Treatment method for zero discharge of ionic liquid water solution

A technology of ionic liquid and treatment method, which is applied in the field of zero-discharge treatment of ionic liquid aqueous solution, can solve problems such as complicated process and difficult practical application, and achieve the effect of reliable process, high product quality and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

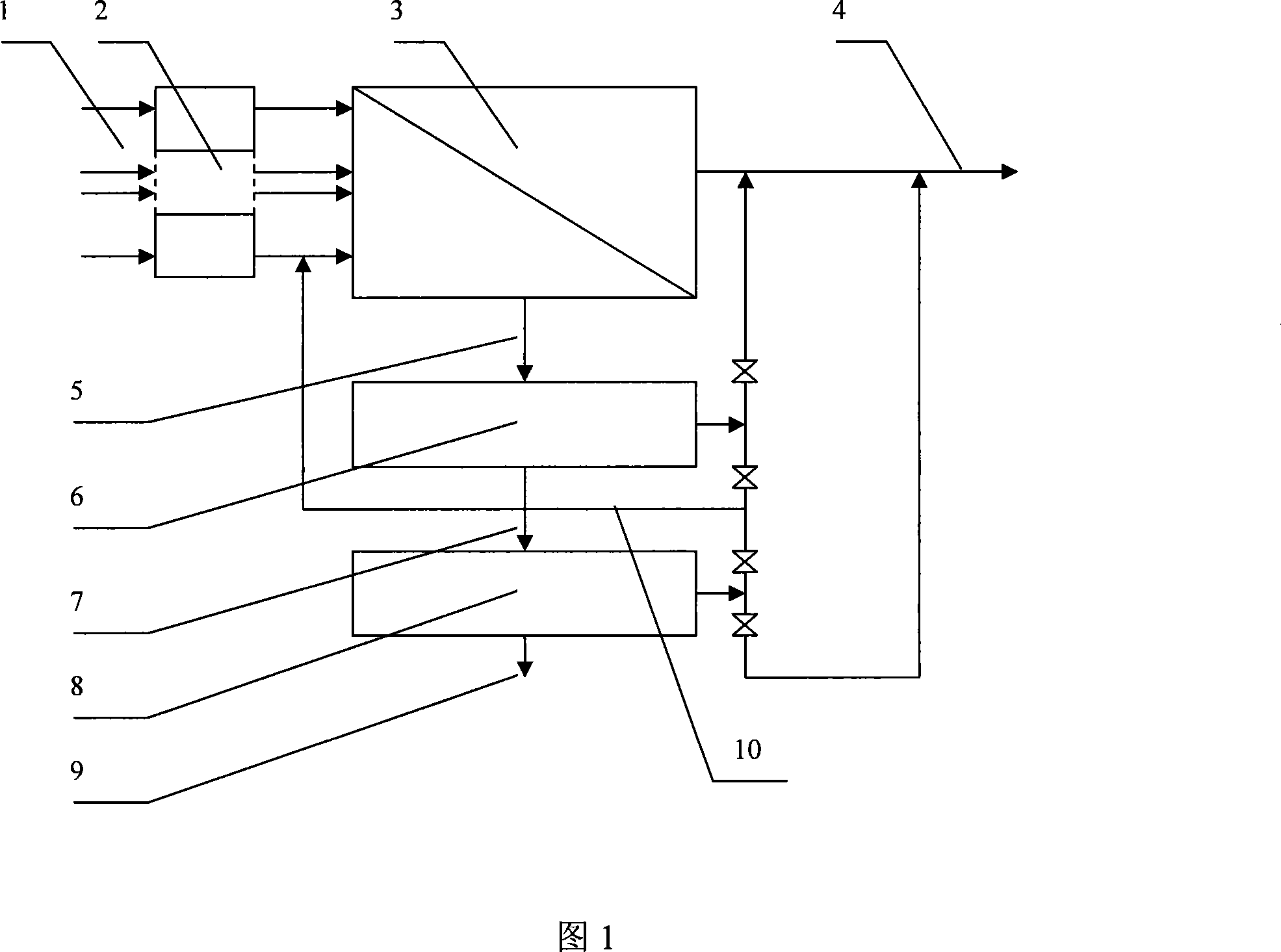

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, zero discharge treatment of ionic liquid aqueous solution

[0036] The dilute aqueous solution of 1-allyl-3-methylimidazolium chloride salt was treated with the JM 1812 roll-type membrane small-scale experimental machine. The reverse osmosis membrane used was polyamide reverse osmosis membrane, and the manufacturer was Dalian Yidong Membrane Engineering Equipment. Ltd. The concentration of the raw material solution was changed, and the concentration treatment of the reverse osmosis membrane was carried out in a circulation mode under a specified working pressure, and the content of the ionic liquid in the aqueous solution was measured with a conductivity and an ultraviolet spectrophotometer. The results are shown in Table 1.

[0037] Table 1 Concentration of ionic liquid 1-allyl-3-methylimidazolium dilute aqueous solution by reverse osmosis

[0038] Raw material concentration

Concentrate concentration

Permeate concentrat...

Embodiment 2

[0041] Embodiment 2, zero discharge treatment of ionic liquid aqueous solution

[0042] When the ionic liquid 1-allyl-3-methylimidazolium chloride salt is used as a solvent for small-scale production of cellulose spinning, the treatment process for the generated low-concentration ionic liquid aqueous solution includes the following four steps in sequence: pretreatment, two Stage circulation reverse osmosis membrane concentration treatment, one effect decompression evaporation treatment, one effect scraping film evaporation treatment.

[0043] First, the above-mentioned ionic liquid aqueous solution is divided into two levels for collection: the first level is a very dilute solution with a salt content of not more than 0.05-0.25%; the other level is a dilute solution with a concentration of not more than 5%. The above two solutions were subjected to coarse filtration and 0.5 micron fine filtration respectively.

[0044] After that, reverse osmosis membrane concentration treatm...

Embodiment 3

[0047] Embodiment 3, zero discharge treatment of ionic liquid aqueous solution

[0048] When using ionic liquid 1-allyl-3-methylimidazolium chloride salt as solvent to produce cellulose acetate, the product is washed with water for many times, and the obtained ionic liquid aqueous solutions with different concentrations are collected according to the following three levels: 1-5%, 0.1 -0.5%, 0.01-0.05%. In order to ensure the normal operation of the reverse osmosis device, the recovered solution is first adjusted to pH (adjusted to pH 6.5-7), decolorized, rough filtered, 0.5 micron fine filtered and 6K ultrafiltered.

[0049] Then use high-pressure, medium-pressure, and low-pressure three-stage reverse osmosis membrane concentration devices to process the above three ionic liquid aqueous solutions respectively. The reverse osmosis membrane used is a roll-type polyamide composite membrane, the membrane element is 8040 type, and the manufacturer is Dalian Yidong Membrane Enginee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com