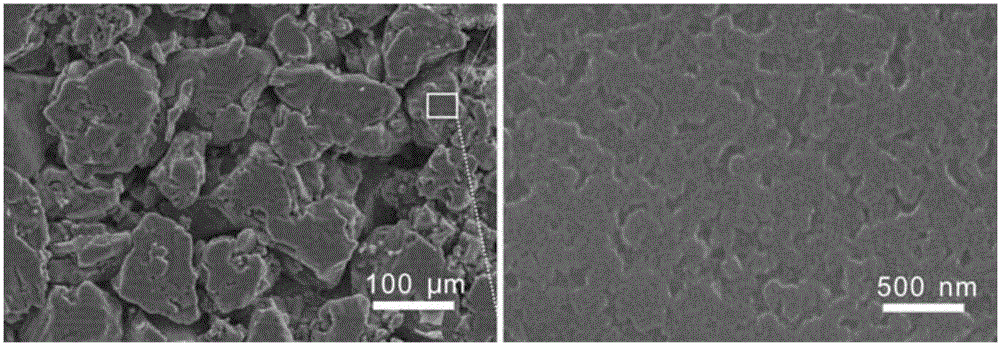

[0032] (1) Pre-treatment of materials: The titanium foam (purity>99.7%) with a separation accuracy of 20 μm and a thickness of 1 mm is ultrasonically cleaned with acetone, ethanol, and deionized water at 80KHZ for 10 minutes to remove surface organic and inorganic pollutants, and then Soak in acetone for later use.

[0033] (2) Anodizing treatment: Weigh 0.4g of ammonium fluoride, add 18g of water and 81.6g of ethylene glycol to prepare 100g of 0.4% by weight ammonium fluoride electrolyte solution for use. Then use titanium foam as the anode, titanium foil as the cathode, and the distance between the two poles is 1.5cm. Under the action of an external DC voltage of 80V, carry out anodic oxidation treatment. .

[0034] (3) UV light treatment: the dried titanium foam sample was treated with 90mW / cm 2 A UV lamp was used to irradiate the sample for 10 minutes at a distance of 20 cm from the sample.

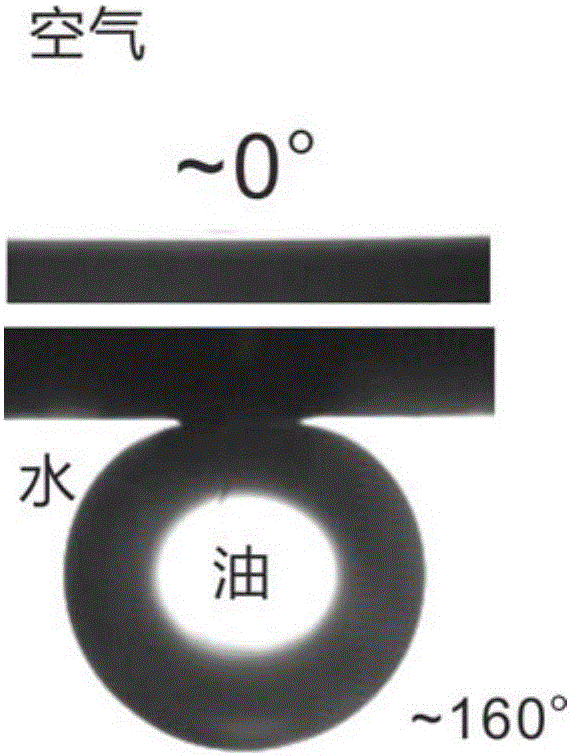

[0035] The obtained material, appearance and oil-water separation performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com