Method for producing m-acetamino-N,N-diethyl aniline

A technology of acetaminoaniline and its production method, which is applied in the field of chemical synthesis of dye intermediates, can solve the problems of large energy consumption, increased product cost, and difficulty in reusing by-products, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

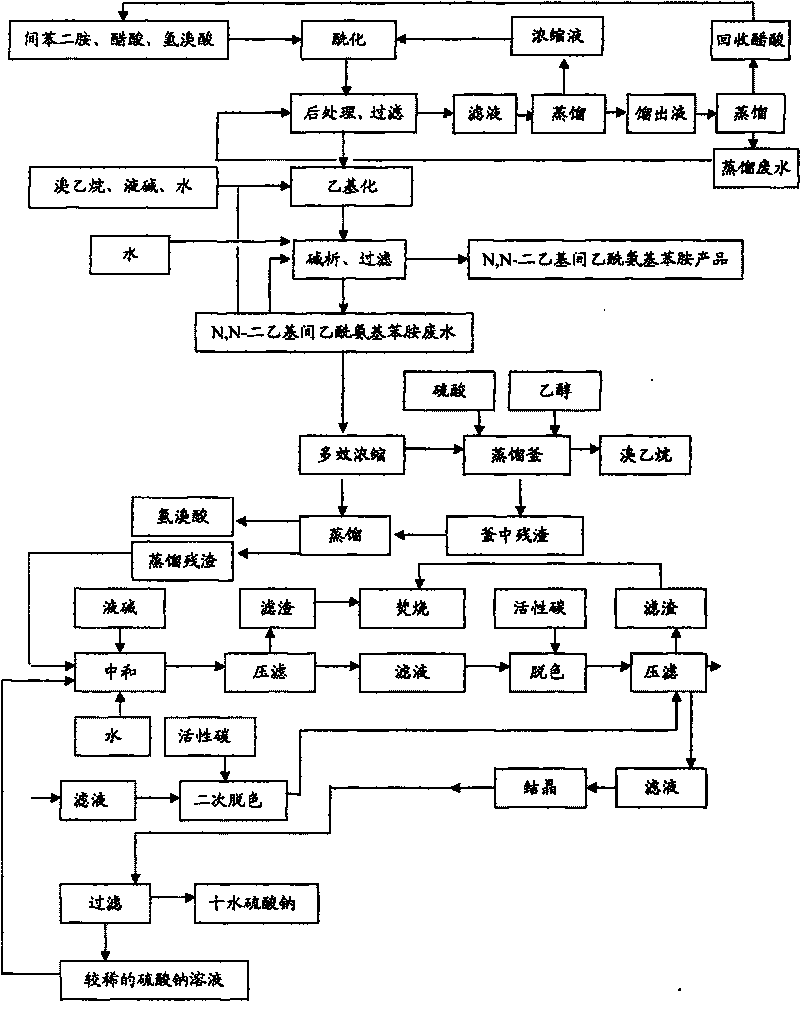

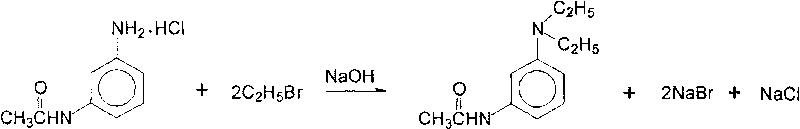

Method used

Image

Examples

Embodiment Construction

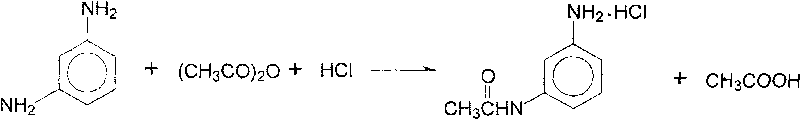

[0038] In 3 parts by weight of water, add 10 parts by weight of m-phenylenediamine, 17 parts by weight of 48% hydrobromic acid, then add 8.5 parts by weight of glacial acetic acid, add, and react at 90°C for 20 hours, (sampling detection, liquid phase Chromatographic detection of m-phenylenediamine peak ≤ 1.5% is qualified), cooling to 80°C, adding 4 parts by weight of water, cooling to 40°C, standing for 10 hours, filtering to obtain the acylate, and filtering the mother liquor for reuse as the next batch of acylation.

[0039] When filtering the mother liquor for reuse, you can add about 30 parts by weight of the mother liquor to the reactor, heat up, and distill out 10 parts by weight of water (which contains about 20% acetic acid, and the acetic acid that is steamed is purified in the acylation and salt-forming reaction through rectification. Apply mechanically), then add 10 parts by weight of m-phenylenediamine, 16 parts by weight of 48% hydrobromic acid, and 8.5 parts by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com