Compound degreaser for polymer flooding produced water and preparation method thereof

A degreaser and polymer technology, which is applied in the field of composite degreaser for polymer flooding produced water and its preparation, can solve the problems of complex and changeable operation modes, achieve the promotion of adsorption performance and interface modification ability, and reduce costs , to meet the effect of degreasing pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Degreaser AD 1 and its preparation method

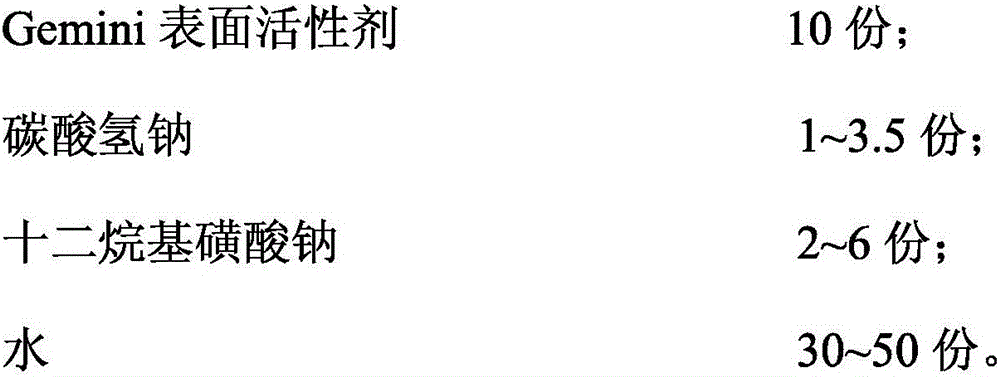

[0032] (1) Degreaser AD 1 The composition and its components are as follows:

[0033]

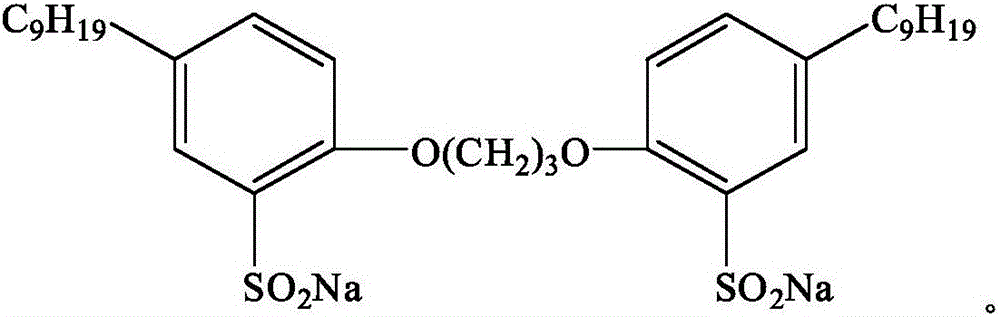

[0034] According to existing literature, the preparation method of described Gemini surfactant is as follows:

[0035]

[0036] (2) Degreaser AD 1 The preparation method is as follows:

[0037] ① Add 15 parts of water into the beaker, adjust the temperature to 52°C, slowly add 2 parts of sodium dodecylsulfonate, stir well, the stirring speed is 230rpm, and the stirring time is 20min;

[0038] ②Add 10 parts of Gemini surfactant to the above beaker, adjust the temperature to 53°C, stir evenly, the stirring speed is 400rpm, and the stirring time is 30min;

[0039] ③ Adjust the temperature to 68°C, add 1 part of sodium bicarbonate to the above beaker, stir evenly, the stirring speed is 350rpm, and the stirring time is 20min;

[0040] ④ Adjust the temperature to 45°C, pour 15 parts of water slowly, stir evenly, the stir...

Embodiment 2

[0041] Embodiment 2: Degreaser AD 2 and its preparation method

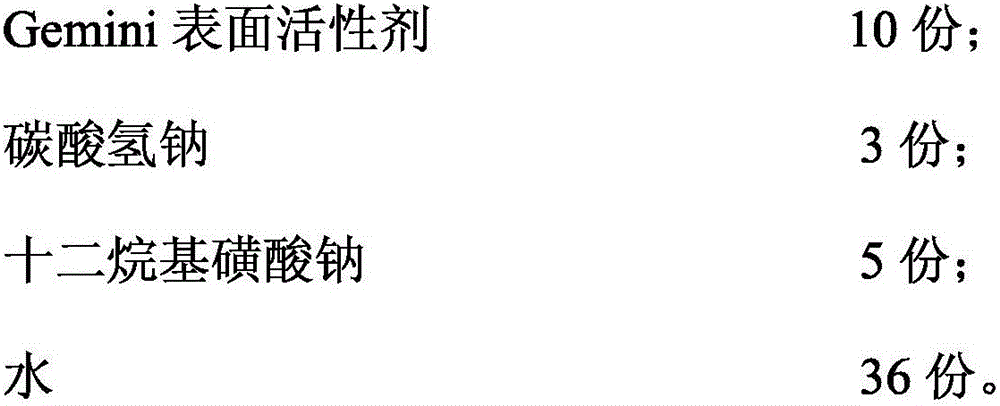

[0042] (1) Degreaser AD 2 The composition and its components are as follows:

[0043]

[0044] According to existing literature, the preparation method of described Gemini surfactant is as follows:

[0045]

[0046] (2) Degreaser AD 2 The preparation method is as follows:

[0047] ①Add 18 parts of water into the beaker, adjust the temperature to 48°C, slowly add 5 parts of sodium dodecylsulfonate, stir well, the stirring speed is 260rpm, and the stirring time is 25min;

[0048] ②Add 10 parts of Gemini surfactant to the above beaker, adjust the temperature to 57°C, stir evenly, the stirring speed is 450rpm, and the stirring time is 40min;

[0049] ③ Adjust the temperature to 65°C, add 3 parts of sodium bicarbonate to the above beaker, stir evenly, the stirring speed is 320rpm, and the stirring time is 23min;

[0050] ④ Adjust the temperature to 48°C, pour 18 parts of water slowly, stir evenly, the stir...

Embodiment 3

[0051] Embodiment 3: Degreaser AD3 and its preparation method

[0052] (1) Degreaser AD 3 The composition and its components are as follows:

[0053]

[0054] According to existing literature, the preparation method of described Gemini surfactant is as follows:

[0055]

[0056] (2) Degreaser AD 3 The preparation method is as follows:

[0057] ①Add 20 parts of water into the beaker, adjust the temperature to 45°C, slowly add 3 parts of sodium dodecylsulfonate, stir well, the stirring speed is 200rpm, and the stirring time is 28min;

[0058] ②Add 10 parts of Gemini surfactant to the above beaker, adjust the temperature to 50°C, stir evenly, the stirring speed is 480rpm, and the stirring time is 50min;

[0059] ③ Adjust the temperature to 75°C, add 2.5 parts of sodium bicarbonate to the above beaker, stir evenly, the stirring speed is 300pm, and the stirring time is 26min;

[0060] ④ Adjust the temperature to 52°C, pour 20 parts of water slowly, stir evenly, the stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com