Fiber reinforcing times force stone decoration product and production method thereof

A decorative product and fiber-reinforced technology, which is applied in the field of fiber-reinforced Beilistone decorative products and their production, can solve the problems of difficult molding process, low flexural strength, low impact strength, etc., achieve high durability and flame retardancy, expand Use field, good surface waterproof and antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

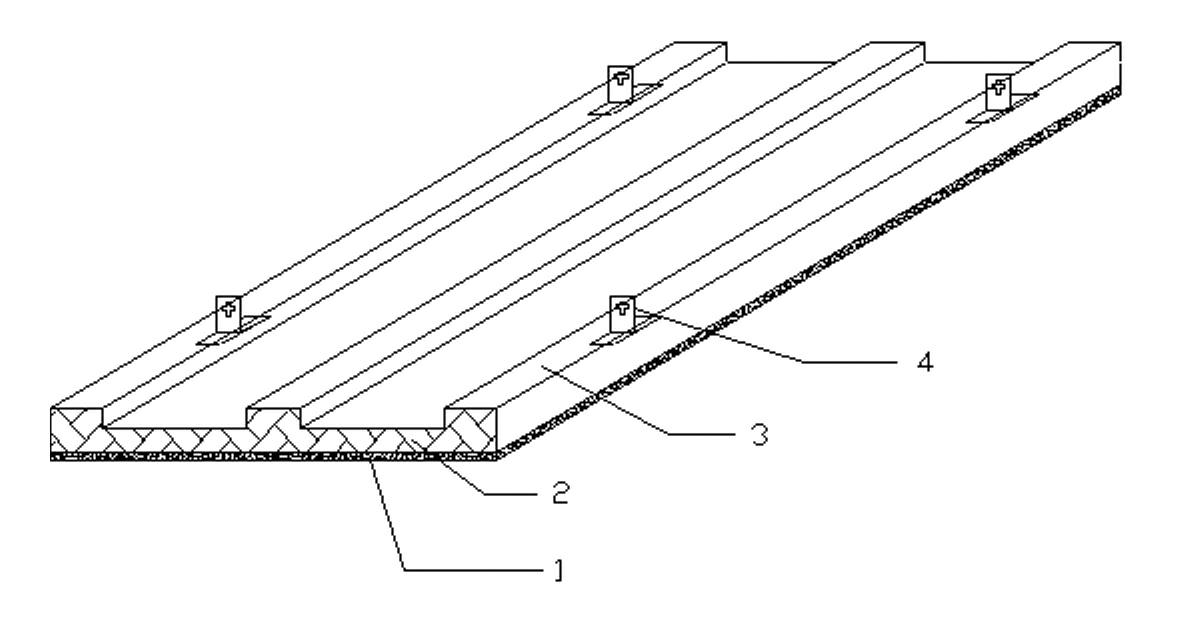

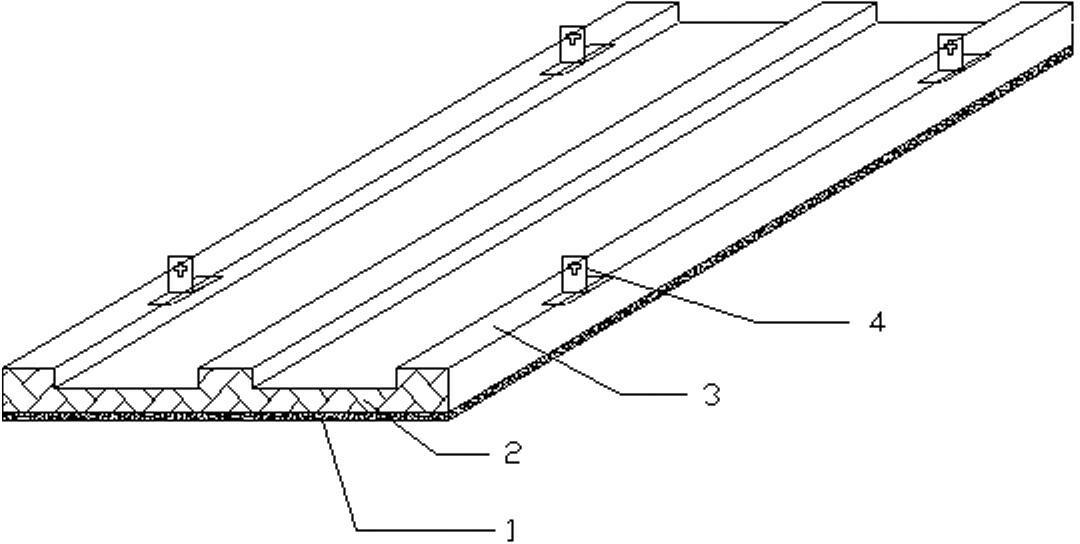

[0059] 1. Mix natural stone powder 10kg (10%), artificial colored sand 33kg (33%), cement 30kg (30%), water 20kg (20%), redispersible latex powder 4kg (4%), water reducer naphthalene sulfonate Salt formaldehyde condensate 0.4kg (0.4%), early strength agent sulfate 0.2kg (0.2%), retarder sodium tetraborate 0.2kg (0.2%), expansion agent sulfoaluminate 0.2kg (0.2%), Mix 1kg (1%) of fly ash, 0.7kg (0.7%) of nylon fiber, and 0.3kg (0.3%) of pulp fiber, and make the peili stone decorative layer slurry after stirring evenly;

[0060] 2. Add the configured Beili stone decorative layer mortar into the mold by pouring, and make it dense and smooth by vibrating and rolling;

[0061]3. Mix cement 28kg (28%), sand 45kg (45%), glass fiber 1.5kg (1.5%), PU fiber 0.5kg (0.5%), carbon fiber 0.5kg (0.5%), redispersible latex powder 5kg ( 5%), water reducing agent naphthalenesulfonate formaldehyde condensate 0.3kg (0.3%), early strength agent sulfate 0.1kg (0.1%), retarder molasses 0.1kg (0.1%)...

Embodiment 2

