Method for surface modification of hydrophobic polymer microporous membrane

A hydrophobic polymer and surface modification technology, applied in the field of surface chemistry, can solve the problems of high price, difficulty in synthesis and extraction, and inability to meet industrial production, and achieve the effect of low equipment requirements, good wettability, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

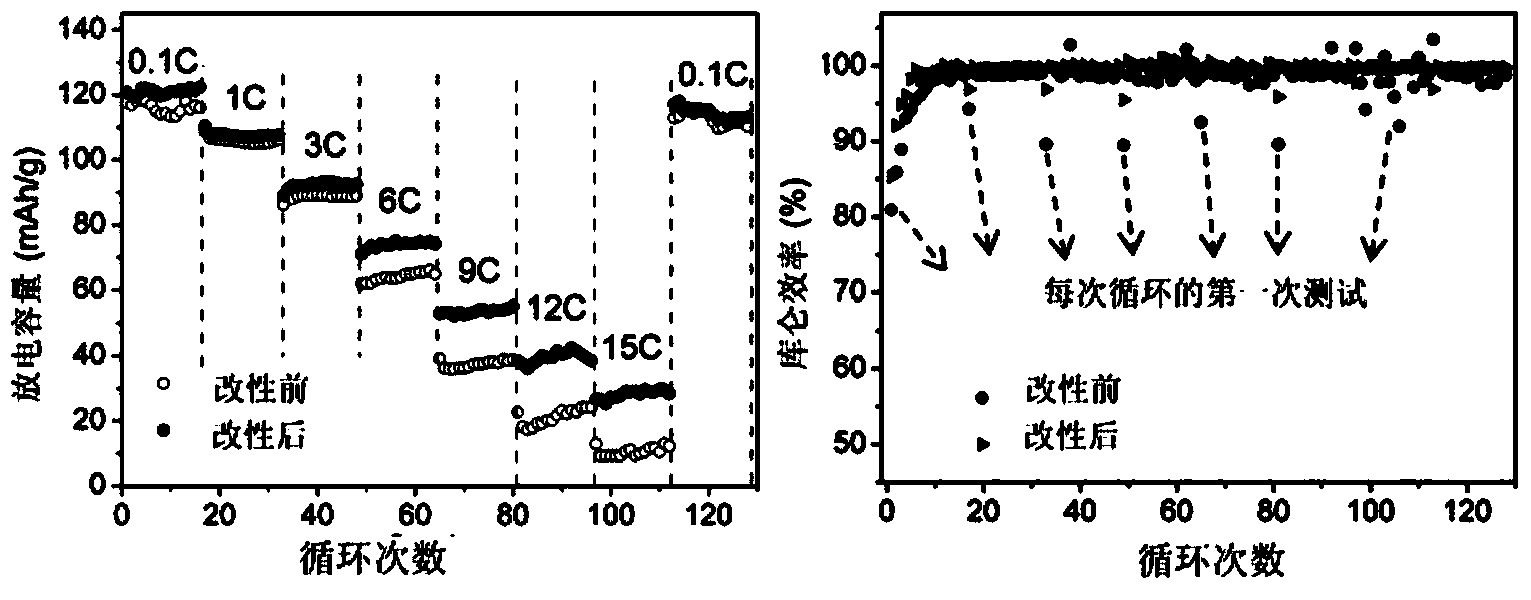

[0039] 50 mg of catechol and 50 mg of ethylenediamine were dissolved in 100 ml of water, and sodium hydroxide was added to adjust the pH of the solution to 13 to obtain a modified solution. A polypropylene microporous membrane (thickness 25 μm, average pore size 0.1 μm, porosity 40%, contact angle of 10 μl water droplet 122°) was immersed in the modification solution. After reacting at 25° C. for 12 hours, the polypropylene microporous membrane was taken out, washed with deionized water and ethanol in turn, and dried to obtain a modified polypropylene microporous membrane.

