Biodiesel fuel processing

a biodiesel and fuel technology, applied in the field of biodiesel fuel processing, can solve the problems of reducing the overall time required to produce biodiesel, and achieve the effects of reducing the overall time required to produce, low viscosity, and low molecular weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

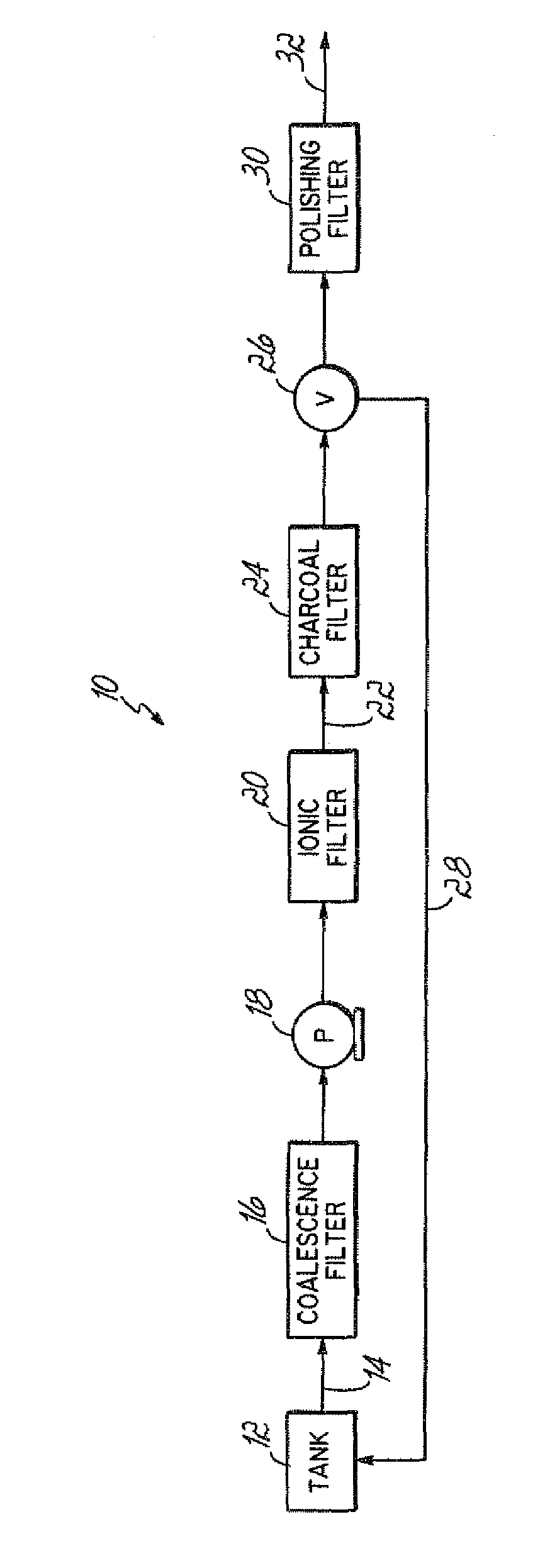

[0025]A biodiesel formulation was formed by combining 100 gallons of degummed soybean oil, 12 gallons of #2 kerosene, 5 gallons of gasoline and 60 ounces of the preferred additive formulation. These were combined together, allowed to sit for 30 minutes, and run through the filtration apparatus described with respect to the FIGURE. In this embodiment, the polishing filter was a 2 micron polishing filter. The formulation was tested after processing and the results are shown in the Table below:

TABLETest DescriptionASTM 6571MethodResultFlash point - deg F.D93>200Water and sedimentD2709Kinematic ViscosityD4454.3Sulfated Ash - % massD874Sulfur - ppmD5453Copper StripD130#1CentaneD61355Cloud Point - deg C.D2500−10Carbon residue - % massD4530Acid Number mg / gmD6640.3Free Glycerin - % massD6584Total Glycerin - % massD65840.23Phosphorous - % massD4951Distillation - temp 90% rec. deg C.D1160330

All of these results are within acceptable limits for diesel fuel.

[0026]This process takes no more than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific gravity | aaaaa | aaaaa |

| cetane rating | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com