A kind of tc4 titanium alloy surface electroplating copper process method

A process method, a technology of electroplating copper, which is applied in the field of surface modification of metal materials, can solve the problems of poor bonding between the non-toxic copper plating layer and the substrate, and achieve the effect of good bonding, high efficiency, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

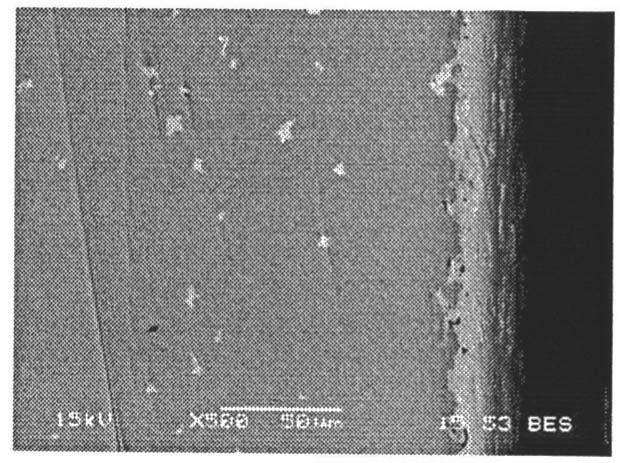

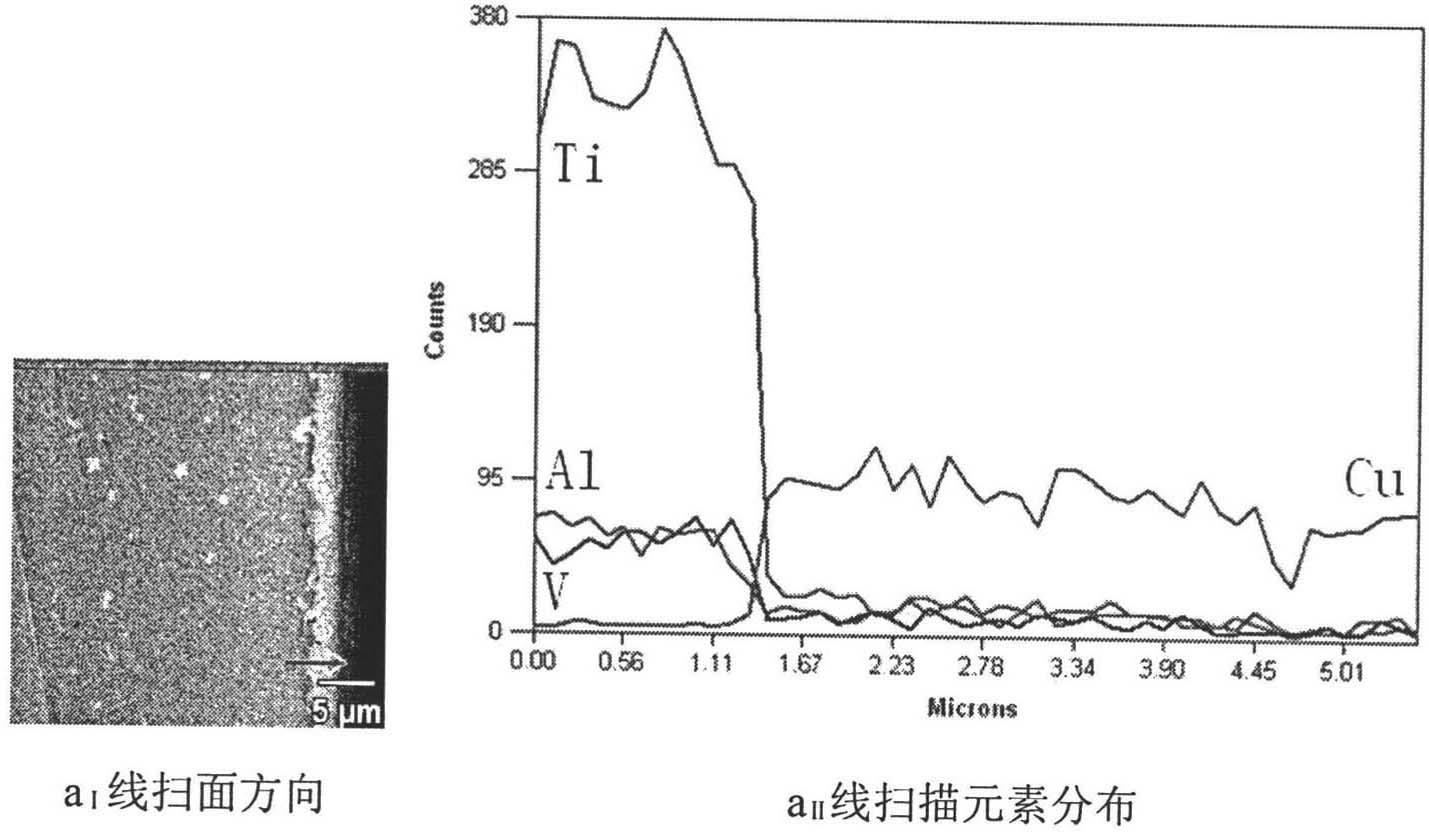

[0030] Copper plating on the surface of the TC4 titanium alloy sample with a specification of 25×20×5mm