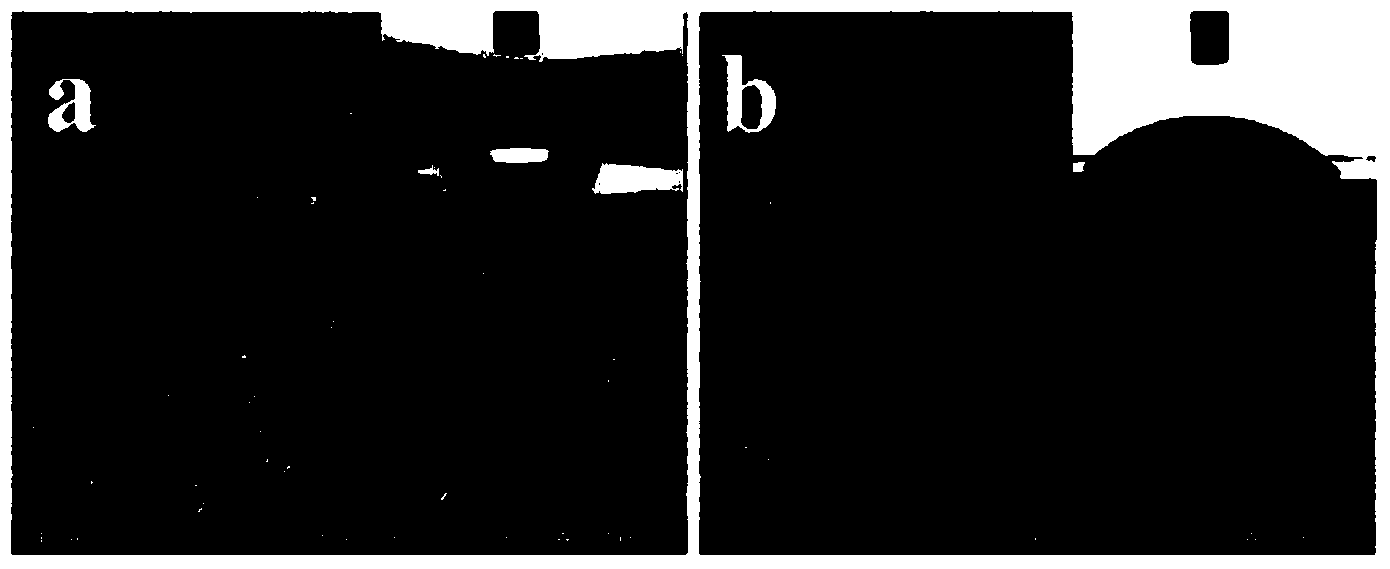

[0040] The modified polypropylene microporous membrane obtained in this example has a brownish yellow color, a thickness of 25 microns, an average pore diameter of 0.1 microns, a porosity of 39.5%, and a contact angle of 10 microliters of water droplets of 47°.

