Artificial stone with photocatalysis

A technology of artificial stone and curing agent, which is applied in the direction of manufacturing tools, mixing operation control, chemical instruments and methods, etc. It can solve the problems of reducing the strength of finished materials, high cost, and increasing the manufacturing cost of finished products, so as to improve the curing speed and production cost. The effect of low and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

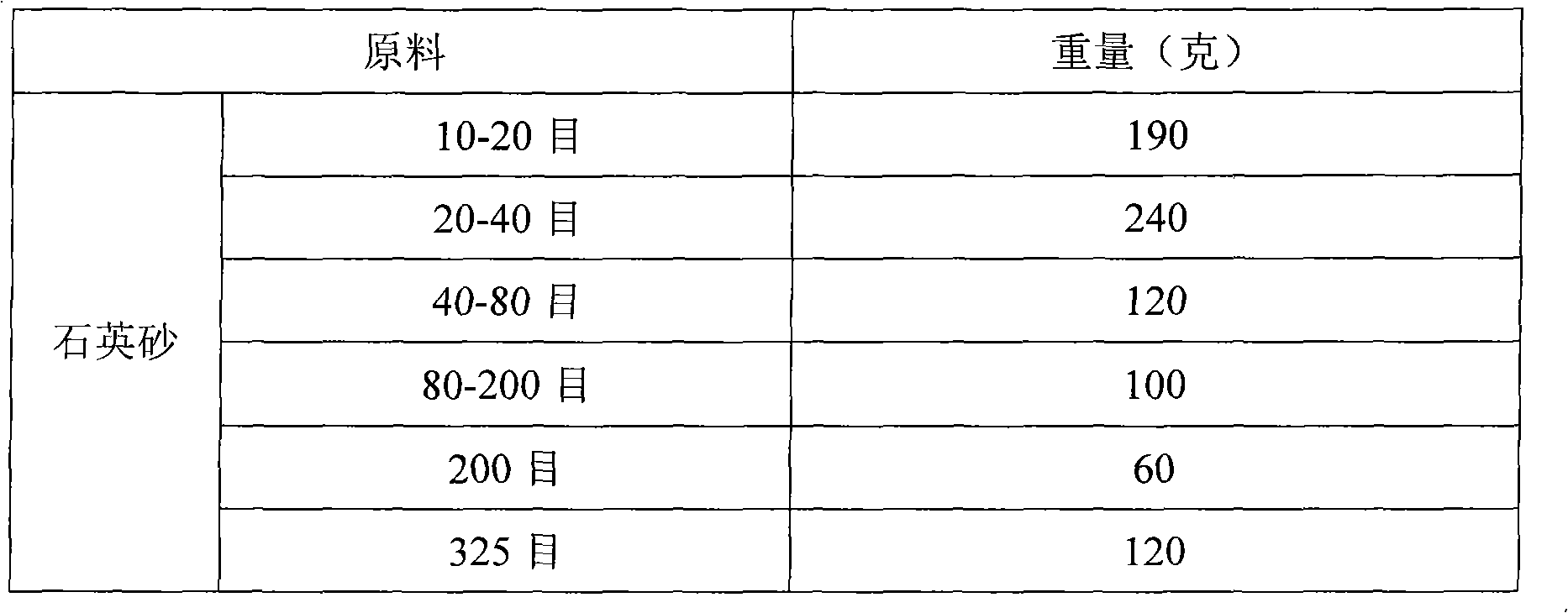

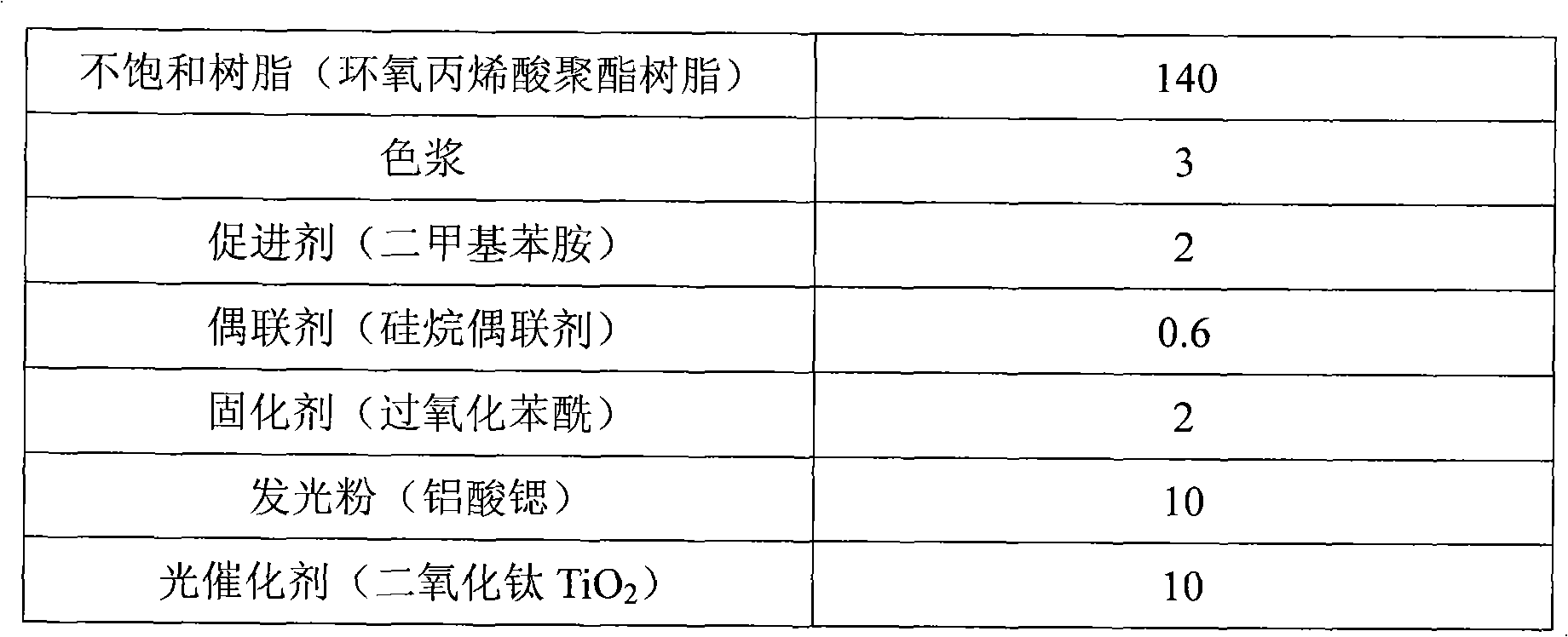

[0030] Example 1: The production process of luminous environmental protection artificial quartz stone plate. Take the total weight of raw materials as 1kg as an example. Raw material ratio as shown in Table 1

[0031] Ratio of raw materials in table 1 embodiment 1

[0032]

[0033]

[0034] Weigh 3 grams of color paste, 10 grams of luminescent powder, and 10 grams of photocatalyst, add them to 140 grams of resin, stir evenly, then add 120 grams of 325-mesh quartz sand, stir well, and then adjust the order from large to small according to the number of meshes. Add quartz of other meshes in sequence. After each addition of quartz, it needs to be fully stirred. Finally, add accelerator and curing agent. After stirring quickly and evenly, the raw material for board making is obtained, and poured into the board making mold. Send the mold into the vacuum box for vacuuming. When the air pressure reaches -0.1MPa, keep it for about 8 minutes, then take out the mold, and sprinkl...

