Deep dehydrating method and device for oil product

A technology for deep dehydration and oil products, which is applied in the direction of hydrocarbon oil dehydration/demulsification, grease/oily substance/suspton removal device, mechanical dehydration/demulsification, etc., which can solve the problem of large operating pressure drop, short service life, Energy consumption and complex operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Two sets of diesel hydrogenation units in a petrochemical company adopted the method and device for deep dehydration of oil products of the present invention to dehydrate the diesel oil from the fractionation tower of the diesel hydrogenation unit, and the dehydrated diesel oil was sent to the finished oil tank.

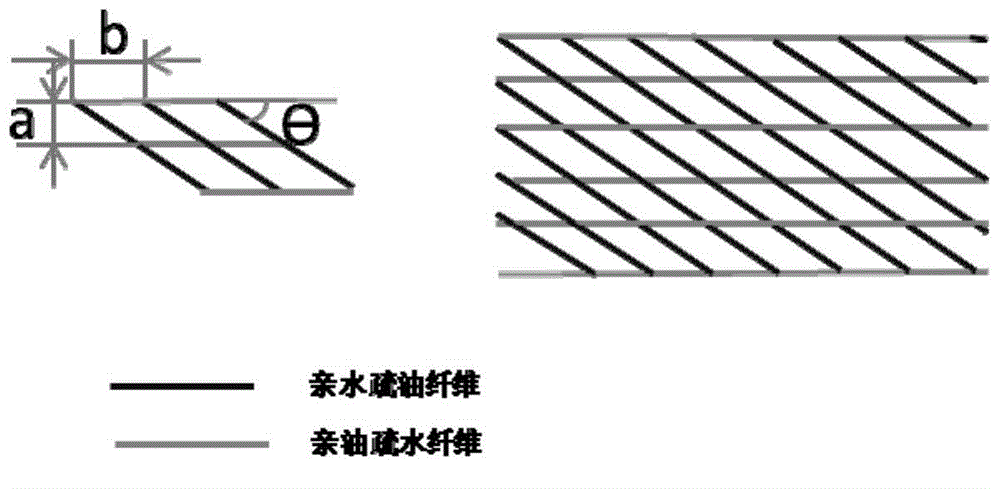

[0040] The schematic diagram of the above-mentioned device is shown in Figure 6 As shown, it includes housing 1, oil inlet 2, fluid rectifier 3, X-shaped braided layer 4 (fiber coalescence separation layer), corrugated reinforced separation layer 5, Ω-shaped braided layer 6 (fiber coalescing supplementary layer), Water bag 10 and purified oil phase outlet 7;

[0041] Wherein, the oil inlet 2 is at one end of the upper part of the housing 1, and the purified oil phase outlet 7 is at the other end of the upper part of the housing 1; the water bag 10 is at the bottom of the housing 1, and the water bag 10 is opposite to or slightly Relatively arranged with devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com