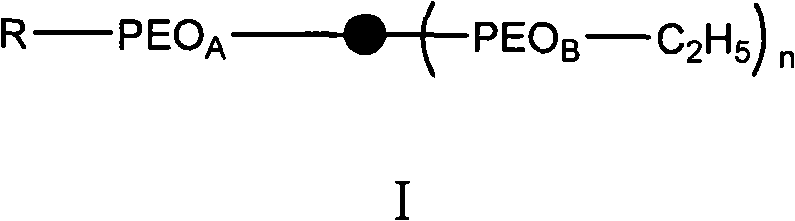

Multi-arm star-shaped polyethylene glycol containing single-activity functional groups and preparation method thereof

A polyethylene glycol and functional group technology, applied in the field of multi-arm star polyethylene glycol and its preparation, can solve problems such as inability to carry out specific reactions, and achieve simple preparation method, good application value and industrial prospect, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

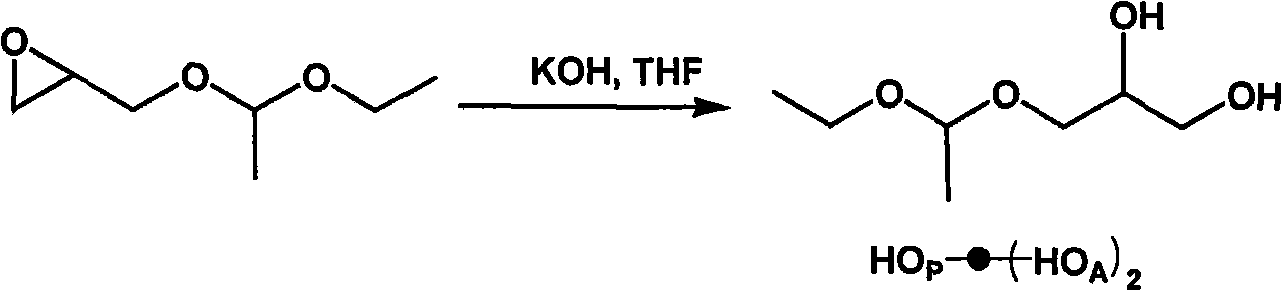

[0038] Preparation of small molecular compounds containing three active hydroxyl groups and one protected hydroxyl group

[0039] Under a nitrogen atmosphere, add 20 g of 2,2-iminobisethanol and 150 ml of THF to a 250 ml dry and clean round-bottom flask successively, and slowly dissolve 28 g of 1-ethoxyethyl 2 through a dropping funnel at room temperature, 3-Glycidyl ether was added, and the dropwise addition was completed within about 2.0 hours. After continuing to stir the reaction for 24 hours, the THF solvent was removed by rotary evaporation at 45°C. It was extracted and separated with ether and water, and the purity of the product was checked by thin-layer chromatography. Finally, a viscous colorless transparent liquid was obtained, which was sealed and stored for future use.

[0040]

[0041] 1 H NMR (CD 3 OD)d(ppm): 1.2(m, CH 3 CH 2 O-), 1.3 (m, CH 3 -CH-), 2.5-2.8(m, 6H(-CH 2 ) 2 -N-CH 2 -), 3.5-3.65 (m-CH 2 -), 3.8(m(-CH 2 ) 2 CH-OH), 4.7(m, -OCH(CH 3...

Embodiment 2

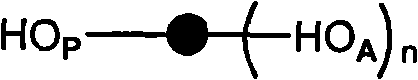

[0042] The preparation of the three-arm star-shaped polyethylene glycol (B 3 )

[0043] Add 0.50g of the above-mentioned small molecular compound, 30ml DMSO, 30ml THF, 2.8ml DPMK, and 10ml ethylene oxide into a dry and clean 300ml ampoule with a stirring magnet in sequence, and react at 40°C for 48h. Then, continue to add excess DPMK, stir well and then add bromoethane which is twice the molar amount of DPMK, and continue to react at 40°C for 24h. After the reaction, concentrate the polymer, add 100ml of methanol solvent to dissolve, then add 9ml of concentrated hydrochloric acid for hydrolysis reaction; react at room temperature for 3.0h, then spin off the solvent and extract with a large amount of dichloromethane, and then concentrate the organic layer after removing water , and finally precipitated with a large amount of anhydrous ether, filtered, and vacuum-dried to obtain a three-armed star-shaped polyethylene glycol containing an active hydroxyl group at the link.

[0...

Embodiment 3

[0046] Embodiment 3 The fourth arm end group is the preparation of the multi-arm star polyethylene glycol of hydroxyl group (AB 3 )

[0047] Dissolve 7.0 g of the three-arm star-shaped polyethylene glycol containing an active hydroxyl group at the above-mentioned link in 60 ml of DMSO and 60 ml of THF mixed solvent system, and transfer it to a dry and clean 500 ml ampoule with a stirring bar, and then slowly Add 3.5ml DPMK. Finally, 10ml of ethylene oxide was added, and the temperature was raised to 50°C for 48h. After the reaction was finished, the reaction was terminated with methanol, and the crude product was precipitated with anhydrous ether, filtered, and vacuum-dried to obtain the multi-armed star-shaped polyethylene glycol (AB 3 ).

[0048]

[0049] 1 H NMR (CD 3 OD)d(ppm): 1.13(m, CH 3 CH 2 O-), 2.5-2.8 (m, (-CH 2 ) 2 -N-CH 2 -), 3.51-3.77 (m, -CH 2 CH 2 O-of PEO).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com