Embodiment 2

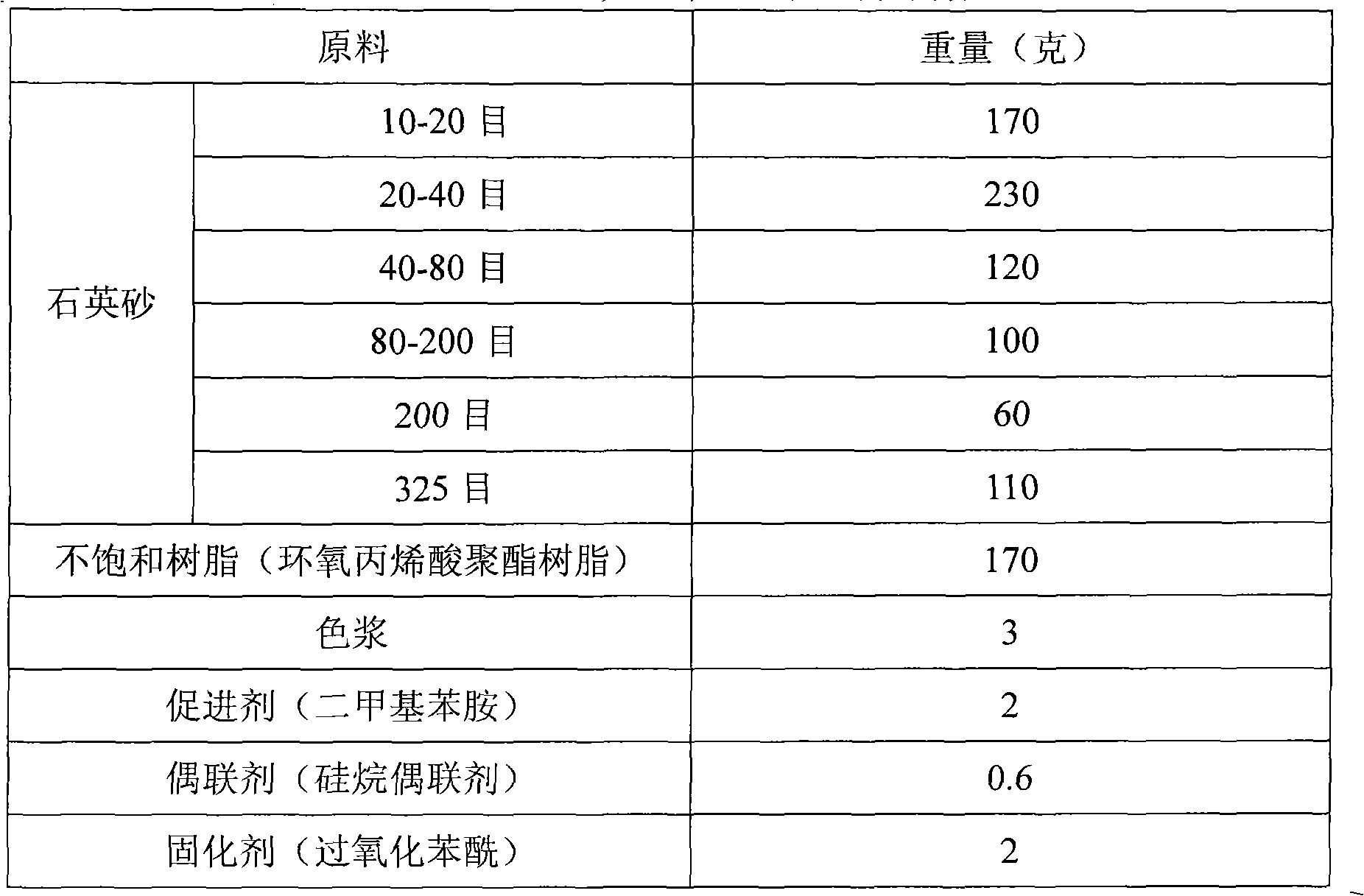

[0036] Example 2: The production process of artificial quartz stone plates containing luminous particles, taking the total weight of raw materials as 1kg as an example. The ratio of raw materials is shown in Table 2.

[0037] Raw material proportioning in table 2 embodiment 2

[0038]

[0039]

[0040] The first is the process of making luminous particles: 40g of unsaturated resin, 25g of light-storing luminescent powder, 30g of aluminum hydroxide powder, 0.4g of accelerator, 0.4g of curing agent, fully stirred, mixed evenly, poured into the mold, and Put the mold into the vacuum box for vacuuming, and keep it out of the box for 3 to 5 minutes under the condition that the vacuum degree reaches -0.1MPa, and leave it at room temperature for a period of time to make it completely solidified, and then crush and sieve to obtain 20-40 Purpose luminous powder particles. Take 30 grams of 20-40 mesh luminous powder particles and mix them with 250 grams of 20-40 mesh quartz ston...

Embodiment 3

[0041]Embodiment 3: Characterization of photocatalytic effect (taking the effect of decomposing acetaldehyde as an example).

[0042] Grind the prepared artificial stone into a 10cm×10cm×1cm plate, first measure its initial mass m 1 , and then put it into a closed transparent container with a volume of 860ml, and inject 1ml of 40% acetaldehyde solution, absorb it in a dark environment for 2 hours, and measure the mass of the plate in m 2 , and then placed the reactor in the sunlight for 1 hour to carry out the photocatalytic reaction, and the mass of the plate was measured m 3 , and finally re-placed in a dark environment to continue the photocatalytic reaction for 1 hour under the action of its own night light, and its mass m was measured 4 . It can be known that the mass of acetaldehyde adsorbed by the plate sample is (m 2 -m 1 ), the mass of acetaldehyde decomposed by photocatalysis under sunlight irradiation is (m 2 -m 3 ), the mass of acetaldehyde that continues to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com