Reversible and flexible liner for imprinting a decorative pattern on a malleable surface and a method of using same

a flexible, malleable surface technology, applied in the direction of artificial islands, construction, foundation engineering, etc., can solve the problems of inability to withstand repeated use, prior art liners tear very easily, and end users of liner cannot remove liner from plywood board, etc., to achieve the effect of not cutting the liner and being easy to remov

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

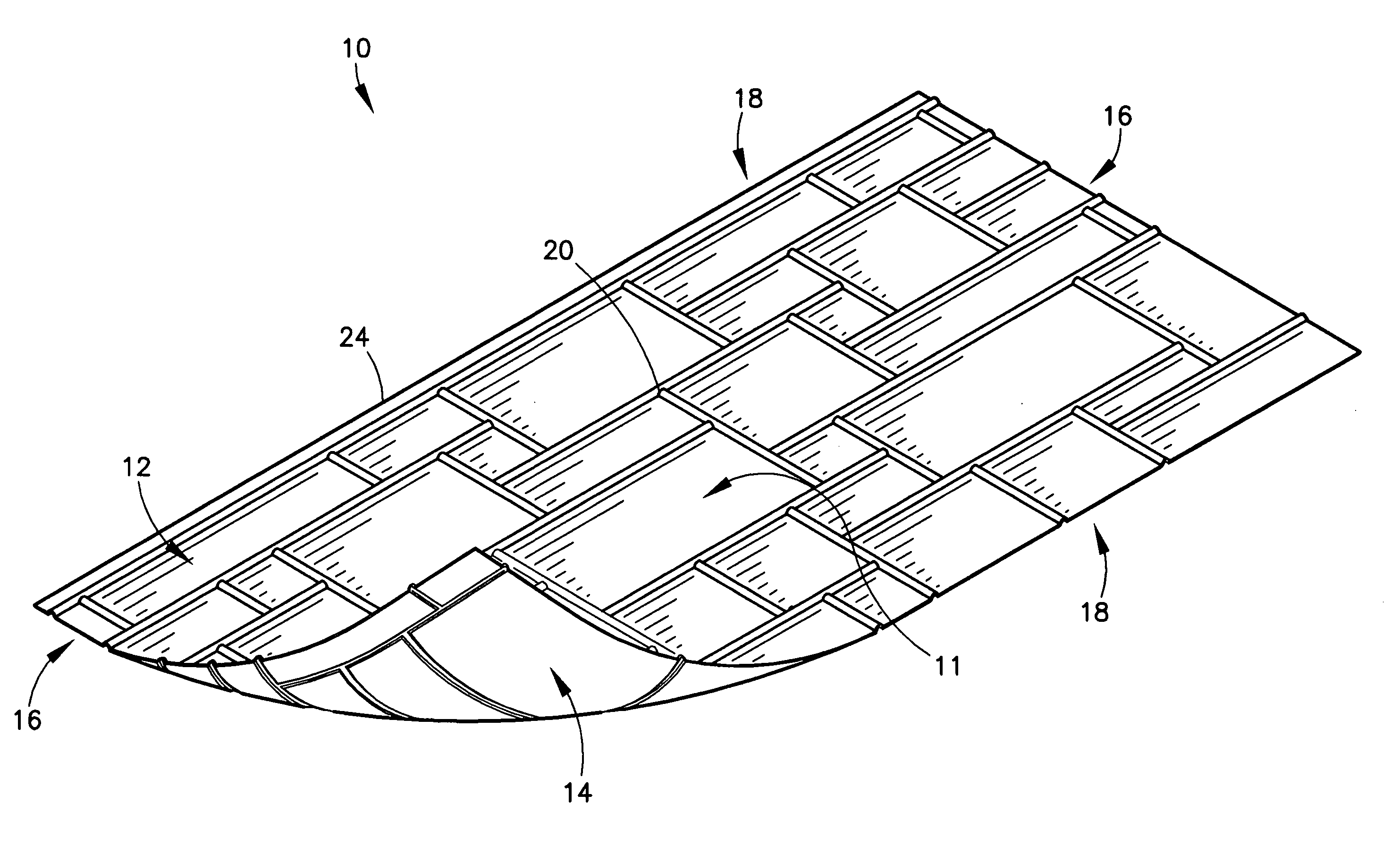

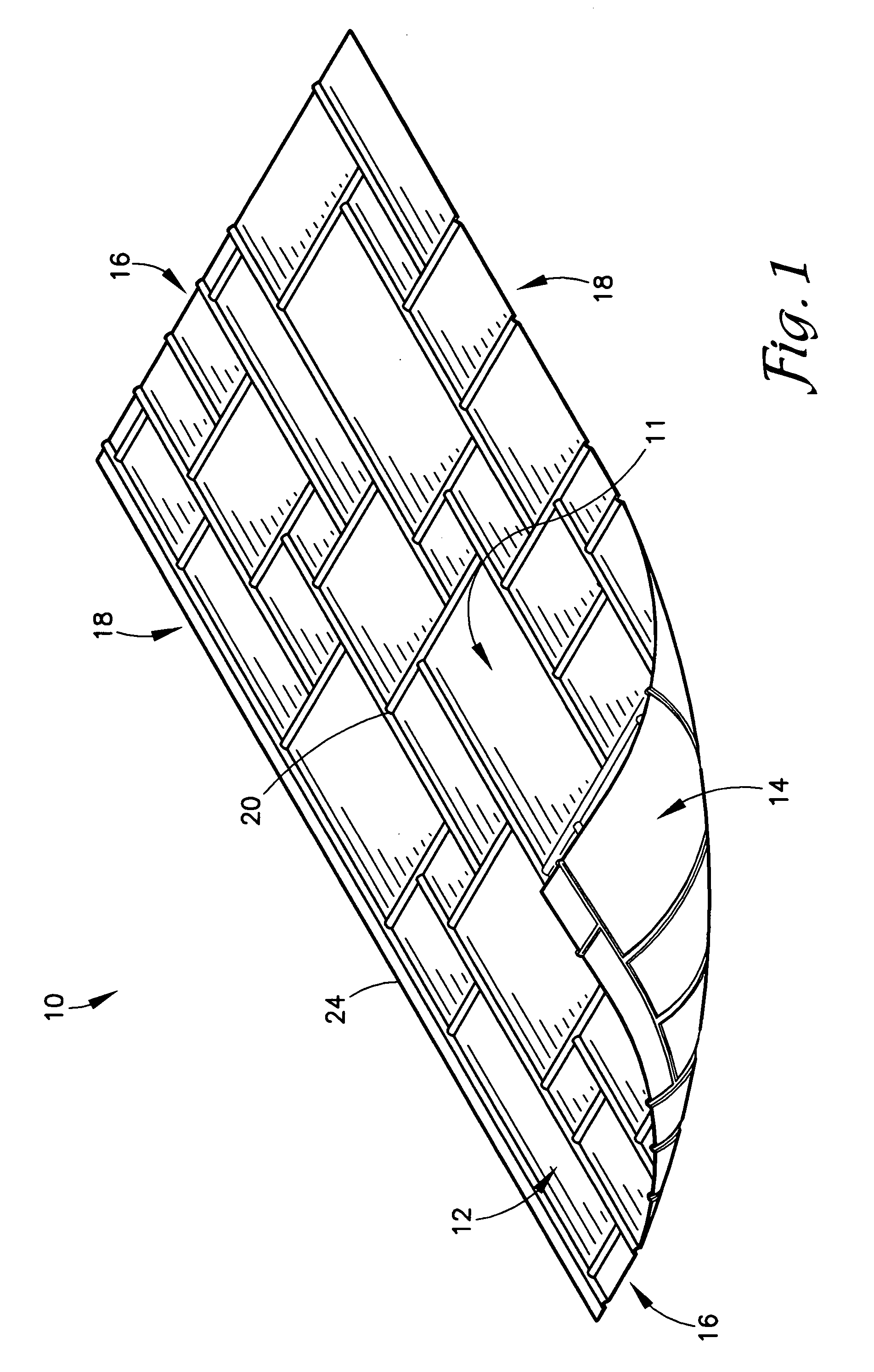

[0030] Referring to FIGS. 1 through 7, a liner 10 for forming decorative patterns on a malleable surface, such as concrete, and a method of doing same is constructed in accordance with a first preferred embodiment of the present invention. Although the liner 10 may be used to imprint any malleable surface, the liner 10 is ideally configured for imprinting concrete surfaces, and therefore, imprinting of only concrete surfaces will hereinafter be discussed. It is understood, however, that the liner 10 and method of using same of the present invention may be used on all malleable surfaces.