[0068] 1. Artificial stone powder 29kg (29%), natural colored sand 20kg (20%), cement 25kg (25%), water 11kg (11%), mineral pigment 3kg (3%), polypropylene emulsion 5kg (5%), Water reducer sulfonated melamine formaldehyde condensate 0.5kg (0.5%), antifreeze agent calcium chloride 0.5kg (0.5%), thickener hydroxypropyl methylcellulose 0.5kg (0.5%), retarder wood calcium Mix 0.5kg (0.5%), silica fume 3kg (3%), and slag 2kg (2%), mix well, and make peili stone decorative layer slurry;

[0069] 2. Add the configured Beili stone decorative layer mortar into the mold by pouring, and make it dense and smooth by vibrating and rolling;

[0070] 3. Put 25kg (25%) of cement, 50kg (50%) of sand, 2kg (2%) of glass fiber, 1kg (1%) of basalt fiber, 1kg (1%) of PP fiber, 4kg (4%) of polypropylene emulsion, and Water agent sulfonated melamine formaldehyde condensate 0.3kg (0.3%), early strength agent nitrite 0.2kg (0.2%), antifreeze agent calcium chloride 0.3kg (0.3%), thickener hydroxyethyl c...

Embodiment 3

[0077] 1. Natural stone powder 30kg (30%), natural colored sand 40kg (40%), cement 20kg (20%), water 5kg (5%), mineral pigment 2.5kg (2.5%), metakaolin 2kg (2%) , 0.5kg (0.5%) of PP fiber, mixed evenly, and made into a paste for the peili stone decorative layer;

[0078] 2. Add the configured Beili stone decorative layer mortar into the mold by pouring, and make it dense and smooth by vibrating and rolling;

[0079] 3. Mix cement 50kg (50%), sand 25kg (25%), glass fiber 1kg (1%), nylon fiber 0.5kg (0.5%), styrene-acrylic emulsion 2kg (2%), water reducing agent polycarboxylic acid 0.5 kg (0.5%), early strength agent triethanolamine 0.3kg (0.3%), antifreeze agent potassium carbonate 0.3kg (0.3%), thickener hydroxypropyl methylcellulose 0.2kg (0.2%), retarder four Mix 0.2kg (0.2%) of sodium borate with 20kg (20%) of water, and stir evenly to make fiber-reinforced cement slurry;

[0080] 4. Add the fiber-reinforced cement slurry into the mold of the peili stone decorative layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com