Method for extracting iron titanium vanadium from high-titanium iron concentrate

A high-titanium, vanadium-iron technology, which is applied in the field of polymetallic mineral processing, can solve the problems of difficult recovery of refined vanadium, and achieve good social benefits, improved production efficiency, and fewer types and quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

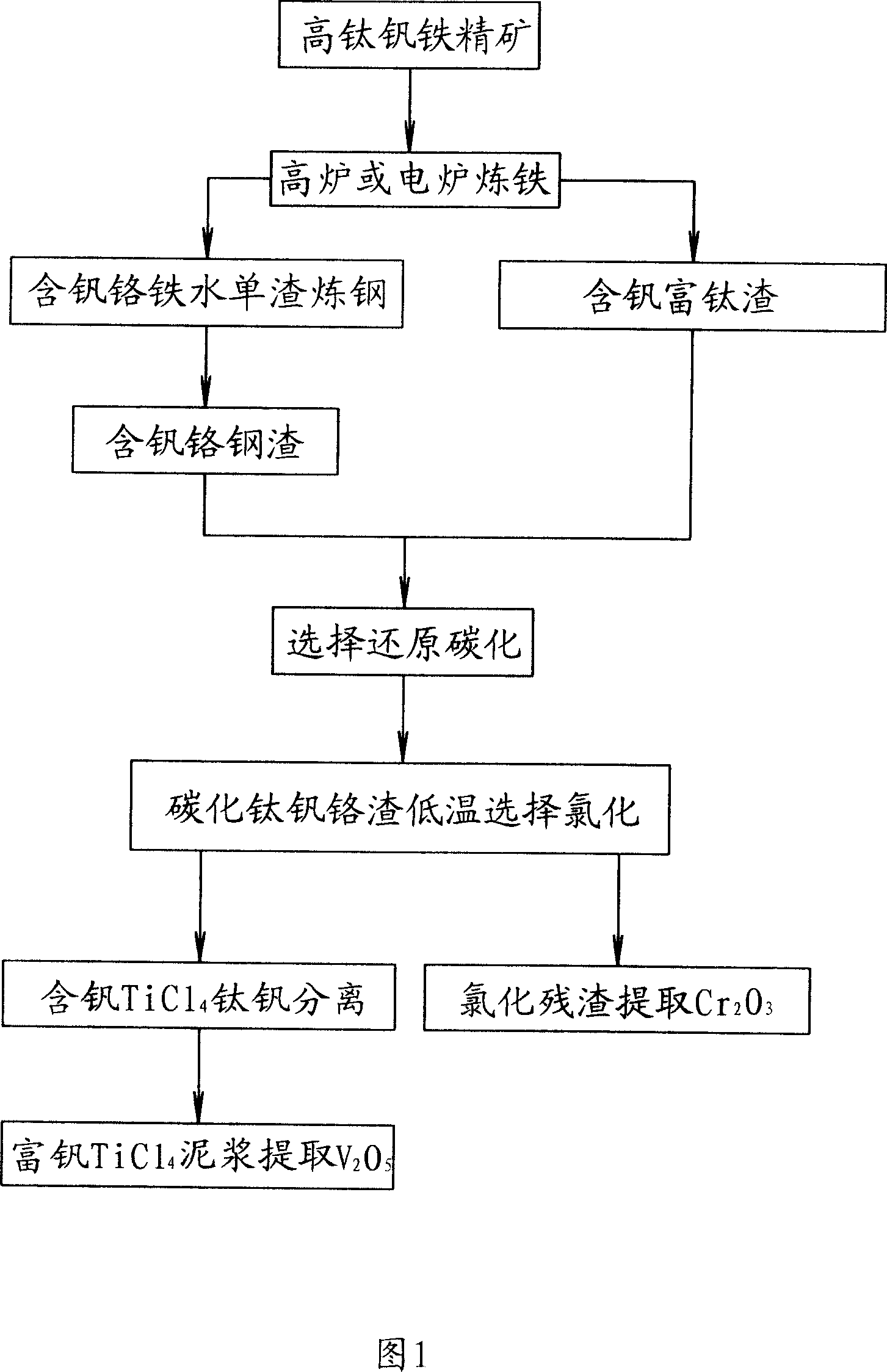

Image

Examples

Embodiment 1

[0048] High titanium vanadium iron concentrate (composition: TFe51.74%, FeO 29.65%, Fe 2 o 3 50.65%, V 2 o 5 0.56%, TiO 2 14.02%, Cr 2 o 3 0.45%, SiO 2 4.77%, Al 2 o 3 33.5%, CaO 1.79%, MgO 4.23%) are smelted in a pre-reduction hot-charging electric furnace with CaO supplementing carbon, and the rate of vanadium reduction into iron is controlled at 68% as the smelting end point. The composition of the molten iron produced is: C2.51%, V0.49%, Cr0.50%, Ti0.15%, Si0.16%, S0.06%. The composition of vanadium-containing titanium-rich slag is TiO 2 40%, V 2 o 5 0.35%, Cr 2 o 3 0.25%, CaO 13.60%, MgO 12.01%, SiO 2 17.06%, Al 2 o 3 13.43%, FeO 1.23%. Iron extraction rate and slag production rate are respectively: 500kg Fe / t·concentrate, 350kg vanadium-containing titanium-rich slag / t·concentrate. The vanadium-chromium-containing hot metal is used as the raw material for the production of vanadium-chromium-containing steel slag by steelmaking, and the vanadiu...

Embodiment 2

[0066] High-titanium ferrovanadium concentrate (composition: TFe 62.0%, FeO 30.6%, Fe 2 o 3 55.0%, V 2 o 5 0.57%, TiO 2 6.1%, Cr 2 o 3 0.75%, SiO 2 1.6%, Ae 2 o 3 2.5%, CaO 1.79%, MgO 2.6%) are smelted in a pre-reduction hot-charging electric furnace and CaO carbon