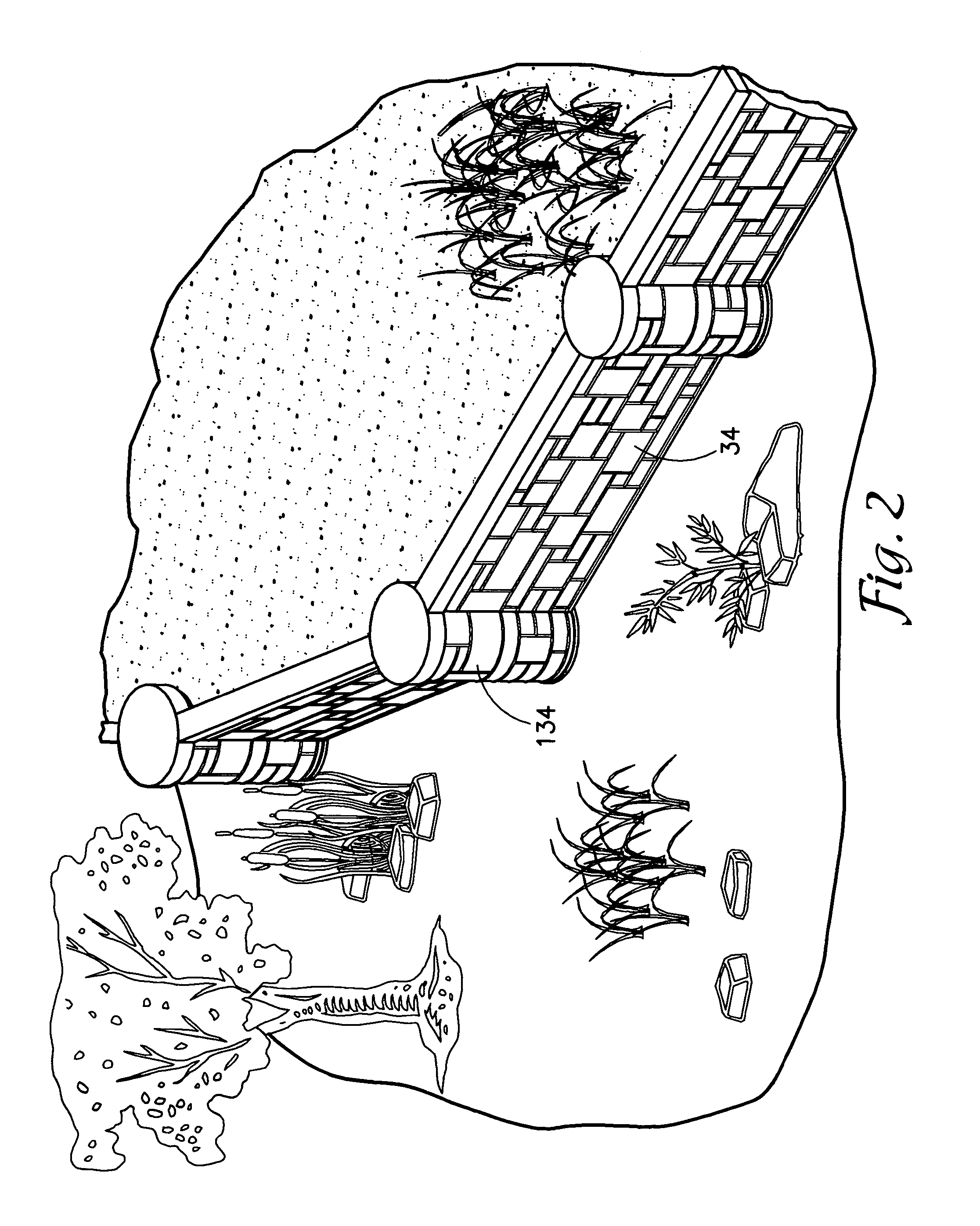

[0031] Use of the liner 10 in conjunction with the hardening of a wetted, flowable material, such as concrete, produces a stone, brick, rock, or marble-like appearance on the face of the concrete. The liner 10 may be used to imprint decorative patterns on both generally flat and generally curved surfaces, as illustrated in FIG. 2 and as illustrated in FIG. 1 of U.S. application Ser. No. 10 / 423,619, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com