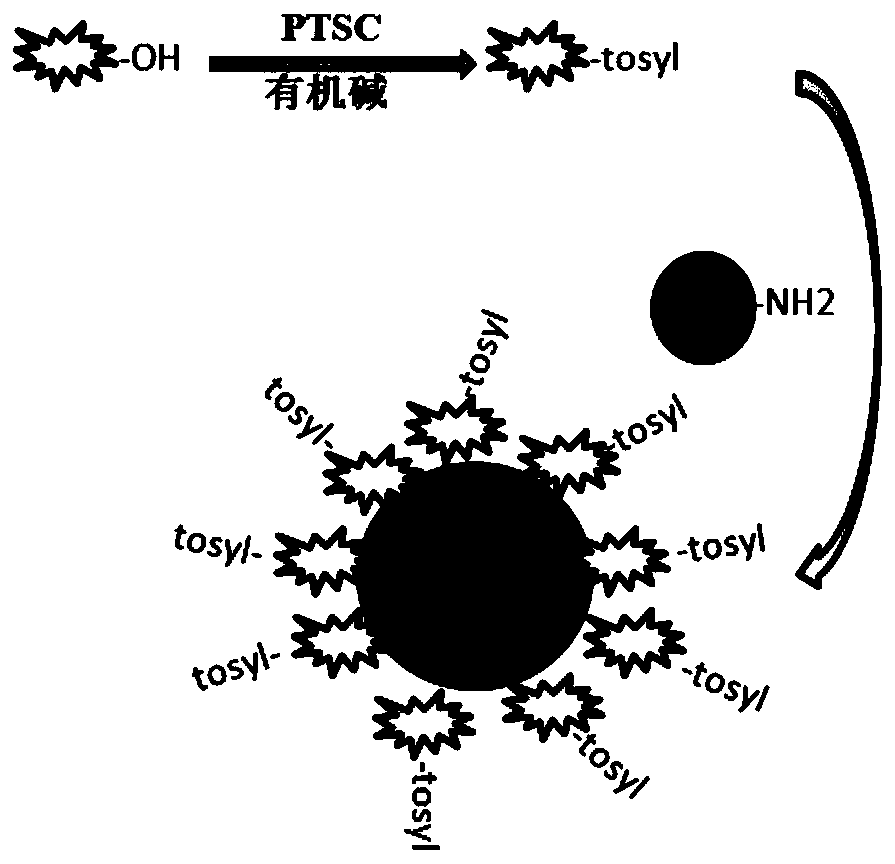

Pre-activated hydrophilic magnetic microsphere and preparation method thereof

A magnetic microsphere, pre-activation technology, applied in the field of materials, can solve the problems of difficult to control batch difference, difficult to long-term storage, harsh storage conditions, etc., and achieve the effects of low cost, strong hydrophilicity, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

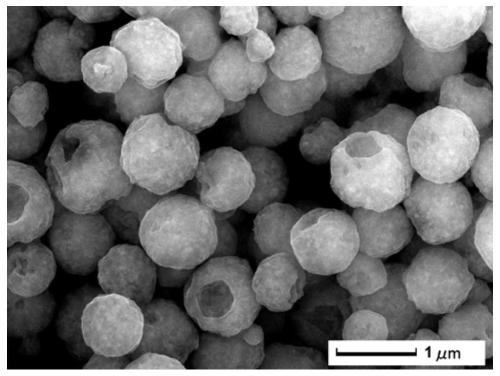

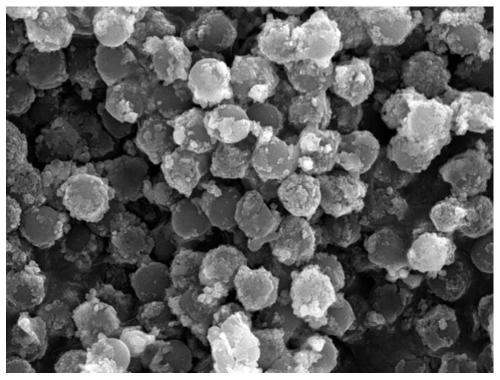

Examples

Embodiment 1

[0038] (1) Prepare a mechanical stirrer and a water bath, install a 100ml three-neck flask, add 20ml of N,N-dimethylformamide, add 10g of polyethylene glycol (molecular weight: 800) while stirring, and stir for about 30 minutes to complete Dissolved, weighed 0.8g of toluenesulfonyl chloride and added to the reaction solution, and at the same time, added dropwise 0.2ml of triethylamine to the reaction solution, and reacted for 6 hours.

[0039] (2) After the reaction is over, prepare several ultrafiltration tubes, dilute the reaction solution with 40ml purified water, put the diluted reaction solution into the ultrafiltration tube, select an ultrafiltration tube with a molecular weight cut-off of 300, and place it in a centrifuge for centrifugation. The machine is set at 4000 rpm. During the ultrafiltration process, a conductivity meter is required for monitoring, and the ultrafiltration is completed until the conductivity is <10us / cm.

[0040] (3) After the dialysis, all the l...

Embodiment 2

[0044] (1) Prepare a mechanical stirrer and a water bath, install a 100ml three-neck flask, add 30ml N,N-dimethylformamide, add 6g polyhydroxyethyl methacrylate (molecular weight: 2500) while stirring, and stir Dissolve completely in about 30 minutes, weigh 0.3 g of toluenesulfonyl chloride and add to the reaction solution, and at the same time add 0.1 ml of triethylamine dropwise to the reaction solution, and react for 6 hours.

[0045] (2) After the reaction is over, prepare some ultrafiltration tubes, dilute the reaction solution with 80ml of purified water, put the reaction solution in the ultrafiltration tube, select the ultrafiltration tube with a molecular weight cut-off of 500, and place it in a centrifuge for centrifugation. The centrifuge is set to 4000 revolutions per minute, a conductivity meter is required to monitor the ultrafiltration process, and the ultrafiltration is completed until the conductivity is <10us / cm.

[0046] (3) After the dialysis, all the liquid...

Embodiment 3

[0050] (1) Prepare a mechanical stirrer and a water bath, install a 100ml three-neck flask, add 70ml of N,N-dimethylformamide, add 7g of polyethylene glycol (molecular weight: 3000) while stirring, and stir for about 30min to complete Dissolved, weighed 0.35g of toluenesulfonyl chloride and added to the reaction solution, and at the same time, added dropwise 0.2ml of pyridine to the reaction solution, and reacted for 6 hours.

[0051] (2) After the reaction is over, prepare some ultrafiltration tubes, dilute the reaction solution with 70ml purified water, put the reaction solution in the ultrafiltration tube, select the ultrafiltration tube with a molecular weight cut-off of 800, and place it in a centrifuge for centrifugation. The centrifuge is set to 4000 revolutions per minute, a conductivity meter is required to monitor the ultrafiltration process, and the ultrafiltration is completed until the conductivity is <10us / cm.

[0052] (3) After the dialysis, all the liquid in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com