supplement, and the smelting end point is controlled by controlling the rate of vanadium reduction into iron to 71%. The components of molten iron produced are: C 2.72%, V 0.38%, Cr 0.55%, Ti 0.18%, Si 0.16%, Si 0.20%. The composition of vanadium-containing titanium-rich slag is TiO 2 26.50%, V 2 o 5 0.62%, Cr 2 o 3 0.75%, CaO 17.50%, MgO 10.20%, SiO 2 20.6%, Al 2 o 3 19.31%, FeO 1.05%. Iron extraction rate and slag production rate are respectively: 610kg Fe / t·concentrate, 230kg vanadium-containing titanium-rich slag / t·concentrate. The vanadium-chromium-containing hot metal is used as the raw material for the production of vanadium-chromium-containing steel slag by steelmaking, and the v...

Embodiment 3

[0084] The blast furnace smelting composition is: TFe 51.52%, FeO3 2.26%, V 2 o 5 0.49%, Cr 2 o 3 0.03%, TiO 2 12.73%, SiO 2 3.37%, MgO 4.66%, Al 2 o 3 4.59%, S 0.24%) high-titanium ferro-vanadium concentrate, the production of vanadium-chromium-containing iron water is accompanied by production of vanadium-containing titanium-rich slag, and the rate of vanadium reduction into iron is 75%. The components of vanadium-chromium-containing hot metal are: C 4.3%, SiO 20.2%, Ti 0.2%, V 0.34%, Cr 0.06%. The composition of vanadium-containing titanium-rich slag is TiO 2 23.10%, V 2 o 5 0.27%, Cr 2 o 3 0.014%, CaO2 6.80%, FeO 0.5%, MgO 8.08%, SiO 2 23.336%, Al 2 o 3 13.80%, TFe 2.1%, slag to iron = 0.8. The vanadium-chromium-containing hot metal is used as the raw material for the secondary production of chromium-containing steel slag, and the vanadium-rich titanium-rich slag is used as the raw material for the production of titanium carbide vanadium-chromium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com