A treatment process for high-concentration pectin wastewater

A treatment process and pectin wastewater technology, which is applied in the direction of food industry wastewater treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of affecting the treatment effect, high viscosity of pectin wastewater, high power consumption, etc., to improve safety and Stability, recovery and recycling, and the effect of reducing the viscosity of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

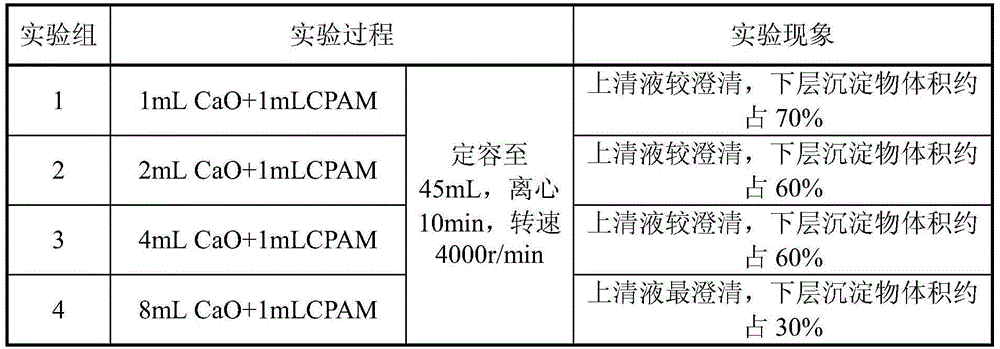

[0030] A process for treating high-concentration pectin waste water of the present invention comprises the following steps: drawing out the alkali-soaked water produced in the canned citrus fruit production process, first filtering the alkali-soaked water with multi-layer (usually 3 to 5 layers) gauze, That is, the water sample is pretreated, and then the composite flocculant is added to the filtered alkali immersion water and stirred at 30rpm for 10min, and then the solid-liquid separation is carried out by centrifugation at a centrifugal speed of 4000rpm and a centrifugation time of 10min to complete the treatment process.

[0031] In this embodiment, the experimental reagents and their concentrations are: CaO (5 g / L), CPAM (1 g / L).

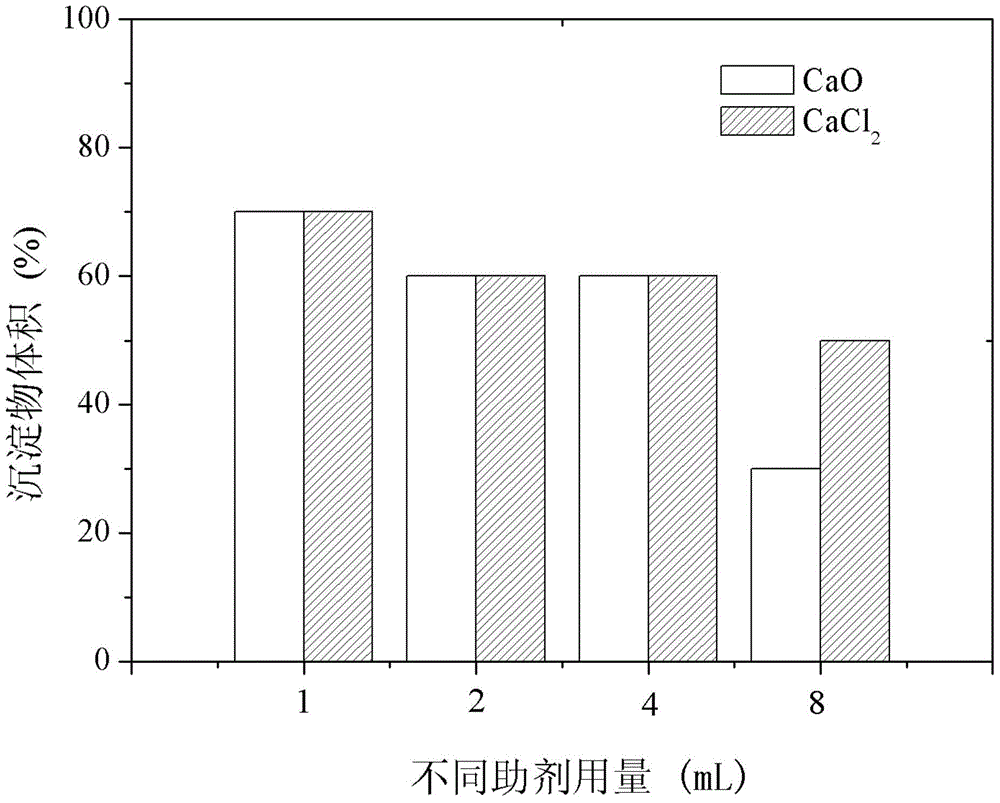

[0032] In the present embodiment, each 30mL (comprising the control group) of the alkaline immersion water sample after getting 4 groups of filtrations, adds reagent respectively by the requirement in Table 2, and experimental phenomenon is as T...

Embodiment 2

[0039]A process for treating high-concentration pectin waste water of the present invention comprises the following steps: drawing out the alkali-soaked water produced in the canned citrus fruit production process, first filtering the alkali-soaked water with multi-layer (usually 3 to 5 layers) gauze, That is, the water sample is pretreated, and then the composite flocculant is added to the filtered alkali immersion water, stirred at 30rpm for 10min, and then solid-liquid separation is carried out by centrifugation at a centrifugal speed of 4000rpm and a centrifugation time of 10min to complete the treatment process.

[0040] In this embodiment, the experimental reagent and its concentration are: CaCl 2 (5g / L), CPAM (1g / L).

[0041] In the present embodiment, get each 30mL (comprising control group) of the alkaline immersion water sample after getting 4 groups of filtrations, add reagent by the requirement in Table 4 respectively, experimental phenomenon is as Table 4 and fig...

Embodiment 3

[0060] A process for treating high-concentration pectin wastewater of the present invention investigates the effect of solid-liquid separation on alkali immersion treatment. The treatment process includes the following steps: lead out the alkali soaking water produced in the production process of canned citrus, first filter the alkali soaking water with three layers of gauze, then add a composite flocculant into the filtered alkali soaking water, and stir at 30 rpm for 10 minutes , and then complete the treatment process with different solid-liquid separation methods.

[0061] In this embodiment, the composite flocculant is specifically 8mL CaO+1mLCPAM, wherein CPAM (1g / L), Al 2 (SO 4 ) 3 (2g / L).

[0062] In this example, in order to compare the effects of different solid-liquid separation methods on the effect of alkali immersion water treatment, 4 groups of experiments were carried out, each taking 30 mL of water samples after mixing evenly, and the 4 groups of water samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com