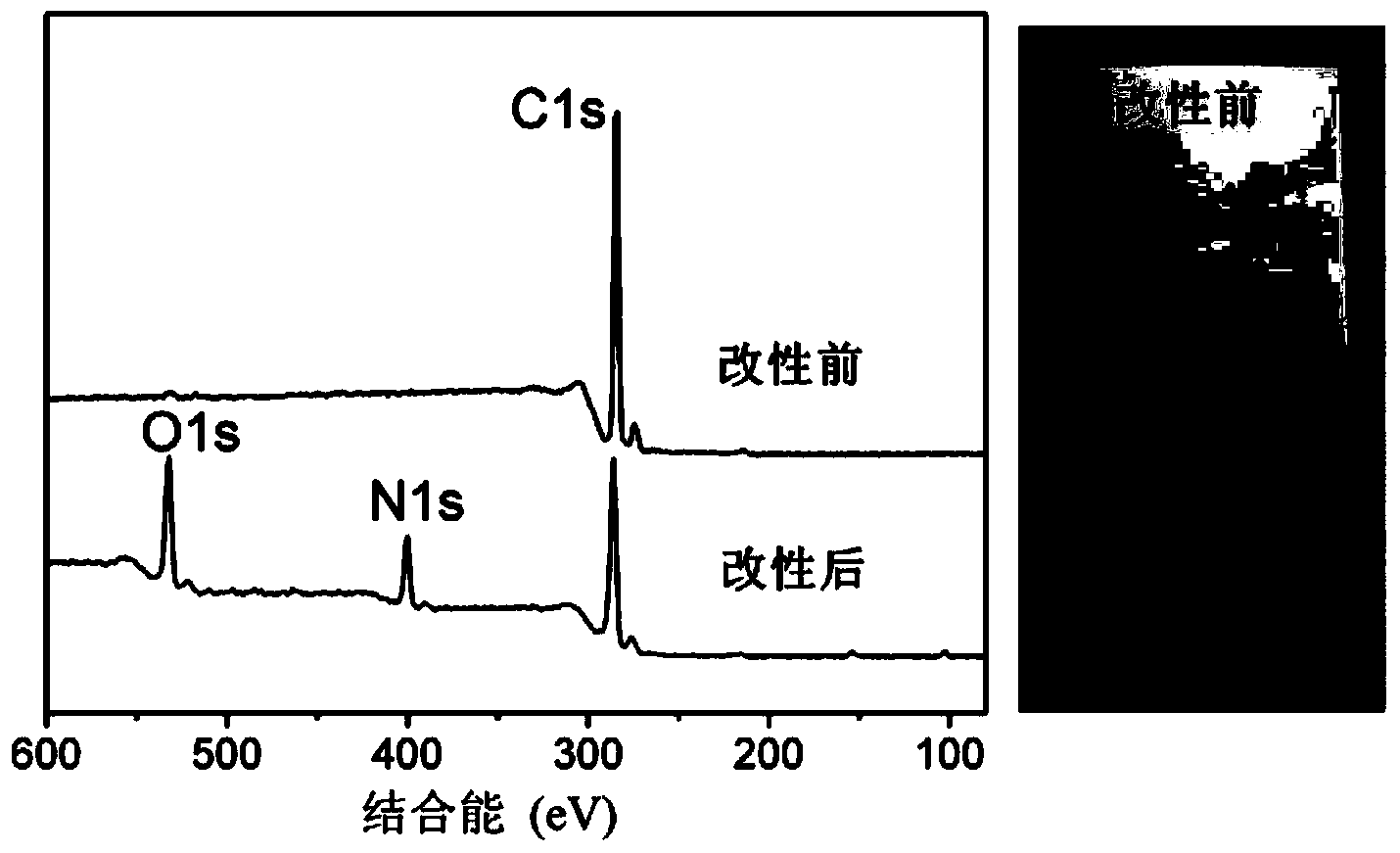

[0041] The X-ray photoelectron spectrum (left picture) and optical photo (right picture) of polypropylene microporous membrane before and after m...

Embodiment 2

[0045] Take 10 mg of 3,4-dihydroxytoluene and 20 mg of butanediamine, dissolve them in 100 ml of water / methanol (1:1 by volume) mixed solvent, add potassium hydroxide to adjust the pH value of the solution to 11 to obtain a modified solvent . Polypropylene microporous membrane (thickness 15 μm, average pore size 0.2 μm, porosity 63%, 10 μl water drop contact angle 120°). Immerse in the modifying solution. After reacting at 35° C. for 8 hours, the polypropylene microporous membrane was taken out, washed with deionized water and ethanol in sequence, and dried to obtain a modified polypropylene microporous membrane.

[0046] The modified polypropylene microporous membrane obtained in this example is brownish yellow, with a thickness of 15 microns, an average pore diameter of 0.2 microns, a porosity of 62.7%, and a contact angle of 10 microliters of water droplets of 46°. It can be seen that the hydrophobic microporous membrane Converted into a hydrophilic microporous membrane, ...

Embodiment 3

[0048] Take 30 mg of 3,4-dihydroxybenzoic acid and 100 mg of hexamethylenediamine, dissolve them in 100 ml of water / ethanol (volume ratio 1:2) mixed solvent, add sodium ethoxide to adjust the pH of the solution to 10 to obtain a modified solution. A polyethylene microporous membrane (thickness 50 μm, average pore size 0.4 μm, porosity 20%, 10 μl water drop contact angle 118°) was used. Immerse in the above solution. After reacting at 25° C. for 10 hours, the polyethylene microporous membrane was taken out, washed with deionized water and ethanol in sequence, and dried to obtain a modified polyethylene microporous membrane.

[0049] The modified polyethylene microporous membrane obtained in this example is brownish-yellow, with a thickness of 50 microns, an average pore diameter of 0.4 microns, a porosity of 19.7%, and a contact angle of 10 microliters of water droplets of 50°. It can be seen that the hydrophobic microporous membrane Converted into a hydrophilic microporous me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com