[0031] Solution formula: ① Alkali washing solution: NaOH 75g / L; NaOH 3 PO 4 20g / L②Pickling solution: HF 100ml / L; HNO 3 300ml / L; distilled water 600ml / L③Activation solution: K 2 Cr 2 o 7 180g / L; HF 50ml / L④ Plating solution: CuSO 4 ·5H 2 O 150g / L; H 2 SO 4 60ml / L ⑤ Passivation solution: CrO 3 80g / L; NaCl 1.0g / L; H 2 SO 4 25ml / L.

[0032] Operation: ①Alkali washing: put the sample in the alkali washing solution with a temperature of 65°C and soak for 15 minutes; ②Water washing: rinse the sample after alkali washing with flowing water; ③Pickling: wash the sample Soak in pickling solution at room temperature for 2 minutes to carry out surface corrosion treatment; ④ Washing: Rinse the sample after pickling with running water; Soak in the solution for 25 minutes to perform surface activation treatment; ⑥Washing: Rinse the activated sample with running water; ⑦E...

Embodiment 2

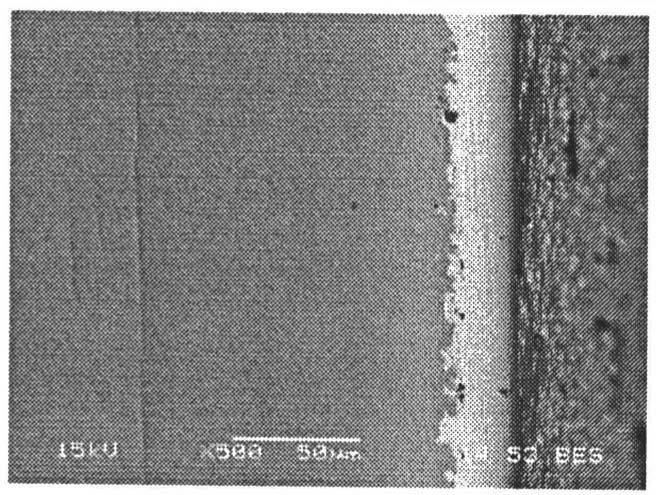

[0035] Copper plating on the surface of the TC4 titanium alloy sample with a specification of 25×20×5mm

[0036] Solution formula: ① Alkali washing solution: NaOH 85g / L; NaOH 3 PO 4 22.5g / L② Pickling solution: HF 150ml / L; HNO 3 350ml / L; distilled water 500ml / L③Activation solution: K 2 Cr 2 o7 210g / L; HF 65ml / L④ Plating solution: CuSO 4 ·5H 2 O 180g / L; H 2 SO 4 70ml / L ⑤ Passivation solution: CrO 3 85g / L; NaCl 1.5g / L; H 2 SO 4 27.5ml / L.

[0037] Operation: ①Alkali washing: put the sample in the alkaline washing solution with a temperature of 70°C and soak for 12 minutes; ②Water washing: rinse the sample after alkali washing with running water; ③Pickling: wash the sample Soak in pickling solution at room temperature for 1.5 minutes to carry out surface corrosion treatment; ④ Washing: Rinse the sample after pickling with running water; Soak in the solution for 22 minutes to carry out surface activation treatment; ⑥Washing: Rinse the activated sample with running w...

Embodiment 3

[0040] Copper plating on the surface of the TC4 titanium alloy sample with a specification of 25×20×5mm

[0041] Solution formula: ① Alkali washing solution: NaOH 100g / L; NaOH 3 PO 4 25g / L② Pickling solution: HF 200ml / L; HNO 3 400ml / L; distilled water 400ml / L③Activation solution: K 2 Cr 2 o 7 250g / L; HF 80ml / L④ Plating solution: CuSO 4 ·5H 2 O 200g / L; H 2 SO 4 80ml / L ⑤ Passivation solution: CrO 3 90g / L; NaCl 2.0g / L; H 2 SO 4 30ml / L.

[0042] Operation: ①Alkali washing: put the sample in the alkali washing solution with a temperature of 80°C, soak for 10 minutes; ②Water washing: rinse the sample after alkali washing with running water; ③Pickling: wash the sample Soak in pickling solution at room temperature for 1 minute to carry out surface corrosion treatment; ④ Washing: Rinse the sample after pickling with running water; Soak in the solution for 20 minutes for surface activation treatment; ⑥Washing: Rinse the activated sample with running water; ⑦Electropla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com