Constructed wetland heavy metal deionization purification system based on supercapacitor

A technology of artificial wetlands and supercapacitors, applied in chemical instruments and methods, multi-stage water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve problems such as small scope of application, small amount of treated water, secondary pollution, etc. Achieve the effect of restoring landscape ecological function, short treatment cycle and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

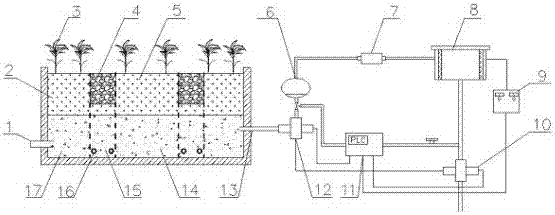

[0036]A supercapacitor-based heavy metal deionization purification system for constructed wetlands. Such as figure 1 As shown, the device is formed by connecting a horizontal subsurface flow constructed wetland (2) with a supercapacitor system through water pipes.

[0037] Such as figure 1 As shown, the horizontal subsurface flow constructed wetland (2) is composed of an upper layer (5) and a lower layer (17); the upper layer (5) is filled with sand and the lower layer (17) is filled with gravel, and the height ratio of the upper layer (5) and the lower layer (17) is (1~2): 1; the height of the horizontal underflow constructed wetland (2) is 0.7~0.8m.

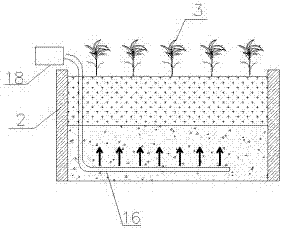

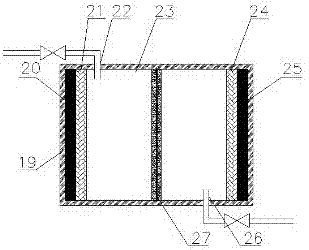

[0038] Such as figure 1 As shown, the horizontal subsurface flow artificial wetland (2) is composed of a natural reoxygenation channel area (4), a wetland treatment area (14) and an artificial oxygenation area (15). The length of the natural reoxygenation channel area (4) is equal to the length of the horizontal subsurface ...

Embodiment 2

[0052] A supercapacitor-based heavy metal deionization purification system for constructed wetlands. Except following technical parameter, all the other are with embodiment 1:

[0053] The horizontal subsurface flow artificial wetland (2) is composed of an upper layer (5) and a lower layer (17); the upper layer (5) is filled with sand and the lower layer (17) is filled with gravel, and the height ratio between the upper layer (5) and the lower layer (17) is (2~ 3): 1; the height of the horizontal subsurface flow constructed wetland (2) is 0.8~0.9m;

[0054] The width of the natural reoxygenation channel area (4) is 700-1000mm, the number of the natural reoxygenation channel area (4) is 3-5, and the distance between the centerlines of the natural reoxygenation channel area (4) is 7-10m;

[0055] The bottom of each artificial aeration zone (15) is horizontally provided with 3 or 4 aeration pipes (16), the center-to-center distance between the aeration pipes (16) is 150 ~ 250mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com