Masonry anchoring system

a technology of masonry anchoring and jointing, which is applied in the direction of walls, building components, pillars, etc., can solve the problems of jointing having a detrimental effect on the structural stability of the wail structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Prior Art

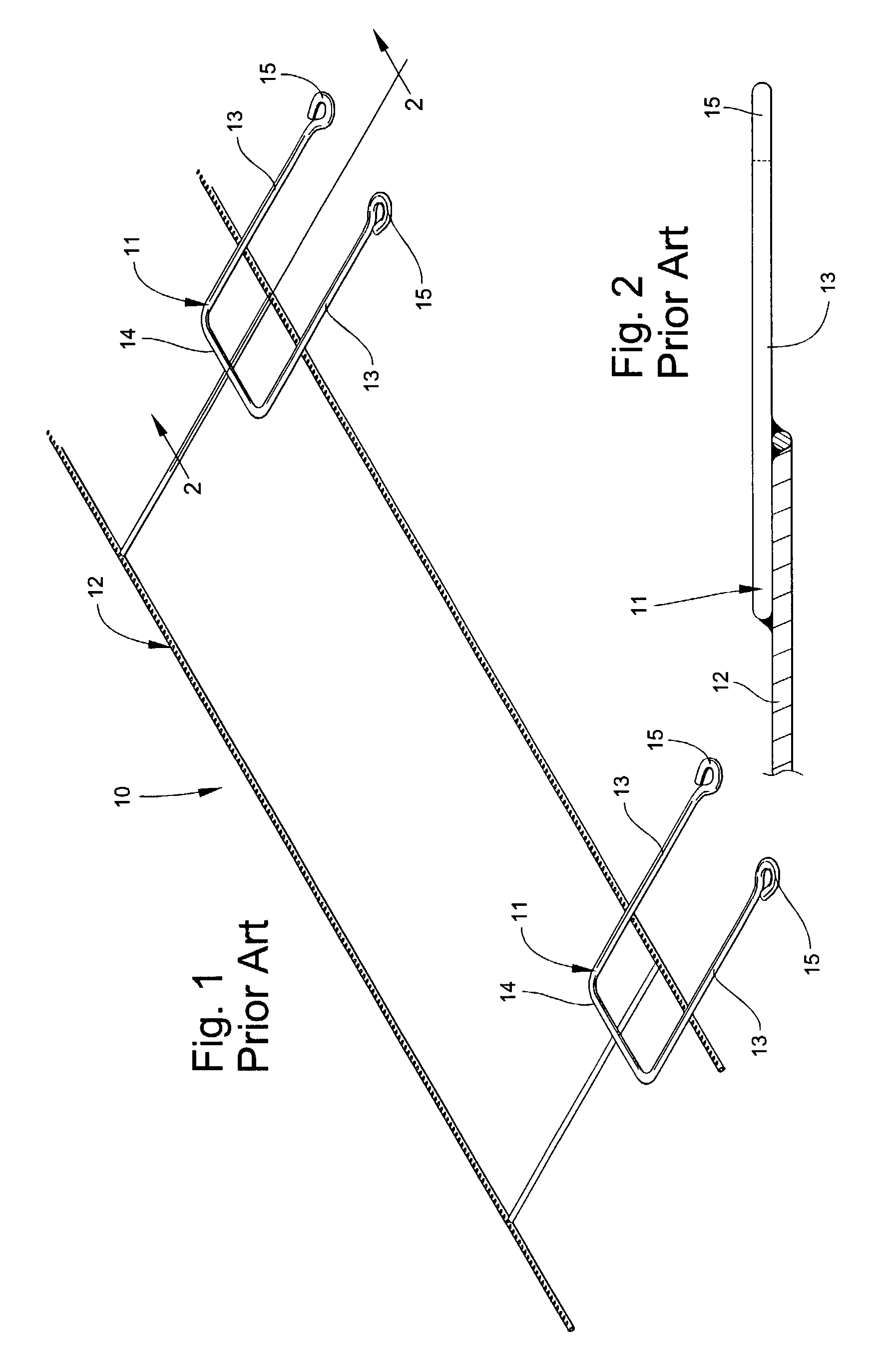

[0031] Referring now specifically to the drawings, a prior art masonry anchor is illustrated in FIG. 1, and shown generally at reference numeral 10. The prior art masonry anchor comprises U-shaped wire bracket 11 affixed on a ladder-type support frame 12. The U-shaped bracket 11 has a pair of parallel elongate arms 13 connected by a cross wire 14 extending transversely from the support frame 12. Eyes 15 are formed at the ends of the elongate arms 13, and shaped to receive a complimentary connecting member, such as a wall tie.

[0032] As shown in FIG. 2, the U-shaped bracket 11 is welded to one surface of the support frame 12, and occupies a different horizontal plane than the support frame 12. This increases the overall thickness of the anchor 10, resulting in less space available for filling mortar. The support frame 12 is typically comprised of a metal wire having a thickness of 0.148 inch, and the bracket 11 generally has a thickness of 0.187 inch, yielding a total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com