Breathable comfortable moisture-absorption, sweat-releasing and cooling fabric and preparation method thereof

A technology for moisture absorption and perspiration, fabrics, applied in chemical instruments and methods, fabric surface trimming, improved hand-feeling fibers, etc., can solve the problem of rare application of fiber weaving structure, achieve excellent capillary effect, reduce process parameters, and can Manipulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

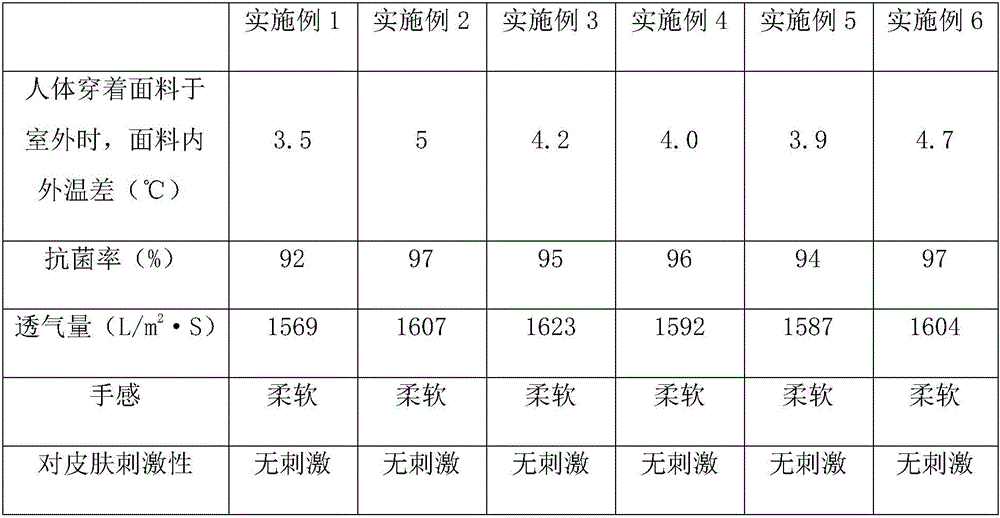

Examples

Embodiment 1

[0029] (1) After the cotton fiber is activated by lye, it is immersed in a chitosan oligosaccharide solution with a mass fraction of 5% and a particle size of 20nm at a bath ratio of 1:30, heated and oscillated at 60°C for 30min, taken out, and vacuum Dry to obtain the cotton fiber modified by nanometer material, wherein the mass ratio of cotton fiber and chitosan in the cotton fiber modified by nanometer material is 6:1.

[0030] (2) Place the superfine polyester fiber in the low-temperature plasma equipment, and carry out surface modification treatment on the superfine polyester fiber under the power of 200W for 5s in the air atmosphere, and obtain a surface modification with grooves with a width of 1nm on the surface superfine polyester fiber.

[0031] (3) Cotton fibers modified by nanomaterials, surface-modified superfine polyester fibers and bamboo fibers are respectively warped, warped and sized to obtain the upper surface layer raw materials of 13.5tex, the middle layer...

Embodiment 2

[0035] (1) After the cotton fiber is activated by lye, soak it in a chitosan oligosaccharide solution with a mass fraction of 10% and a particle size of 40nm at a bath ratio of 1:30, heat and shake at 70°C for 30min, take it out, and vacuum Dry to obtain the cotton fiber modified by nanometer material, wherein the mass ratio of cotton fiber and chitosan in the cotton fiber modified by nanometer material is 10:2.

[0036] (2) Place the ultrafine polyester fiber in low-temperature plasma equipment, and carry out surface modification treatment on the ultrafine polyester fiber under the power of 200W for 20s in the air atmosphere, and obtain a surface containing grooves with a width of 1-5nm on the surface Modified microfine polyester fiber.

[0037] (3) Cotton fibers modified by nanomaterials, surface-modified superfine polyester fibers and bamboo fibers are respectively warped, warped and sized to obtain the upper surface layer raw materials of 14.7tex, the middle layer raw mate...

Embodiment 3

[0041] (1) After the cotton fiber is activated by lye, it is immersed in a chitosan oligosaccharide solution with a mass fraction of 6% and a particle size of 25nm at a bath ratio of 1:30, heated and oscillated at 65°C for 30min, taken out, and vacuum Dry to obtain the cotton fiber modified by nanometer material, wherein the mass ratio of cotton fiber and chitosan in the cotton fiber modified by nanometer material is 7:1.

[0042] (2) Place the superfine polyester fiber in the low-temperature plasma equipment, and carry out surface modification treatment on the superfine polyester fiber under the power of 200W for 10s in the air atmosphere, and obtain a surface modification with grooves with a width of 4nm on the surface superfine polyester fiber.

[0043] (3) Cotton fibers modified by nanomaterials, surface-modified superfine polyester fibers and bamboo fibers are respectively warped, warped and sized to obtain the upper surface layer raw materials of 13.8tex, the middle laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com